8-4

Fuel Pressure Regulator

The fuel pressure regulator body (Figure 8-2) is re-

moveable from the rail assembly by disconnecting

the vacuum hose and removing the circlip.

Apply light motor oil (sparingly) to the two O-ring

seals when reassembling.

The manifold vacuum hose is connected to the back

of the regulator diaphragm to maintain a constant

fuel pressure differential across the fuel injectors as

intake manifold pressure varies. Make sure to re-

connect the vacuum hose. Push the ends on dry all

the way up the hose barbs.

MAT Sensor

Check electrical resistance across the two terminals

of the MAT sensor (Figure 8-2). Replace the sensor

if resistance is not 2600 to 3000 ohms. To remove

the sensor, remove the throttle body (Page 8-1),

disconnect the wiring harness and unthread it from

the manifold.

When reinstalling the sensor apply Teflon thread

coating to the threads of the sensor. Turn it in until

just two threads are left.

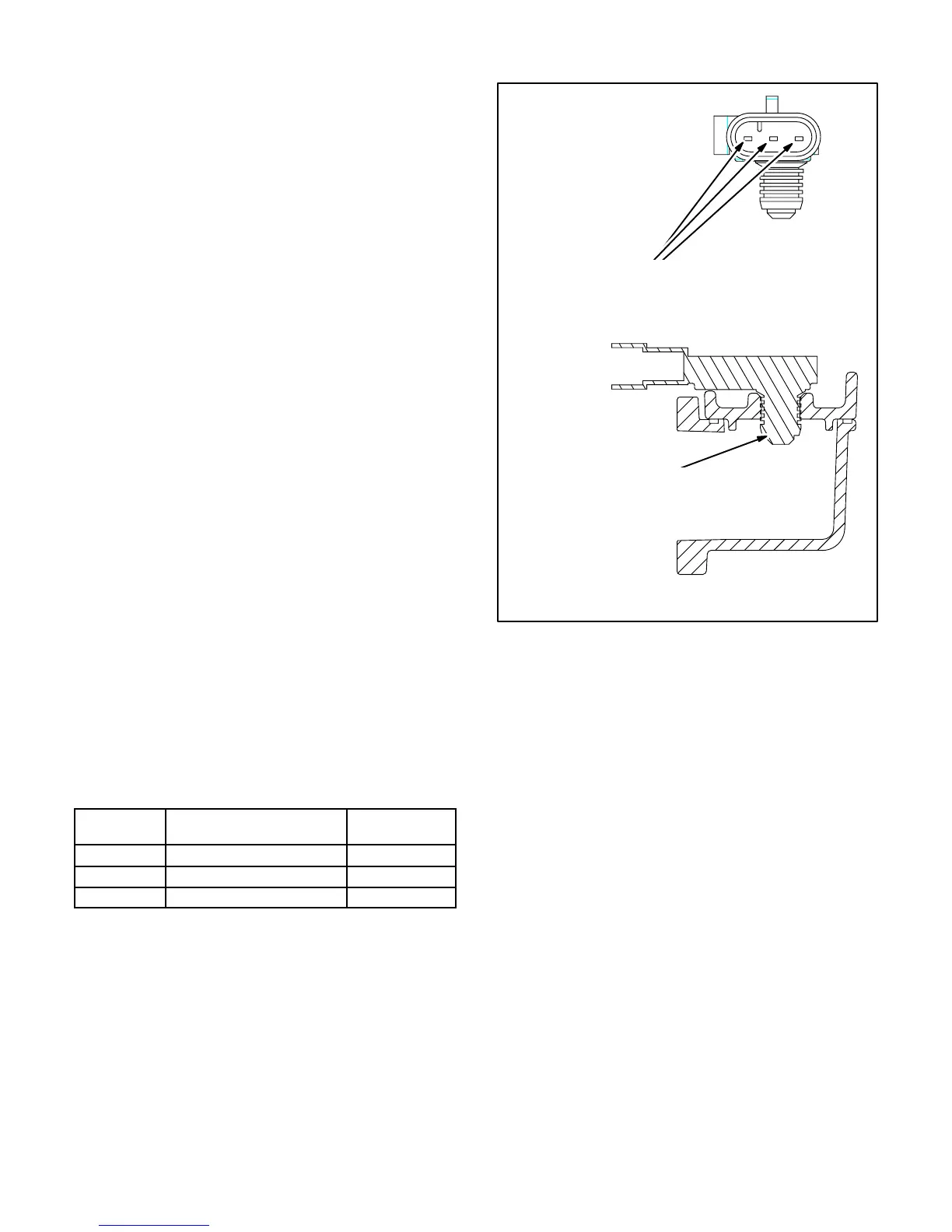

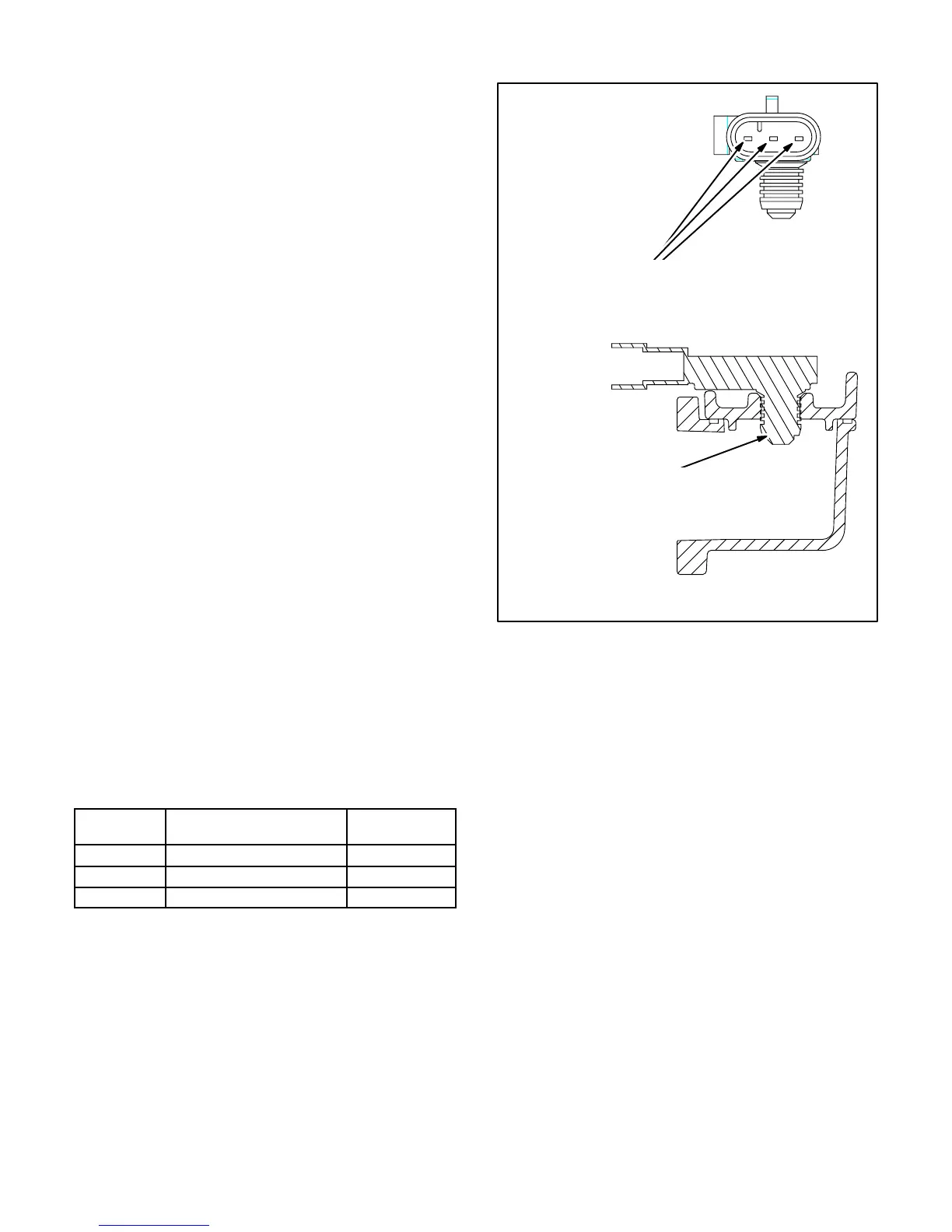

MAP Sensor

The genset enclosure must be removed to remove

the MAP sensor, which is pulled straight up to re-

move it from the intake manifold (Figure 8-2). To

check electrical resistances across the pins indi-

cated in Figure 8-3, remove the connector. To deter-

mine the letter designation of a pin, check the mark-

ing on the corresponding connector lead. Replace

the sensor if any reading is out of specification

(Table 8-2).

TABLE 8-2 MAP SENSOR RESISTANCES

PINS

KILO-OHMS @ Room

Temperature & Pressure

CONNECTION

A-C 4.0-4.2 GND-5V

A-B 91-101 GND-V

out

B-C 91-97 V

out

-5V

When reinstalling the sensor, apply light motor oil

(sparingly) to the the sealing grommet and push it in

by hand. Make sure the grommet is all the way

through the hole so that it will not come out (Fig-

ure 8-3).

MAKE SURE SEALING

GROMMET IS ALL THE

WAY THROUGH HOLE

CHECK ELECTRICAL RESISTANCES

ACROSS THESE TERMINALS

FIGURE 8-3. MAP SENSOR

Loading...

Loading...