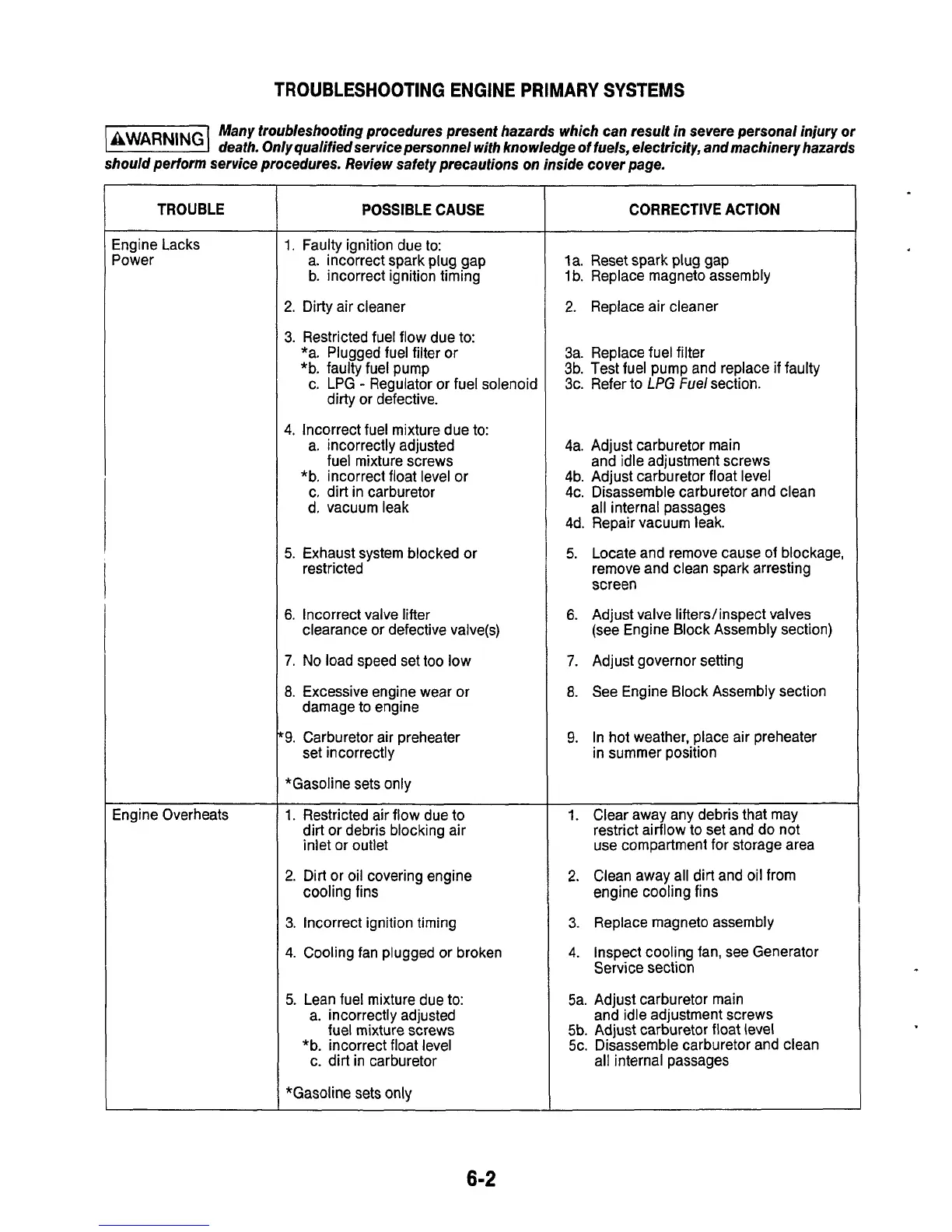

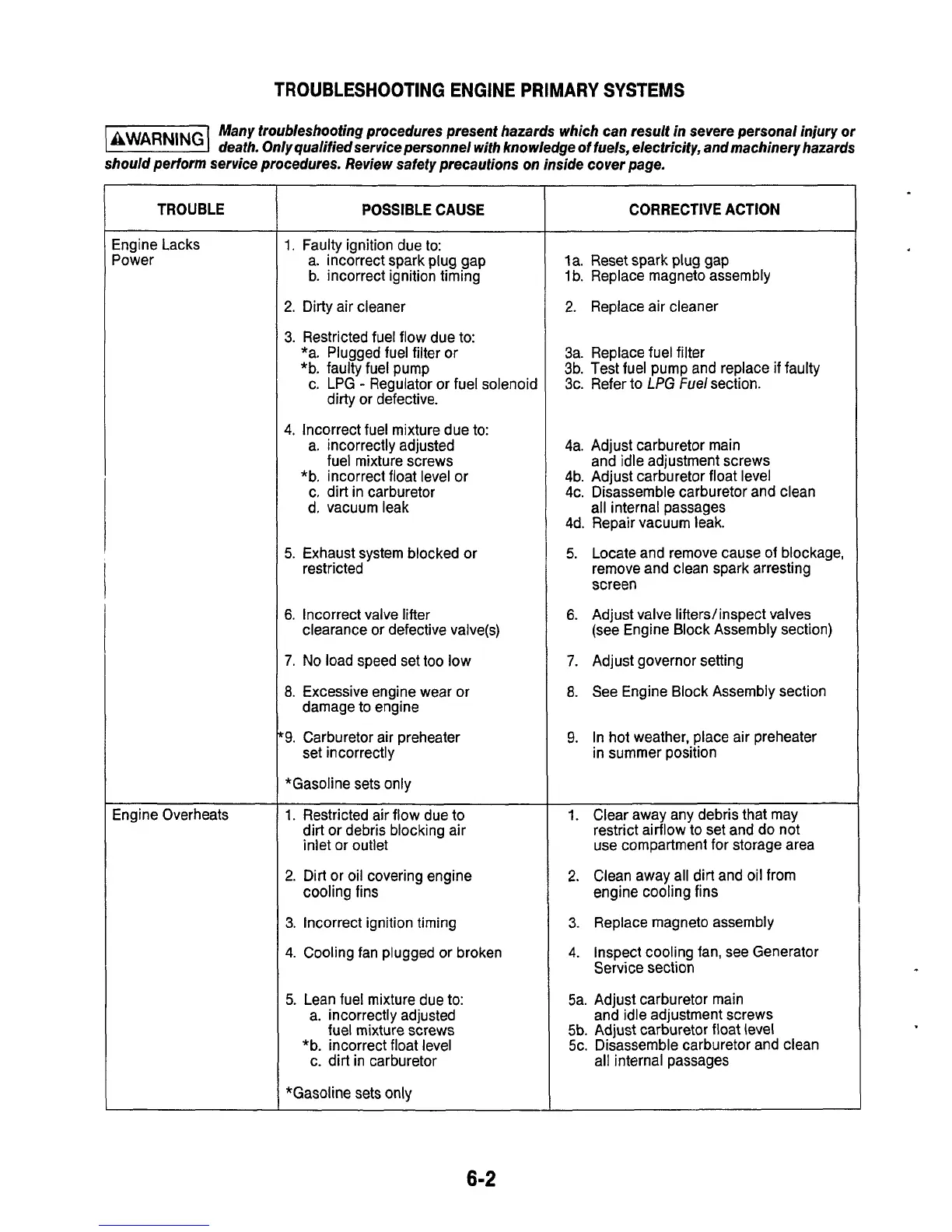

TROUBLESHOOTING ENGINE PRIMARY SYSTEMS

Many troubleshooting procedures present hazards which can result in severe personal injury

or

laWAR"Gl

death. Only qualifiedservice personnel with knowledge

of

fuels, electricity, andmachinery hazards

should perform service procedures. Review safety precautions

on

inside cover page.

Engine Lacks

Power

POSSIBLE

CAUSE

1.

Faulty ignition due

to:

a. incorrect spark plug gap

b. incorrect ignition timing

2.

Dirty air cleaner

3. Restricted fuel flow due

to:

*a. Plugged fuel filter or

*b. faulty fuel pump

dirty or defective.

4.

Incorrect fuel mixture due

to:

a. incorrectly adjusted

fuel mixture screws

*b. incorrect float level or

c. dirt in carburetor

d. vacuum leak

c.

LPG

-

Regulator or fuel solenoid

5.

Exhaust system blocked or

restricted

6.

Incorrect valve lifter

7.

No

load speed set

too

low

8.

Excessive engine wear or

damage to engine

9.

Carburetor air preheater

set incorrectly

*Gasoline sets only

1.

Restricted air flow due

to

dirt or debris blocking air

inlet or outlet

clearance or defective valve(s)

2.

Dirt or oil covering engine

3. Incorrect ignition timing

4.

Cooling fan plugged or broken

cooling fins

5.

Lean fuel mixture due to:

a. incorrectly adjusted

fuel mixture screws

*b. incorrect float level

c. dirt in carburetor

*Gasoline sets only

CORRECTIVE

ACTION

1

a. Reset spark plug gap

1

b. Replace magneto assembly

2.

Replace air cleaner

3a. Replace fuel filter

3b. Test fuel pump and replace if faulty

3c. Refer

to

LPG

Fuel section.

4a. Adjust carburetor main

and idle adjustment screws

4b. Adjust carburetor float level

4c. Disassemble carburetor and clean

all internal passages

4d. Repair vacuum leak.

5.

Locate and remove cause of blockage,

remove and clean spark arresting

screen

6.

Adjust valve lifters/inspect valves

(see Engine Block Assembly section)

7.

Adjust governor setting

8.

See Engine Block Assembly section

9.

In hot weather, place air preheater

in summer position

1.

Clear away any debris that may

restrict airflow to set and do not

use compartment for storage area

2.

Clean away all dirt and oil from

engine cooling

fins

3.

Replace magneto assembly

4.

Inspect cooling fan, see Generator

Service section

5a. Adjust carburetor main

and idle adjustment screws

5b.

Adjust

carburetor float level

5c. Disassemble carburetor and clean

all internal passages

Loading...

Loading...