TORQUETO

5-10

IN-LBS

(57

-

1.13

Nom)

RQUE TO

25-30

IN-LBS

(2.8

-

3.4

Nom)

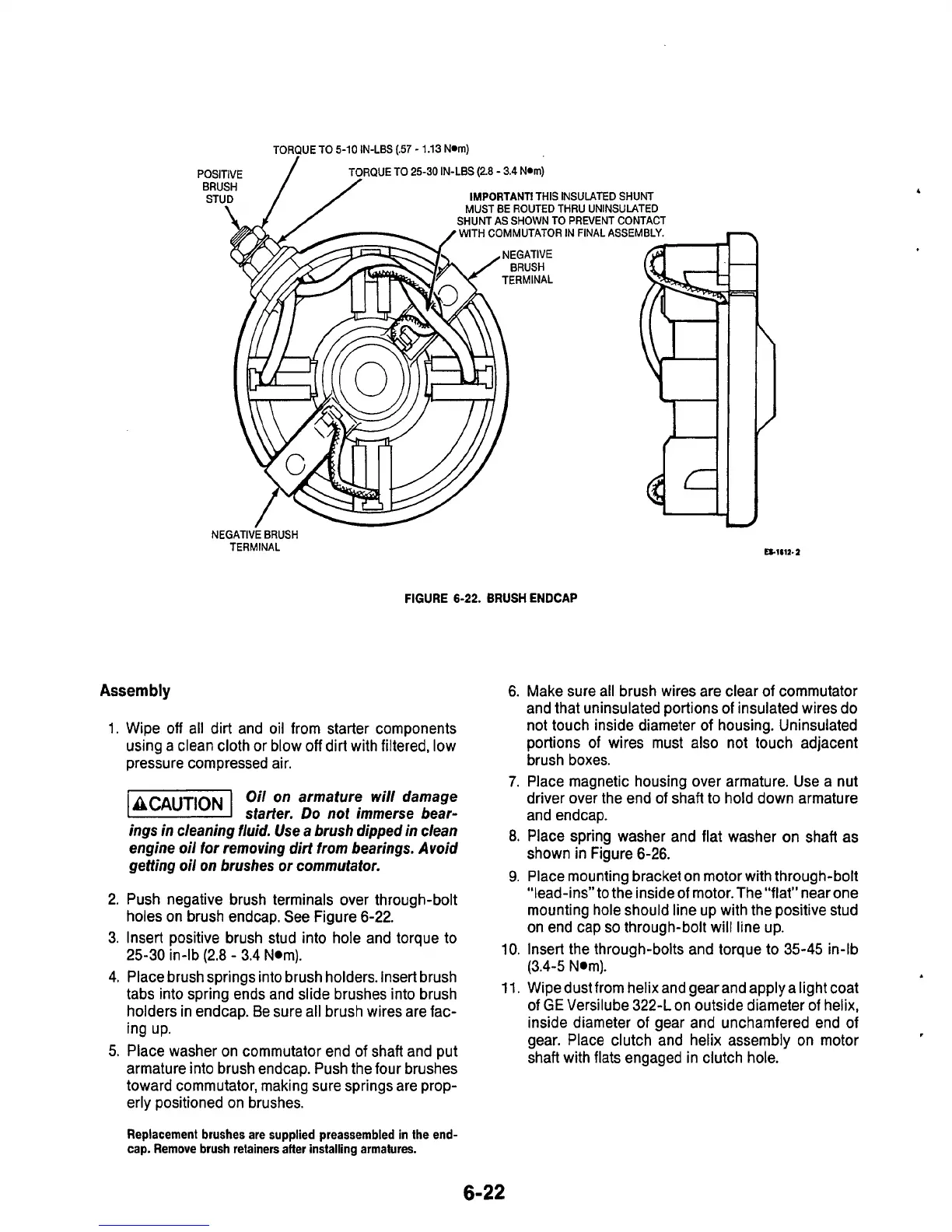

IMPORTANTI THIS

INSULATED

SHUNT

MUST

BE

ROUTED

THRU

UNINSULATED

SHUNT

AS

SHOWN

TO

PRNENT

WITH

COMMUTATOR

IN

FINAL

A

NEGATIVE

BRUSH

__

TERM~NAC

ES-16ll.2

FIGURE

6-22.

BRUSH

ENDCAP

Assembly

6.

Make sure all brush wires are clear

of

commutator

1.

2.

3.

4.

5.

Wipe

off

all dirt and oil from starter components

using a clean cloth or blow

off

dirt with filtered, low

pressure compressed air.

71

Oil

on

armature will damage

*CAUT’oN

starter.

Do

not immerse bear-

ings in cleaning fluid. Use a brush dipped in clean

engine oil

for

removing dirt from bearings. Avoid

getting oil on brushes

or

commutator.

Push negative brush terminals over through-bolt

holes on brush endcap. See Figure 6-22.

Insert positive brush stud into hole and torque to

25-30 in-lb (2.8

-

3.4 Nom).

Place brush springs into brush holders. Insert brush

tabs into spring ends and slide brushes into brush

holders in endcap. Be sure all brush wires are fac-

ing up.

Place washer on commutator end

of

shaft and put

armature into brush endcap. Push the four brushes

toward commutator, making sure springs are prop-

erly positioned on brushes.

Replacement brushes are supplied preassernbled in the end-

cap. Remove brush retainers alter installing armatures.

and that uninsulated portions of insulated wires do

not touch inside diameter

of

housing. Uninsulated

portions of wires must also not touch adjacent

brush boxes.

7.

Place magnetic housing over armature. Use a nut

driver over the end of shaft

to

hold down armature

and endcap.

8.

Place spring washer and flat washer on shaft as

shown in Figure 6-26.

9.

Place mounting bracket on motor with through-bolt

“lead-ins” to the inside of motor.The “flat” near one

mounting hole should line up with the positive stud

on end cap

so

through-bolt will line up.

10.

Insert the through-bolts and torque to 35-45 in-lb

(3.4-5 Nom).

11.

Wipedustfrom

helixandgearandapplyalight

coat

of

GE

Versilube 322-L on outside diameter of helix,

inside diameter of gear and unchamfered end of

gear. Place clutch and helix assembly on motor

shaft with flats engaged in clutch hole.

Loading...

Loading...