ENGINE

SPEED

I

50

STANDARD

The engine governor maintains a constant engine

speed under various load conditions to limit variations

in generator output voltage and frequency. Engine

speed variations directly affect the frequency and to a

lesser extent the output voltage of the generator. An

increase in engine speed

will

cause a corresponding

increase in generator frequency and a decrease in

engine speed

will

cause a corresponding decrease in

frequency. Voltage is held fairly constant by the voltage

regulator when small variations in engine speed occur.

Contact with moving parts can cause

b@!%l

severe personal injury. Keep

clothing, jewelry, hands, and fingers clear when work-

ing on the generator set

A

hot

muffler and other generator set

lliEFSl

components can cause severe

burns. Always allow the generator set to cool before

touching any components.

Engine Speed Check and Adjustment

Disconnect all loads from the generator set. An accurate

frequency meter should be connected to the generator

output receptacle. Check and adjust the engine speed

as follows:

1.

Start the engine. Make sure the speed control lever

is in the high speed position on Standard models

and that the Idlematic is

Off

on Pro models. Operate

the generator set with no-load until it is warm. Refer

to Figure

4-7.

2.

Check the no-load frequency for a normal reading

of 63.5 Hz

+

or

-

0.5

Hz (3780 to 3840 RPM).

3.

If

an abnormal reading is measured, adjust the

speed as follows:

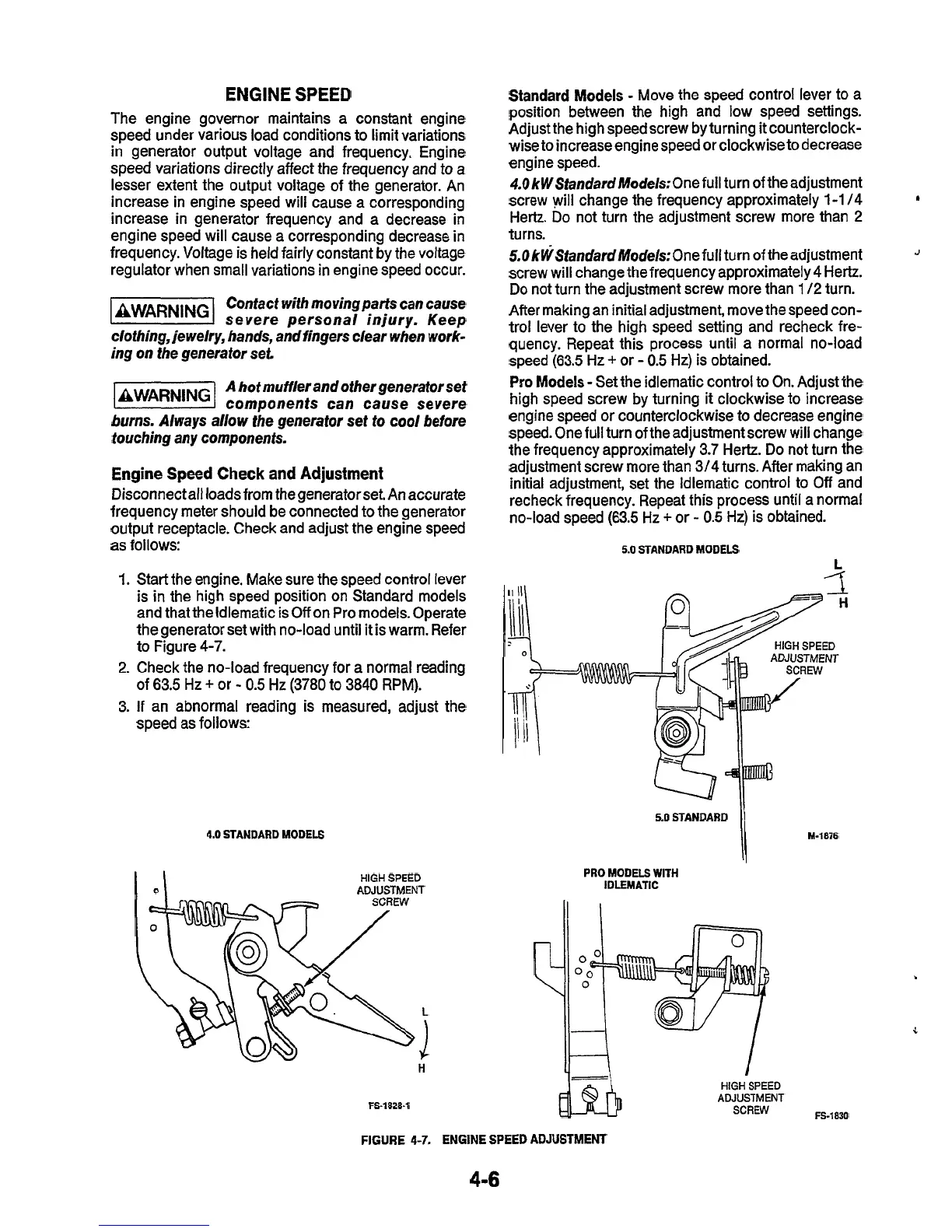

4.0

STANDARD MODELS

HIGH

SPEED

ADJUSTMENT

FS-1828-1

Standard Models

-

Move the speed control lever to a

position between the high and low speed settings.

Adjust the high speed screw by turning it counterclock-

wise

to

increase engine speed

or

clockwise to decrease

engine speed.

4.0kWSfandardModels:Onefull

turn of the adjustment

screw will change the frequency approximately

1-1

/4

Hertz.

Do

not turn the adjustment screw more than

2

turns.

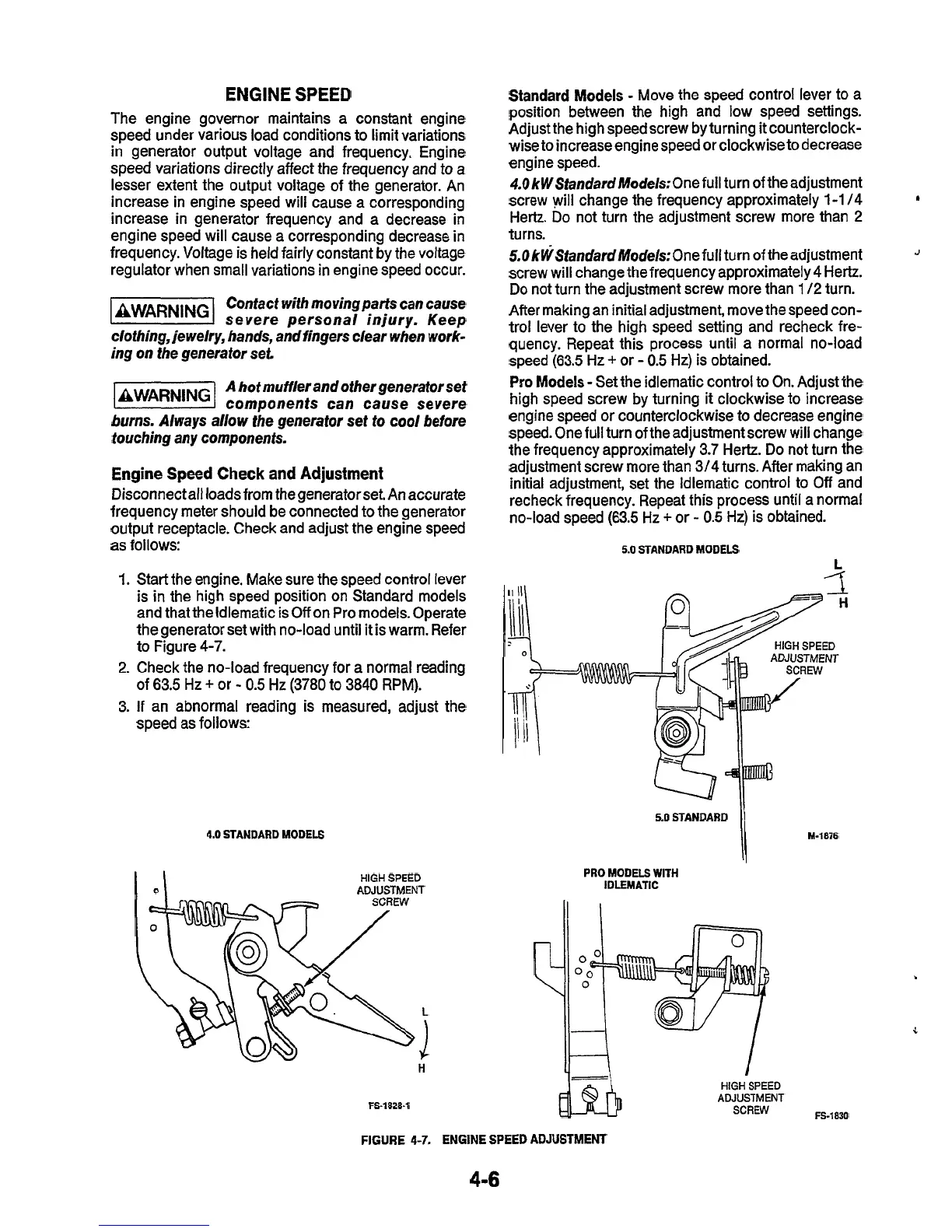

5.0

k

WSfandard Models:

One full turn of the adjustment

screw

will

change the frequency approximately4 Hertz.

Do

not turn the adjustment screw more than

112

turn.

After making an initial adjustment, move the speed con-

trol lever to the high speed setting and recheck fre-

quency. Repeat this process until a normal no-load

speed (63.5 Hz

+

or

-

0.5

Hz) is obtained.

Pro

Models

-

Set the idlematic control to On. Adjust the

high speed screw by turning

it

clockwise

to

increase

engine speed or counterclockwise to decrease engine

speed. One full turn of theadjustment screw

will

change

the frequency approximately 3.7 Hertz. Do not turn the

adjustment screw more than

314

turns. After making an

initial adjustment, set the Idlematic control

to

Off

and

recheck frequency. Repeat this process until a normal

no-load speed (63.5 Hz

+

or

-

0.5

Hz) is obtained.

6

J

5.0

STANDARD MODELS

L

PRO

MODELS

WITH

IDLEMATIC

M-1876

FS-1830

FIGURE

4-7.

ENGINE SPEED ADJUSTMENT

4-6

Loading...

Loading...