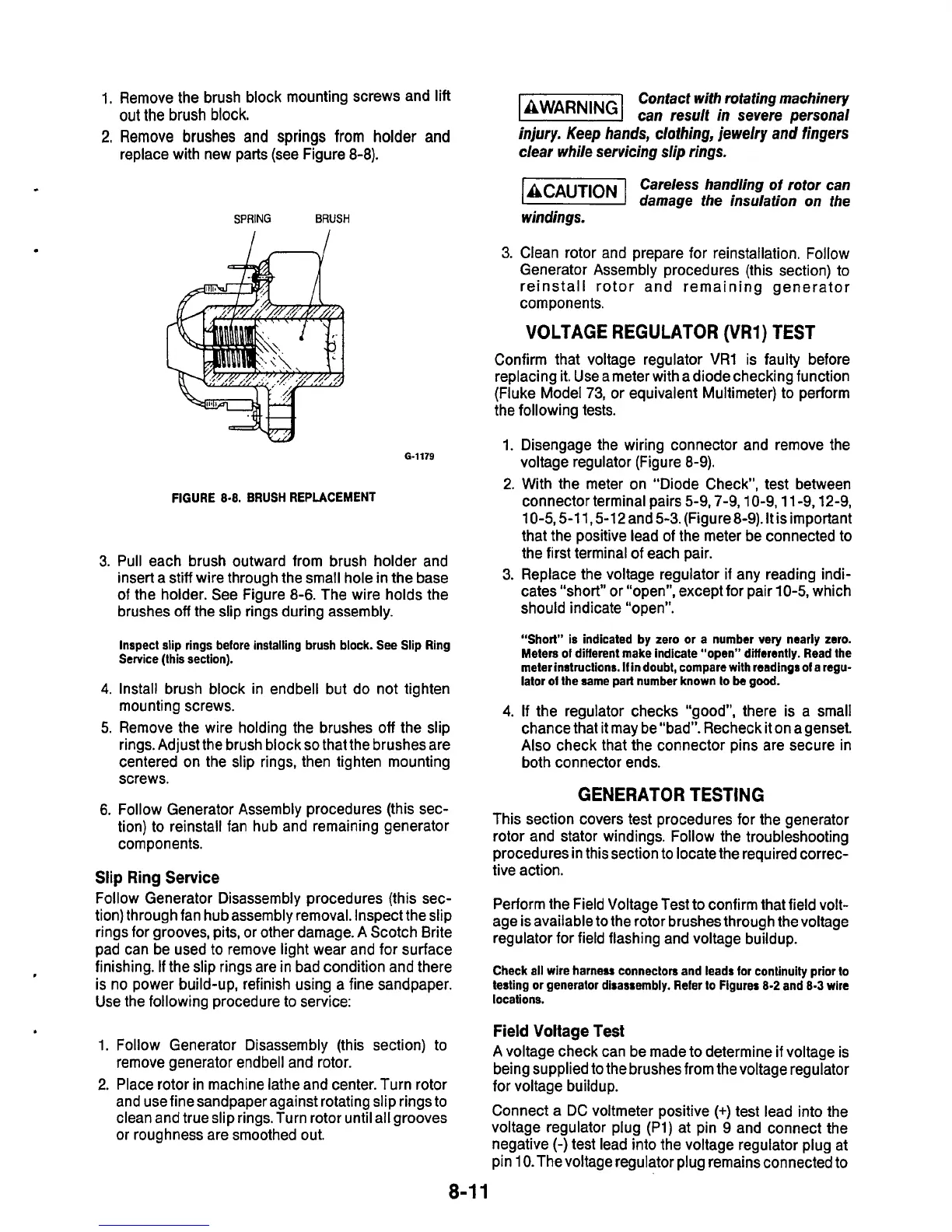

1.

Remove the brush block mounting screws and

lift

2.

Remove

brushes

and

springs from holder and

out the brush block.

replace with new parts (see Figure 8-8).

SPRING

BRUSH

I

6-1179

FIGURE

8-8.

BRUSH

REPLACEMENT

3.

Pull each brush outward from brush holder and

insert a stiff wire through the small hole in the base

of the holder. See Figure

8-6.

The wire holds the

brushes

off

the slip rings during assembly.

Confact with rotating machinery

llEEE%l

can

result

in

severe

personal

injury.

Keep

hands,

cloihing,

jewelry

and

fingers

clear

while

servicing slip rings.

ACAUT~ON

Careless handling

of

rotor

can

D

damage the insulation on the

windings.

3.

Clean rotor and prepare for reinstallation. Follow

Generator Assembly procedures (this section) to

reinstall rotor and remaining generator

components.

VOLTAGE REGULATOR

(VR1)

TEST

Confirm that voltage regulator VR1 is faulty before

replacing it. Use a meter with adiodechecking function

(Fluke Model

73,

or equivalent Multimeter) to perform

the following tests.

1. Disengage the wiring connector and remove the

voltage regulator (Figure 8-9).

2.

With the meter on “Diode Check”, test between

connector terminal pairs 5-9,7-9.10-9,11-9,12-9,

10-5,5-11 5-12 and

5-3.

(Figure8-9).

It

is important

that the positive lead of the meter be connected to

the first terminal of each pair.

3.

Replace the voltage regulator

if

any reading indi-

cates “short” or “open”. except for pair

10-5,

which

should indicate “open”.

,

Inspect slip rings before installing brush block.

See

Slip Ring

Service (this section).

4.

Install brush block in endbell but do not tighten

mounting screws.

5.

Remove the wire holding the brushes

off

the slip

rings. Adjust the brush block

so

that the brushes are

centered on the slip rings, then tighten mounting

screws.

6.

Follow Generator Assembly procedures (this sec-

tion) to reinstall fan hub and remaining generator

components.

Slip

Ring

Service

Follow Generator Disassembly procedures (this sec-

tion) through fan hub assembly removal. Inspect the slip

rings for grooves, pits, or other damage. A Scotch Brite

pad can be used

to

remove light wear and for surface

finishing.

If

the slip rings are in bad condition and there

is no power build-up, refinish using a fine sandpaper.

Use the following procedure

to

service:

“Short” is indicated by zero or a number very nearly zero.

Meters

of

diflerent make indicate “open” differently. Read the

meter instructions.

If

in doubt, compare with readings

of

a regu-

lator

of

the same part number known to

be

good.

4.

If the regulator checks “good”, there is a small

chance that it may be”bad”. Recheck it on agenset.

Also

check that the connector pins are secure in

both connector ends.

GENERATOR TESTING

This section covers test procedures for the generator

rotor and stator windings. Follow the troubleshooting

procedures in this section

to

locate the required correc-

tive action.

Perform the Field Voltage Test to confirm that field volt-

age is available to the rotor brushes through the voltage

regulator for field flashing and voltage buildup.

Check all wire harness connectors and leads

for

continuity

prior

to

testing

or

generator disassembly. Refer to Figurer

8-2

and

8-3

wire

locations.

1.

2.

Field

Voltage Test

being supplied to the brushes from the voltage regulator

for voltaae builduD.

Follow Generator Disassembly (this section) to

A voltage check can be made to determine

if

voltage is

remove generator endbell and rotor.

Place rotor in machine lathe and center. Turn rotor

I

Connect a DC voltmeter positive

(+)

test lead into the

voltage regulator plug

(Pl)

at pin

9

and connect the

negative (-)test lead into the voltage regulator plug at

pin

10.

The voltage regulator plug remains connected to

and use fine sandpaper against rotating slip rings to

clean and true slip rings. Turn rotor until all grooves

or roughness are smoothed out.

8-1

1

Loading...

Loading...