0

Splash Fouled

-

Check for accumulated combus-

tion chamber deposits. See Cylinder Head section.

0

Light Tan or Gray Deposits

-

Normal plug color.

If

the spark

plug

is in good condition,

proceed

to

the Ignition

Coil section.

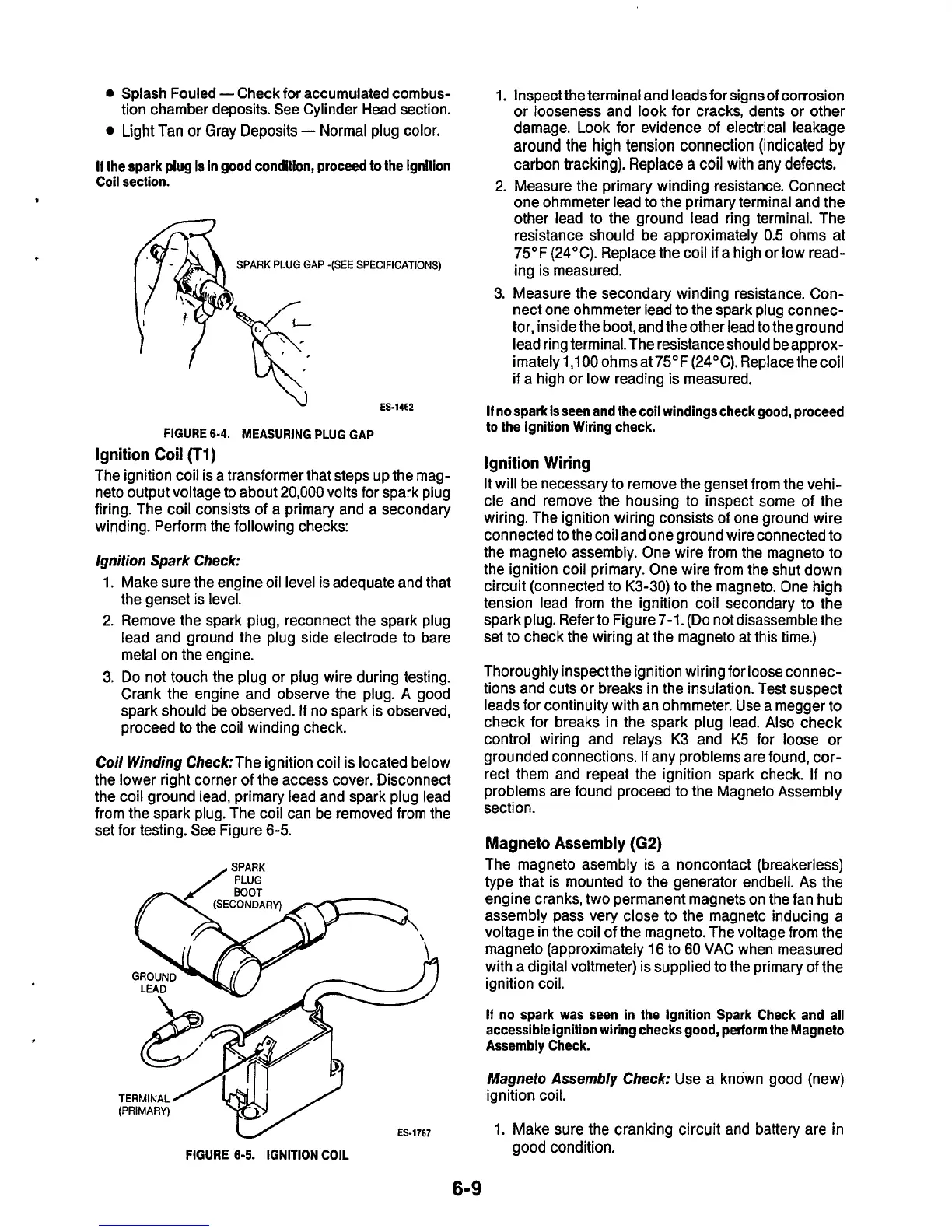

SPARK

PLUG

GAP

-(SEE

SPECIFICATIONS)

ES-1462

FIGURE

6-4.

MEASURING PLUG GAP

Ignition Coil

(TI)

The ignition coil is a transformer that steps up the mag-

neto output voltage to about

20,000

volts for spark plug

firing. The coil consists of a primary and a secondary

winding. Perform the following checks:

Ignition

Spark Check:

1.

Make sure the engine oil level is adequate and that

the genset

is

level.

2.

Remove the spark plug, reconnect the spark plug

lead and ground the plug side electrode to bare

metal on the engine.

3.

Do

not touch the plug or plug wire during testing.

Crank the engine and observe the plug. A good

spark should be observed.

If

no spark is observed,

proceed to the coil winding check.

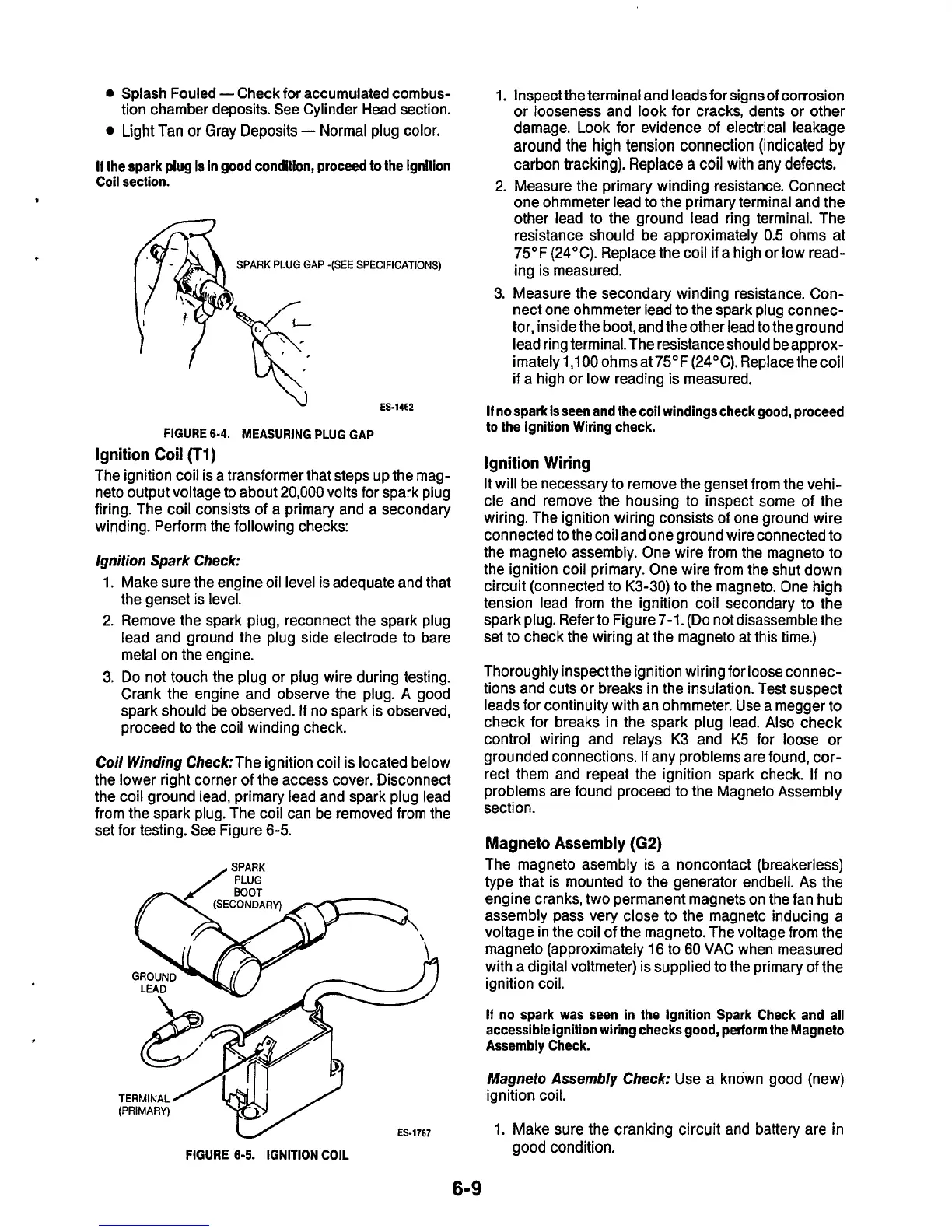

Coil

Winding

Check:The ignition coil is located below

the lower right corner

of

the access cover. Disconnect

the coil ground lead, primary lead and spark plug lead

from the spark plug. The coil can be removed from the

set for testing. See Figure

6-5.

SPARK

rwti

BOOT

.

TERMINAL/

1

(PRIMARY)

1.

2.

3.

Inspect the terminal and leadsfor signs

of

corrosion

or

looseness and look for cracks, dents or other

damage. Look for evidence

of

electrical leakage

around

the high

tension

connection (indicated

by

carbon tracking). Replace

a

coil with any defects.

Measure the primary winding resistance. Connect

one ohmmeter lead

to

the primary terminal and the

other lead to the ground lead ring terminal. The

resistance should be approximately

0.5

ohms at

75OF (24°C). Replace the coil if a high or low read-

ing

is

measured.

Measure the secondary winding resistance. Con-

nect one ohmmeter lead to the spark plug connec-

tor, inside the boot,and the other lead to the ground

lead ring terminal. The resistance should be approx-

imately 1,1000hmsat75°F(240C). Replacethecoil

if

a high or low reading is measured.

If

nospark

is

seen and the coil windings check good, proceed

to

the Ignition Wiring check.

ignition Wiring

It will be necessary to remove the genset from the vehi-

cle and remove the housing to inspect some of the

wiring. The ignition wiring consists of one ground wire

connected to the coil and one ground wire connected to

the magneto assembly. One wire from the magneto to

the ignition coil primary. One wire from the shut down

circuit (connected to

K3-30)

to the magneto. One high

tension lead from the ignition coil secondary to the

spark plug. Refer to Figure 7-1.

(Do

not disassemble the

set to check the wiring at the magneto at this time.)

Thoroughly inspect the ignition wiring for loose connec-

tions and cuts or breaks in the insulation. Test suspect

leads for continuity with an ohmmeter. Use a megger

to

check for breaks in the spark plug lead. Also check

control wiring and relays K3 and

K5

for loose

or

grounded connections.

If

any problems are found, cor-

rect them and repeat the ignition spark check.

If

no

problems are found proceed to the Magneto Assembly

section.

Magneto Assembly

(G2)

The magneto asembly is a noncontact (breakerless)

type that is mounted

to

the generator endbell. As the

engine cranks, two permanent magnets on the fan hub

assembly pass very close to the magneto inducing a

voltage in the coil of the magneto. The voltage from the

magneto (approximately

16

to

60

VAC when measured

with a digital voltmeter) is supplied to the primary of the

ignition coil.

If

no spark

was

seen in the Ignition Spark Check and all

accessible ignition wiring checks good, perform the Magneto

Assembly Check.

Magneto

Assembly Check: Use a known good (new)

ignition coil.

W

ES-1767

FIGURE

6-5.

IGNITION

COIL

1.

Make sure the cranking circuit and battery are in

good condition.

6-9

Loading...

Loading...