8-19

MECHANICAL GOVERNOR—HGJAB,

HGJAC, HGJAE, HGJAF

The mechanical governor (Figure 8-18) operates

the throttle plate in the carburetor or mixer to main-

tain constant engine speed (within a range of 5 per-

cent) as load varies. See Page 9-14 regarding the

internal governor parts.

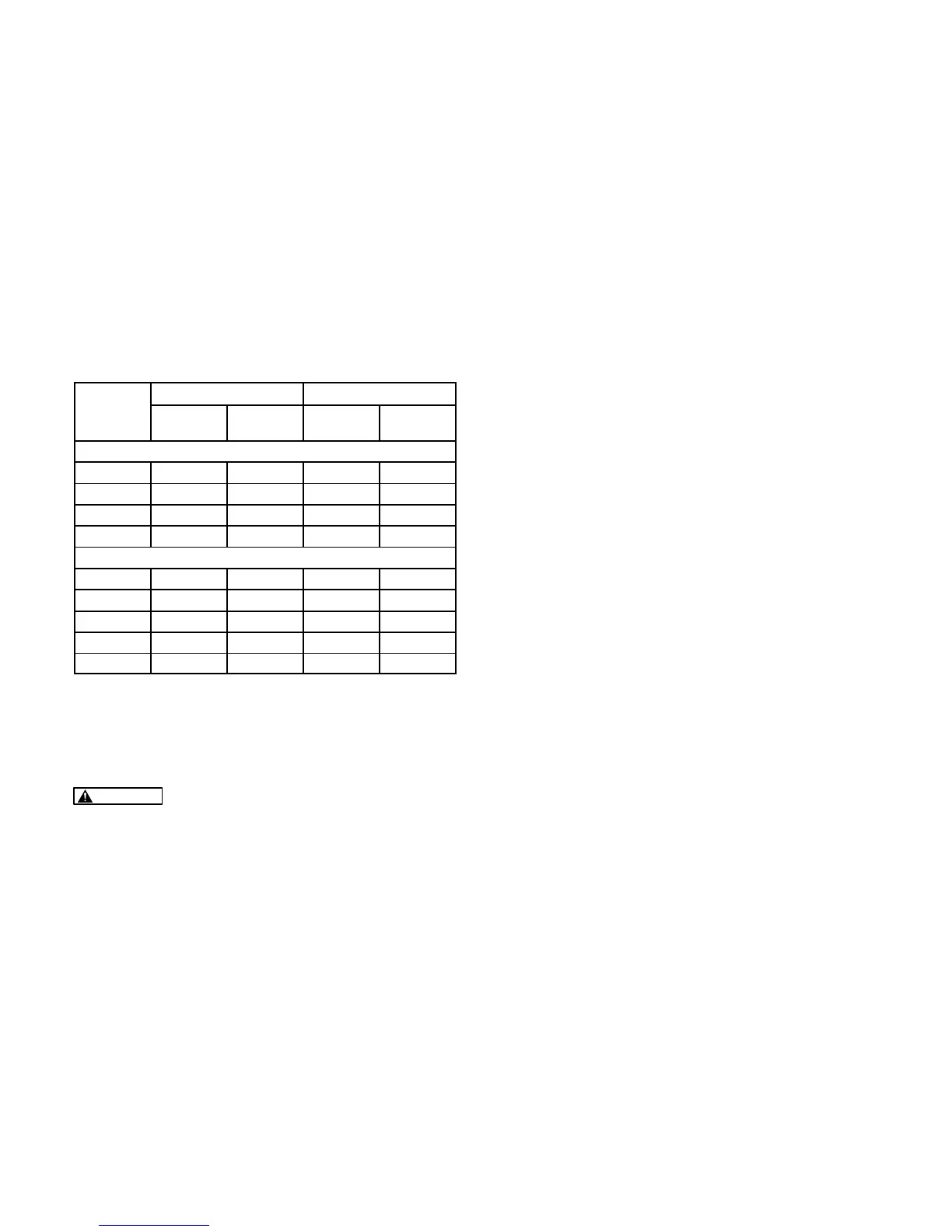

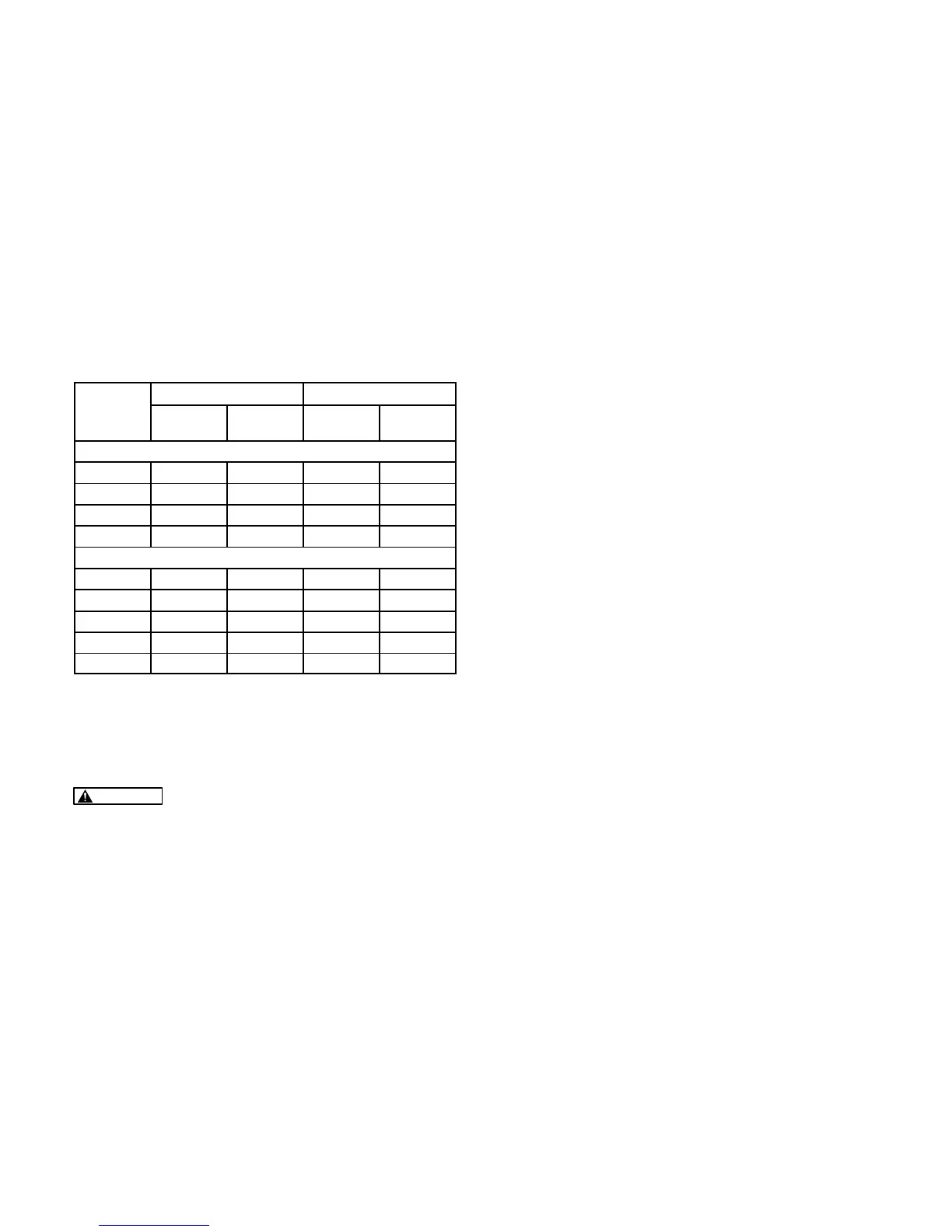

See Table 8-3 for rated voltage and frequency ver-

sus allowable voltage range and droop (the differ-

ence between No-Load frequency and Full-Load

frequency).

TABLE 8-3 VOLTAGE / FREQUENCY / DROOP

Voltage Frequency

ate

Voltage

Max No

Load

Min Full

Load

No Load Droop

60 HERTZ GENSETS

100 108 93 63/62 2–4

120 125 112 63/62 2–4

200 216 186 63/62 2–4

240 250 224 63/62 2–4

50 HERTZ GENSETS

100 108 93 52.5/51.5 2–4

200 216 186 52.5/51.5 2–4

220 238 205 52.5/51.5 2–4

230 249 215 52.5/51.5 2–4

240 250 224 52.5/51.5 2–4

Before making governor adjustments, check for oth-

er causes of hunting or excessive droop, such as

binding governor linkage, fouled spark plugs, im-

proper valve lash, and dirty fuel filters.

CAUTION

Voltage/frequency-sensitive equip-

ment such as VCRs, televisions, computers,

etc. may be damaged by power line frequency

variations. Some solid-state devices are pow-

ered whenever connected to an AC outlet even if

the device is not in actual operation. For this

reason, disconnect all devices which are volt-

age or frequency-sensitive before attempting

any carburetor/governor adjustments. If dis-

connecting the devices is not possible, open

the circuit breaker(s) at the distribution panel or

at the genset, if so equipped.

Accurate governor adjustments require a variable

load bank of up to 7 kW capacity and accurate me-

ters for measuring frequency (within 0.3%), voltage

(within 0.5%) and output current (AC).

Assembling Governor Linkage

Reassemble the throttle link and its tension spring if

they have not been assembled as shown in Fig-

ure 8-18. The easiest way is to hook both ends of

link and spring while the governor arm is detached.

Hook the tension spring below the throttle link in the

throttle lever so that it can pull down on the bottom of

the hole while the throttle link can push up on the top

of the hole without interfering with each other.

To detach the governor arm, remove the governor

shaft nut by turning it clockwise and then pull the

arm away from the shaft hub. To reattach the arm,

see Resetting Governor Arm.

Resetting Governor Arm

Anytime the carburetor or governor linkage has

been disturbed by disassembly and reassembly, it

will be necessary to reset the governor arm on the

governor shaft, as follows (see Figure 8-18):

1. Loosen the governor shaft nut by turning it

clockwise and remove the arm.

2. Use a battery terminal puller or equivalent tool

to break the taper fit of the shaft in the arm hub.

3. Reattach arm and hub, making sure the two

pins and holes engage, and thread the shaft nut

on counterclockwise. Check for free rotation

of the arm around the shaft and let the governor

spring take up all play in the linkage. The link-

age must push the throttle up against the wide

open throttle stop.

4. Torque the shaft nut to 8 lb-ft (11 N-m), coun-

terclockwise. (By design, tightening counter-

clockwise takes up play between the internal

governor parts.)

5. Gently push the governor arm down and check

for binding, rubbing against adjacent parts, in-

terference with wiring and looseness.

Adjusting Governor

Adjust the governor as follows (see Figure 8-18):

1. Warm up the genset for at least 5 minutes at 1/2

to 3/4 rated load. The choke must be complete-

ly open. Adjust frequency as close as possible

to the appropriate Table 8-3 value with the

speed adjusting nut to keep the genset from

shutting down (most likely on Fault 14—Over-

frequency or Fault 15—Underfrequency). Re-

start in 5 seconds if it shuts down.

Loading...

Loading...