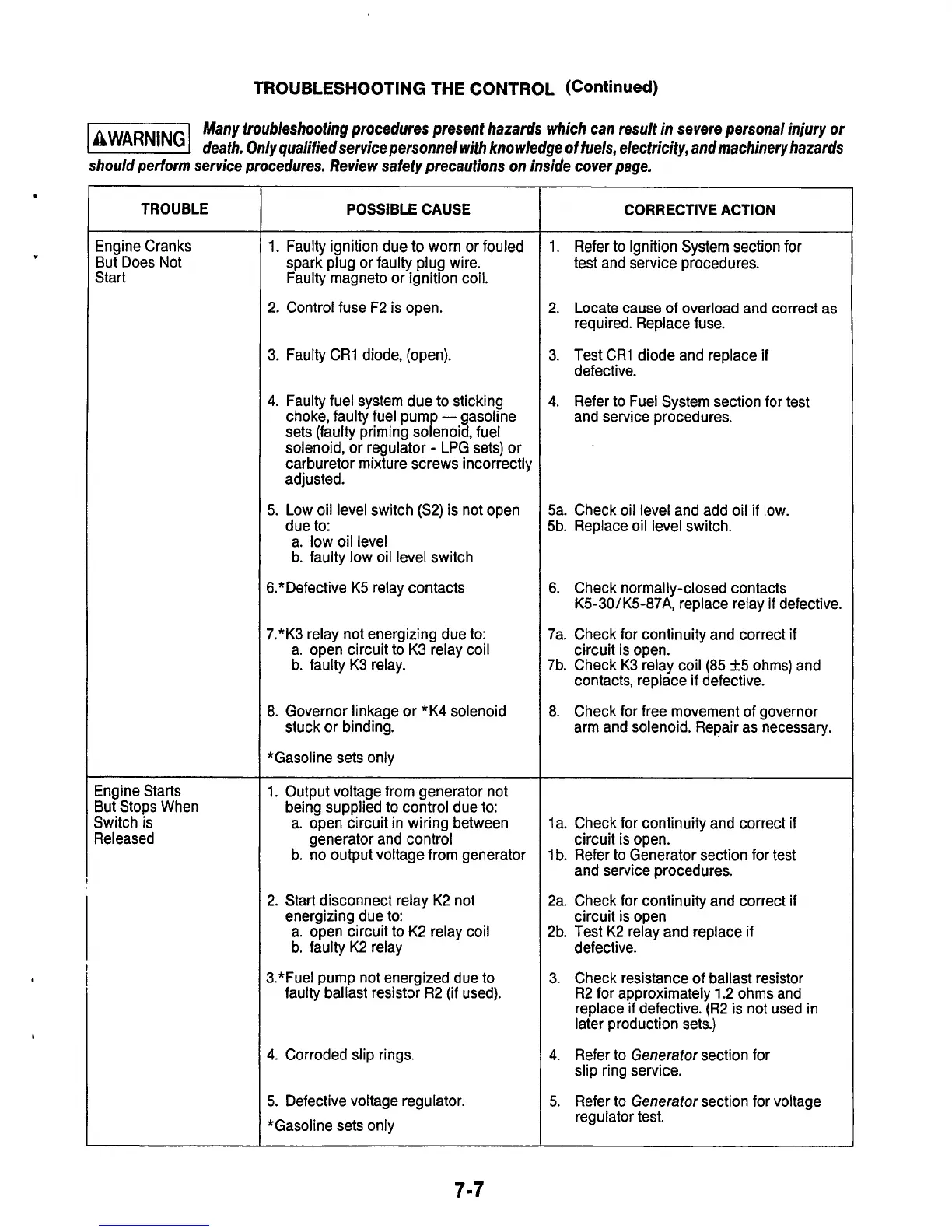

TROUBLESHOOTING THE CONTROL

(Continued)

*

Many troubleshooting procedures present hazards which can result in severe personal injury or

IBWAR"G/

death. Only qualified service personnel with knowledge

of

fuels, electricity, and machinery hazards

should perform service procedures. Review safely precautions on inside cover page.

TROUBLE

Engine Cranks

But Does Not

Start

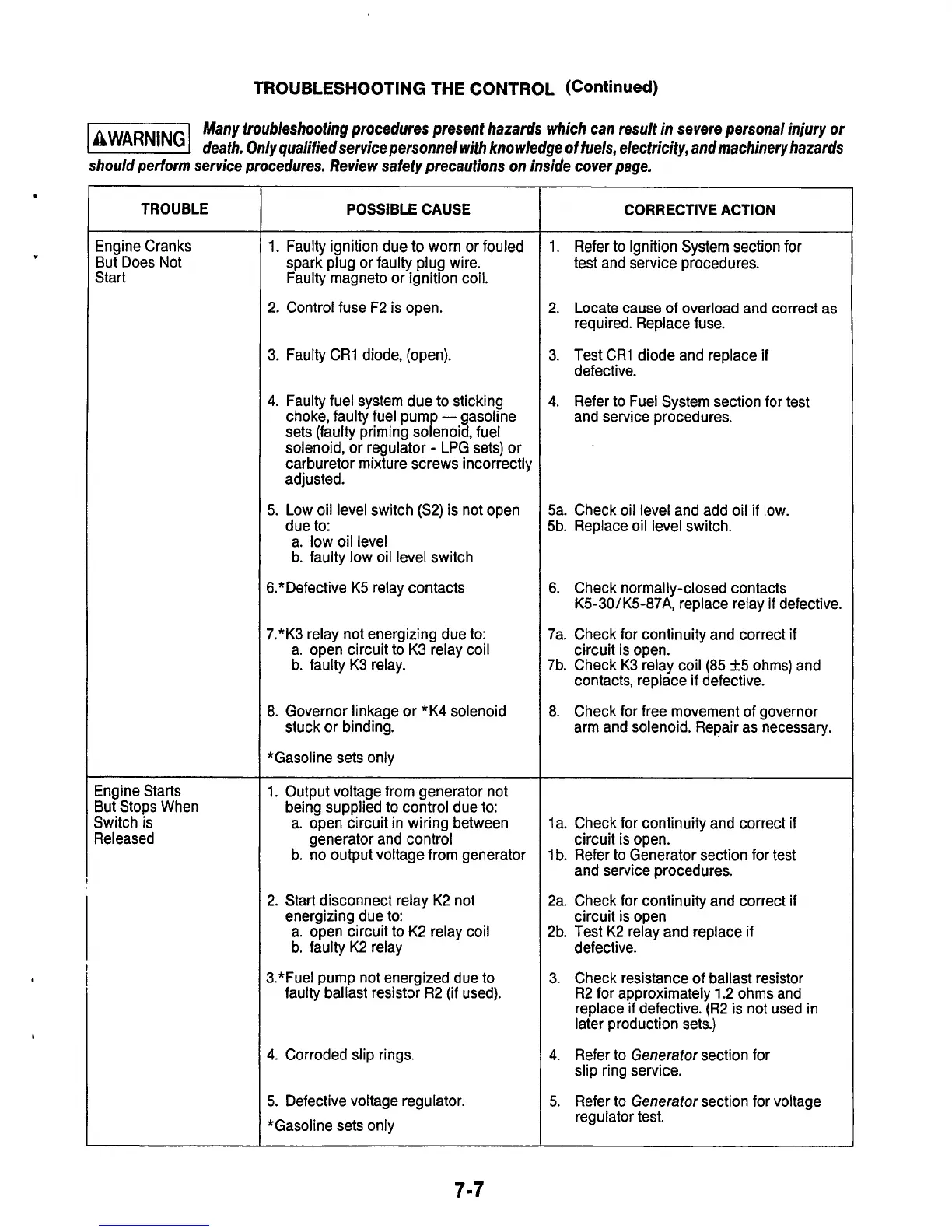

Engine Starts

But Stops When

Switch is

Released

POSSIBLE

CAUSE

1.

Faulty ignition due to worn

or

fouled

spark plug or faulty plug wire.

Faulty magneto or ignition coil.

2.

Control fuse F2 is open.

3.

Faulty CR1 diode, (open).

4.

Faulty fuel system due to sticking

choke, faulty fuel pump

-

gasoline

sets (faulty priming solenoid, fuel

solenoid, or regulator

-

LPG sets) or

carburetor mixture screws incorrectly

adjusted.

due to:

a. low oil level

b. faulty low oil level switch

5.

Low oil level switch (S2) is not open

6.*Defective K5 relay contacts

7.*K3 relay not energizing due to:

a. open circuit to K3 relay coil

b.

faulty

K3

relay.

8.

Governor linkage or

*K4

solenoid

stuck or binding.

*Gasoline sets only

1.

Output voltage from generator not

being supplied to control due to:

a. open circuit in wiring between

b.

no output voltage from generator

generator and control

2.

Start disconnect relay K2 not

energizing due to:

a. open circuit to

K2

relay coil

b. faulty K2 relay

3.*Fuel pump not energized due to

faulty ballast resistor R2 (if used).

4.

Corroded slip rings.

5.

Defective voltage regulator.

"Gasoline sets only

CORRECTIVE ACTION

1.

Refer

to

Ignition System section for

test and service procedures.

2.

Locate cause

of

overload and correct as

required. Replace fuse.

3. Test

CRl

diode and replace if

defective.

4.

Refer to Fuel System section for test

and service procedures.

5a. Check oil level and add oil

if

low.

5b. Replace oil level switch.

6.

Check normally-closed contacts

K5-30/ K5-87A, replace relay if defective.

7a. Check for continuity and correct

if

circuit is open.

7b. Check

K3

relay coil

(85

f5

ohms) and

contacts, replace

if

defective.

8.

Check for free movement of governor

arm and solenoid. Repair as necessary.

la. Check for continuity and correct

if

circuit is open.

1

b.

Refer to Generator section for test

and service procedures.

2a. Check for continuity and correct

if

circuit

is

open

2b.

Test K2 relay and replace

if

defective.

3. Check resistance of ballast resistor

R2 for approximately 1.2 ohms and

replace

if

defective. (R2

is

not used in

later production sets.)

4.

Refer to

Generator

section for

slip ring service.

5.

Refer to

Generator

section for voltage

regulator test.

7-7

Loading...

Loading...