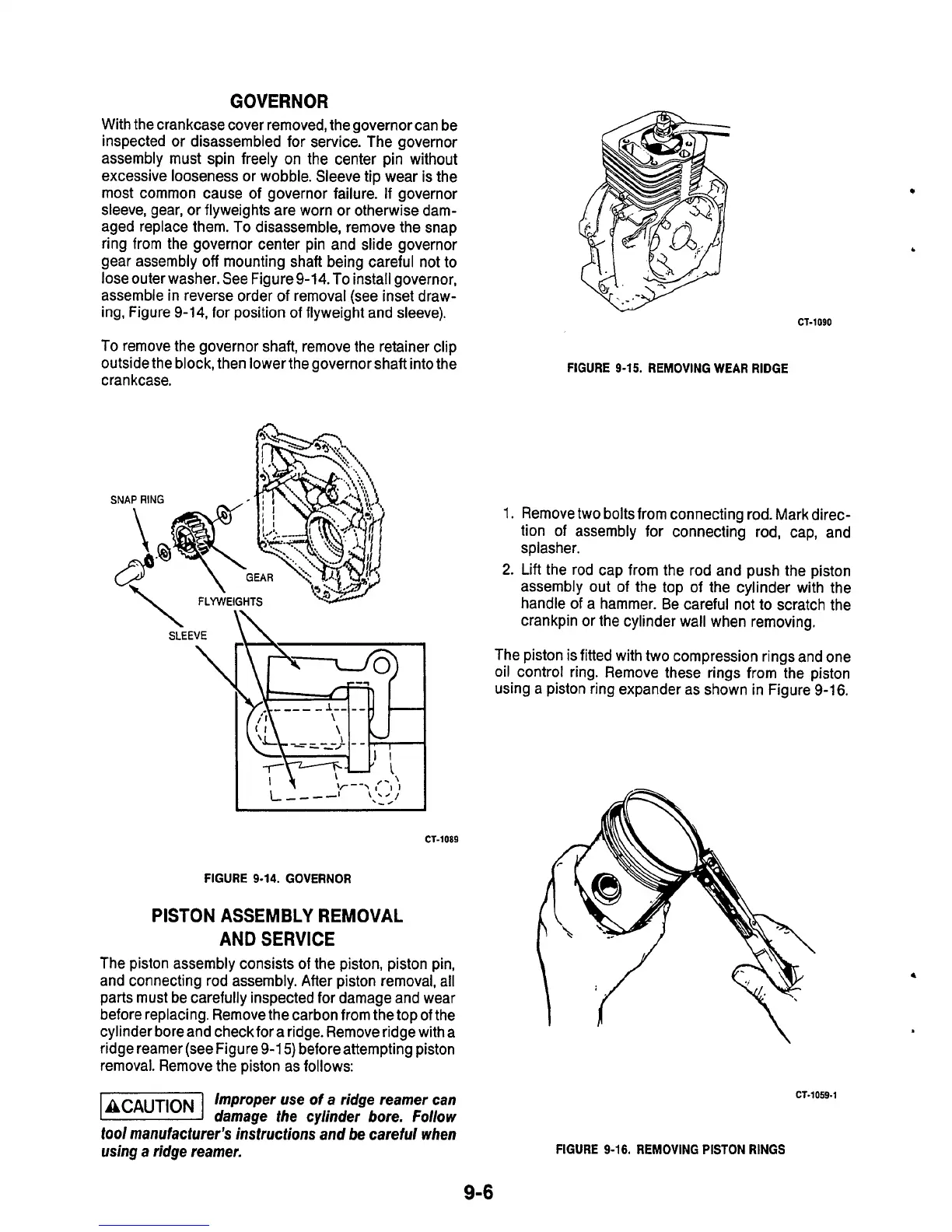

GOVERNOR

With the crankcase cover removed, the governor can be

inspected or disassembled for service. The governor

assembly must spin freely on the center pin without

excessive looseness or wobble. Sleeve tip wear is the

most

common cause of governor failure.

If

governor

sleeve, gear, or flyweights are worn or otherwise dam-

aged replace them. To disassemble, remove the snap

ring from the governor center pin and slide governor

gear assembly

off

mounting shaft being careful not

to

lose outer washer. See Figure9-14. To install governor,

assemble in reverse order of removal (see inset draw-

ing, Figure 9-14, for position of flyweight and sleeve).

v

CT-1090

To remove the governor shaft, remove the retainer clip

outside the block, then lower the governor shaft into the

crankcase.

FIGURE

9-15.

REMOVING

WEAR

RIDGE

1. Remove two bolts from connecting rod. Mark direc-

tion of assembly for connecting rod, cap, and

splasher.

2.

Lift the rod cap from the rod and push the piston

assembly out of the top

of

the cylinder with the

handle of a hammer. Be careful not

to

scratch the

crankpin or the cylinder wall when removing.

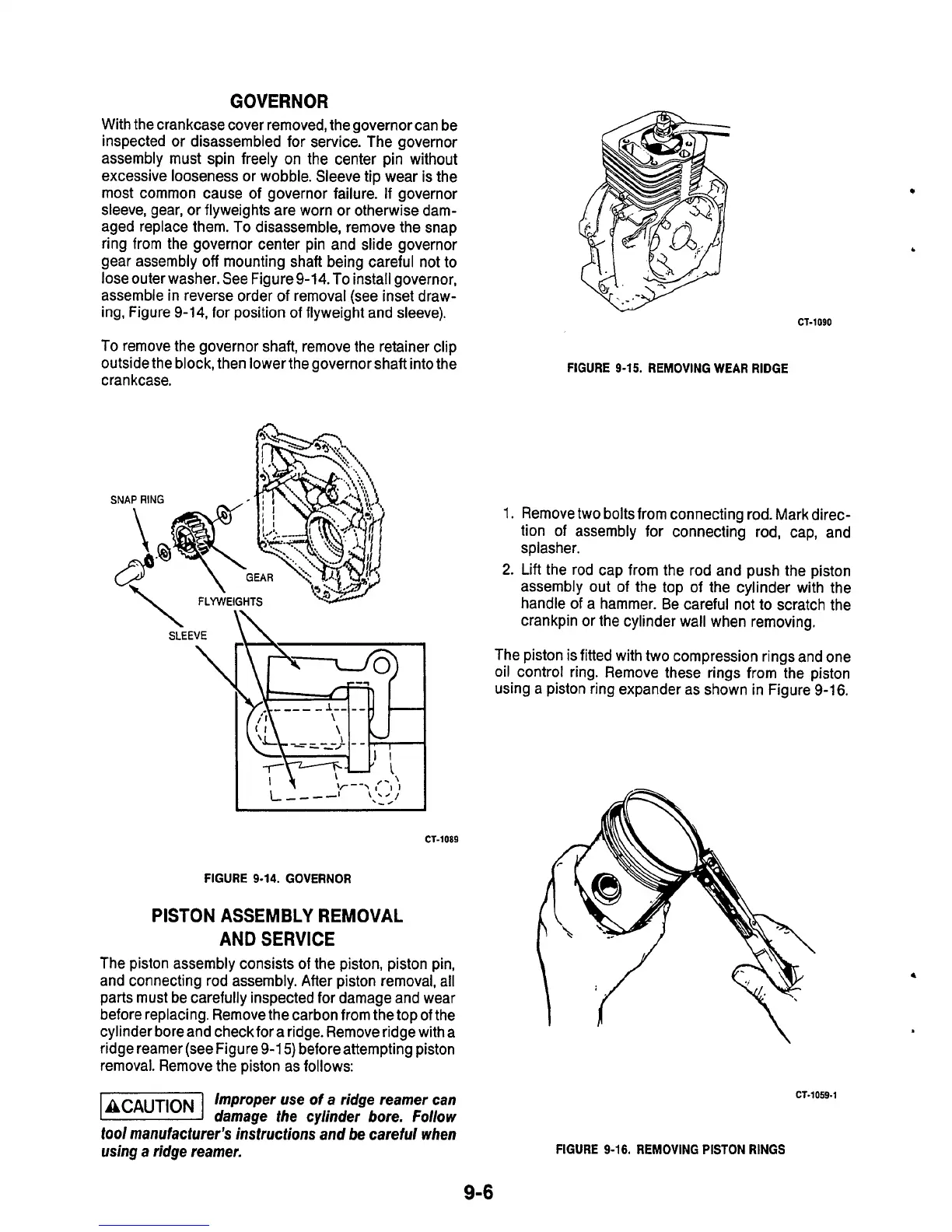

The piston

is

fitted with two compression rings and one

oil control ring. Remove these rings from the piston

using a piston ring expander as shown in Figure 9-16.

\

\\

CT-1089

FIGURE

9-14.

GOVERNOR

PISTON ASSEMBLY REMOVAL

AND SERVICE

The piston assembly consists of the piston, piston pin,

and connecting rod assembly. After piston removal, all

parts must be carefully inspected for damage and wear

before replacing. Remove the carbon from the top of the

cylinder bore and check for a ridge. Remove ridge with a

ridge reamer (see Figure 9-1

5)

before attempting piston

removal. Remove the piston as follows:

-1

Improper use

of

a

ridge reamer can

damage

fhe

cylinder bore. Follow

fool

manufacfurer's instructions and be careful when

using a ridge reamer.

CT-1059-1

FIGURE

9-16.

REMOVING PISTON

RINGS

9-6

Loading...

Loading...