OPERATING

LEVER

I

PUMP TAPP

CAM GEAR

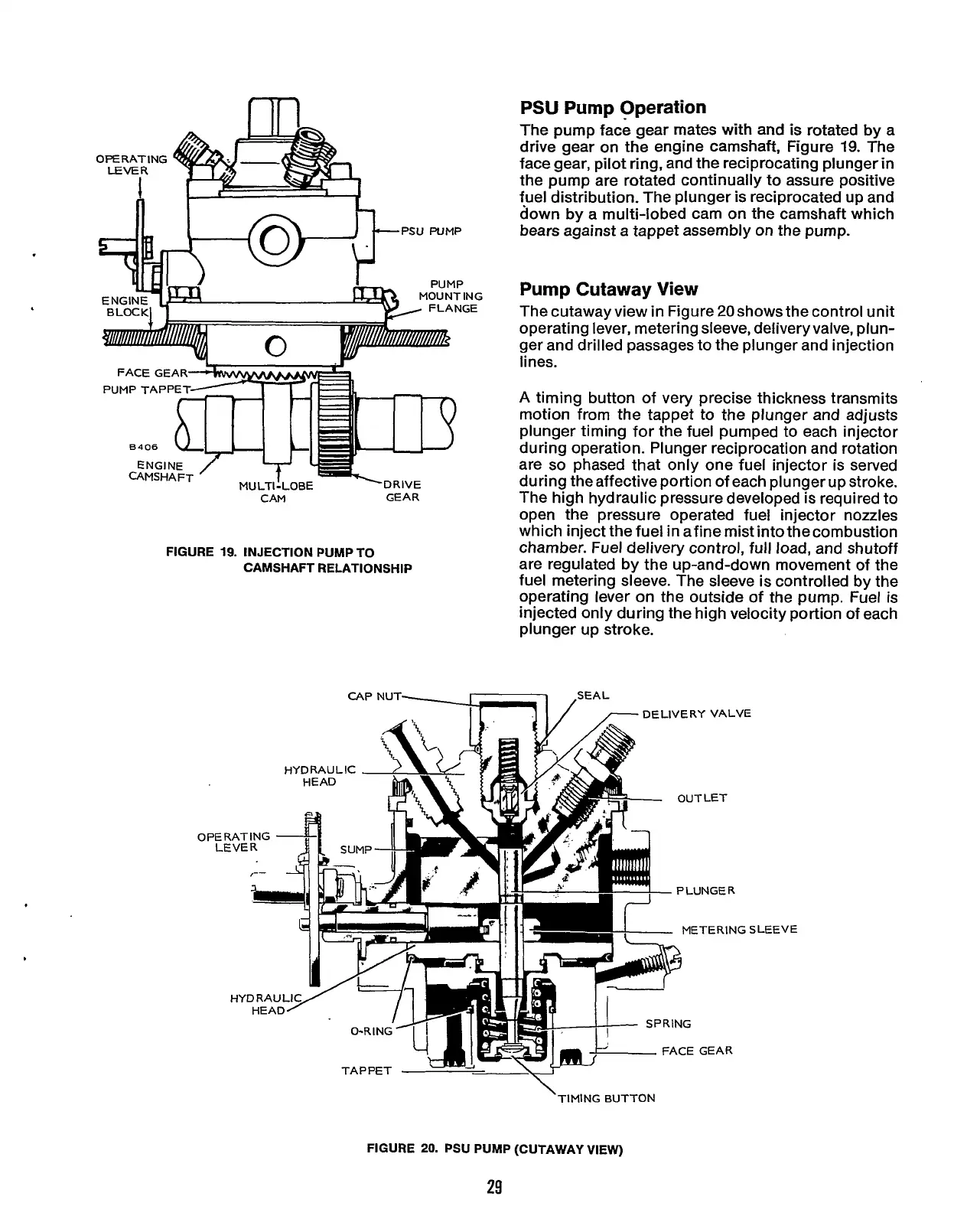

FIGURE

19.

INJECTION PUMP TO

CAMSHAFT RELATIONSHIP

0

PE

L

PSU

Pump Operation

The pump face gear mates with and is rotated by a

drive gear on the engine camshaft, Figure

19.

The

face gear, pilot ring, and the reciprocating plunger in

the pump are rotated continually to assure positive

fuel distribution. The plunger is reciprocated up and

down by a multi-lobed cam on the camshaft which

bears against a tappet assembly on the pump.

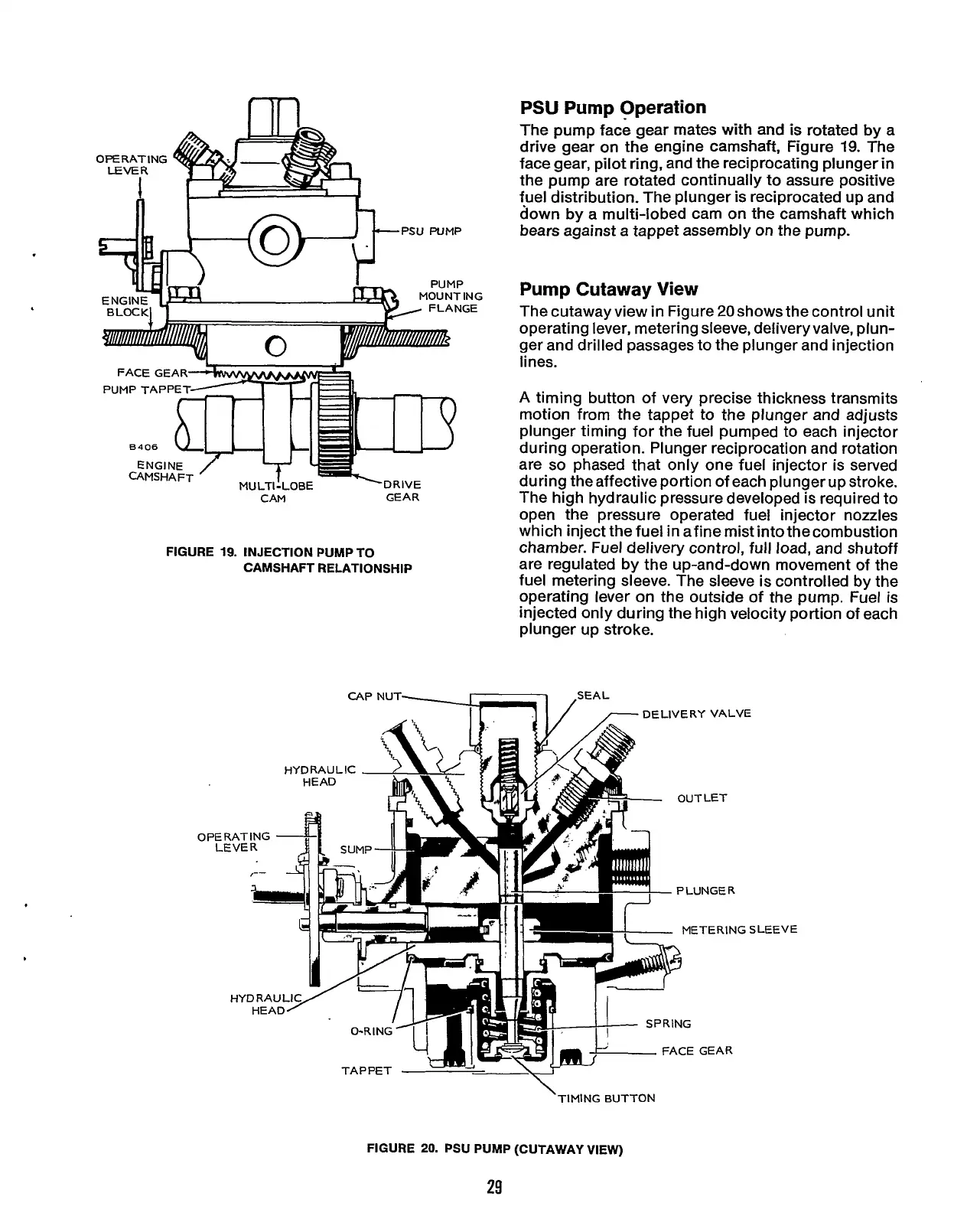

Pump Cutaway View

The cutawayview in Figure 20shows the control unit

operating lever, metering sleeve, delivery valve, plun-

ger and drilled passages to the plunger and injection

lines.

A

timing button of very precise thickness transmits

motion from the tappet to the plunger and adjusts

plunger timing for the fuel pumped to each injector

during operation. Plunger reciprocation and rotation

are

so

phased that only one fuel injector is served

during theaffective portion of each plunger up stroke.

The high hydraulic pressure developed is required to

open the pressure operated fuel injector nozzles

which inject the fuel in afine mist into the combustion

chamber. Fuel delivery control, full load, and shutoff

are regulated by

the

up-and-down movement of the

fuel metering sleeve. The sleeve is controlled by the

operating lever on the outside

of

the pump. Fuel is

injected only during the high velocity portion of each

plunger up stroke.

HYD RAULlC

OUTLET

1

PLUNGER

i

METERING

SI

\

HY

-EEVE

TIMING BUTTON

FIGURE

20.

PSU PUMP (CUTAWAY

VIEW)

29

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...