Stems

and

Guides:Always check stems and guides for

wear as shown in Figure

9-6.

Use a hole gauge to

measure the valve guide. When clearance with stem

exceeds original clearance by

0.002

inch

(0.05

mm),

replace the valve or cylinder head, which includes the

valve guide, or both.

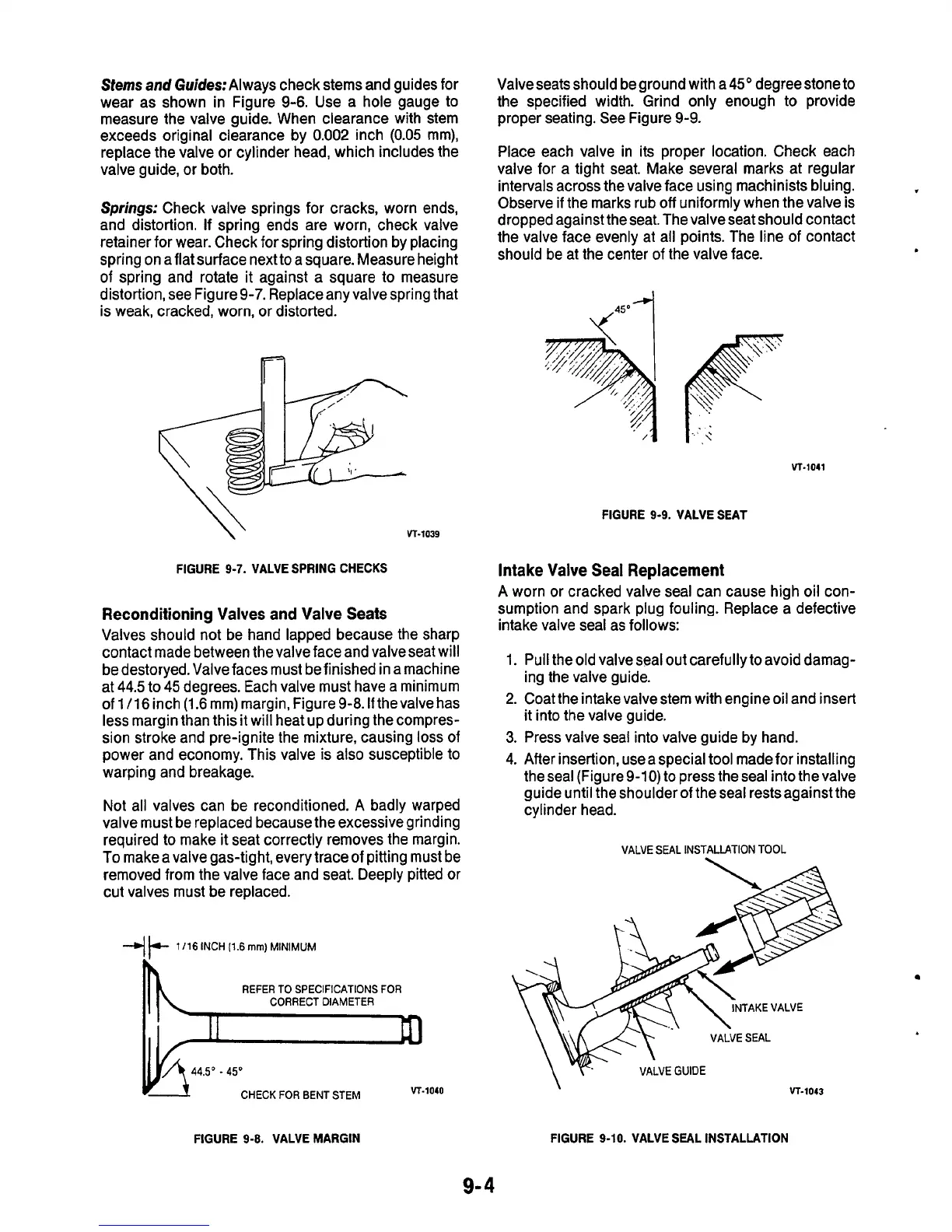

Springs:

Check valve springs for cracks, worn ends,

and distortion. If spring ends are worn, check valve

retainer for wear. Check for spring distortion by placing

spring on aflat surface nextto a square. Measure height

of spring and rotate it against a square to measure

distortion, see Figure

9-7.

Replace any valve spring that

is weak, cracked, worn, or distorted.

\'

VI-1039

FIGURE 9-7. VALVE SPRING CHECKS

Reconditioning

Valves

and

Valve Seats

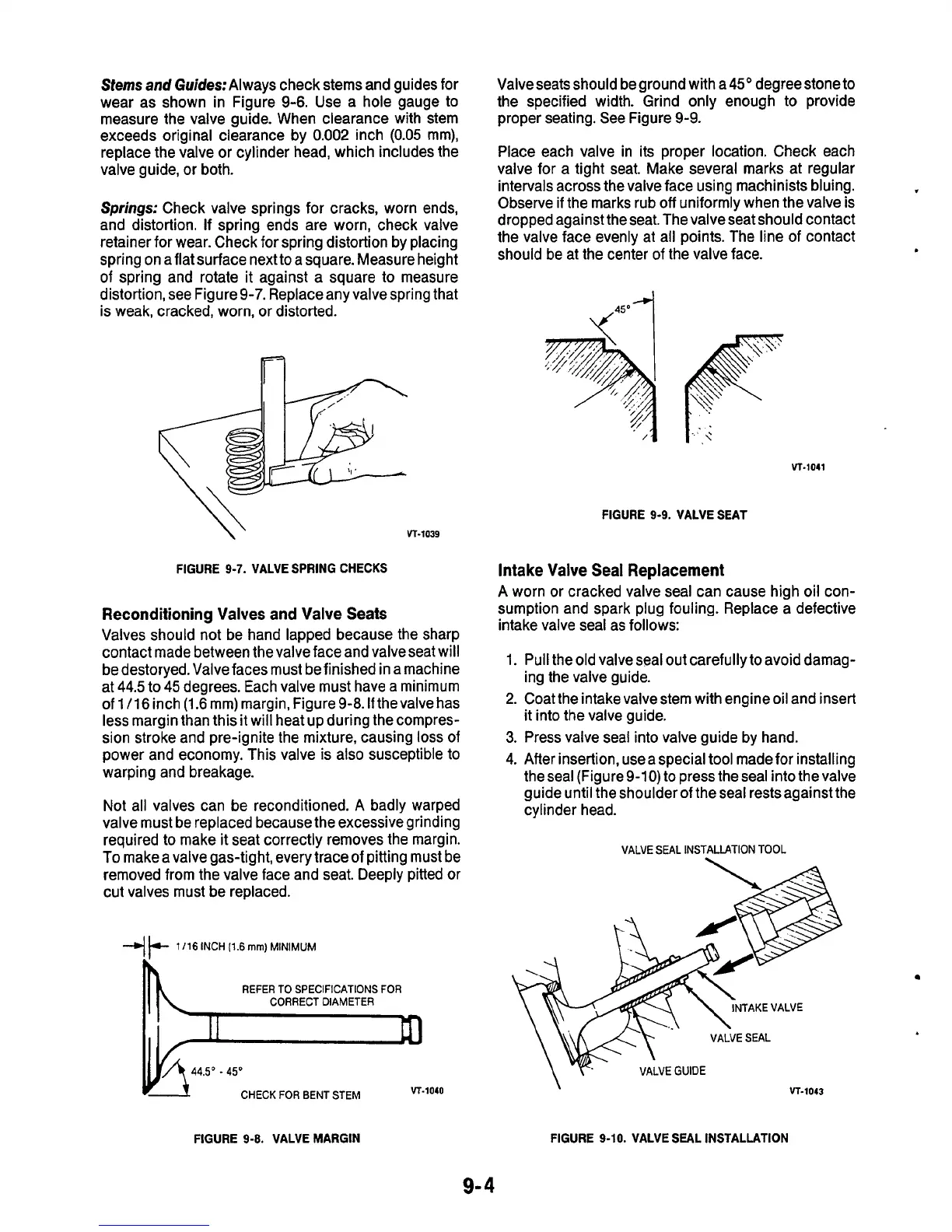

Valves should not be hand lapped because the sharp

contact made between thevalve face and valveseat will

be destoryed. Valve faces must be finished in a machine

at

44.5

to

45

degrees. Each valve must have a minimum

of 1/16inch

(1.6mm)margin,Figure9-8.Ifthevalvehas

less margin than this

it

will heat up during the compres-

sion stroke and pre-ignite the mixture, causing

loss

of

power and economy. This valve

is

also susceptible to

warping and breakage.

Not

all valves can be reconditioned.

A

badly warped

valve must be replaced because the excessive grinding

required to make

it

seat correctly removes the margin.

To

make a valve gas-tight, every trace of pitting must be

removed from the valve face and seat. Deeply pitted

or

cut valves must be replaced.

6

INCH

(1.6

rnm)

MINIMUM

REFER TO SPECIFICATIONS FOR

CORRECT DIAMETER

II

44.50

-

450

vT.1040

CHECK

FOR

BENT STEM

Valve seats should be ground with a

45'

degree stone to

the specified width. Grind only enough to provide

proper seating. See Figure

9-9.

Place each valve in its proper location. Check each

valve for a tight seat. Make several marks at regular

intervals across the valve face using machinists bluing.

Observe if the marks rub

off

uniformly when the valve is

dropped against the seat. The valve seat should contact

the valve face evenly at all points. The line of contact

should be at the center of the valve face.

VI-1041

FIGURE

9-9.

VALVE SEAT

Intake Valve Seal Replacement

A

worn or cracked valve seal can cause high oil con-

sumption and spark plug fouling. Replace a defective

intake valve seal as follows:

1.

Pull the old valve seal out carefully to avoid damag-

2.

Coat the intake valve stem with engine oil and insert

3.

Press valve seal into valve guide by hand.

4.

After insertion, usea special tool made for installing

the seal (Figure

9-1

0)

to press the seal into the valve

guide until the shoulder of the seal restsagainst the

cylinder head.

ing the valve guide.

it

into the valve guide.

VALVE

SEAL

INSTALLATION TOOL

\

VALVE SEAL

e'lL"E-GulDE

VT-1043

\

FIGURE

9-8.

VALVE MARGIN

FIGURE

9-10.

VALVE SEAL INSTALLATION

9-

4

Loading...

Loading...