Fuel

System

DIESEL FUEL

Diesel fuel, like gasoline and most gaseous fuels, is a

product of crude oil refining. Its heat content is

somewhat higher than that of gasoline.

In a diesel engine, fuel is sprayed into the combustion

chamber as the piston approaches the top of its com-

pression stroke. The fuel is ignited by the intense heat

that develops as the air within the engine cylinder is

compressed.

No

electrical ignition system is

necessary.

Diesel fuel requirements vary with engine size, speed

and load, and with ambient temperature. Factors

which must be considered include the fuel's cetane

number, pour point, viscosity, volatility, and the

amount of sediment, residues, and sulfur in the fuel.

The American Society for Testing Materials (ASTM)

has used these and other characteristics to define

three basic diesel fuel grades. Refer to the Service

and Maintenance section for the recommended grade

of fuel to use in the engine.

Cetane Rating

Cetane number is a measure of how quickly diesel

fuel will ignite under heat and pressure. For proper

engine operation, diesel fuel should ignite almost

immediately after entering the engine combustion

chamber. If ignition is delayed, too much fuel will

ignite at once, causing sudden explosions. These

explosions produce the familiar cackle heard when a

diesel engine is'cold or at idle. If the cackle does not

disappear as the engine is warmed or placed under

load,

it

is a sign that the cetane rating of the fuel may

be too low, which could cause serious engine

damage.

KEEP

FUEL

CLEAN!

0

DIRTY FUEL

IS

ONE OF THE MAJOR CAUSES OF

ENGINE FAILURE

0

REMEMBER- EVEN A TINY PARTICAL

OF

DIRT

IN

THE INJECTION SYSTEM MAY STOP YOUR ENGINE!

0

Pour

Poi

n

t

The temperature at which a diesel fuel will cease to

flow is known as its pour point. As diesel fuels

approach their pour point, waxes form and plug fuel

filters causing fuel starvation. For this reason, if low

ambient temperatures are possible, diesel fuel with a

pour point at least

10

degrees

F

(6°C) below the

lowest expected temperature should be specified.

Keeping Diesel Fuel Clean

and

Free From Water

It is essential that diesel fuel be kept clean and free

from water. Diesel injection pumps and nozzles are

precision-made units requiring extremely close tol-

erances. They are very sensitive to any abrasive

materials and are easily damaged by corrosion result-

ing from the introduction of water into the system.

To keep fuel contamination

to

a minimum, the fuel

storage and system maintenance procedures out-

lined below must be followed.

1.

Do not use zinc or galvanized storage tanks as

harmful compounds may form as a result of reac-

tions with diesel fuel impurities.

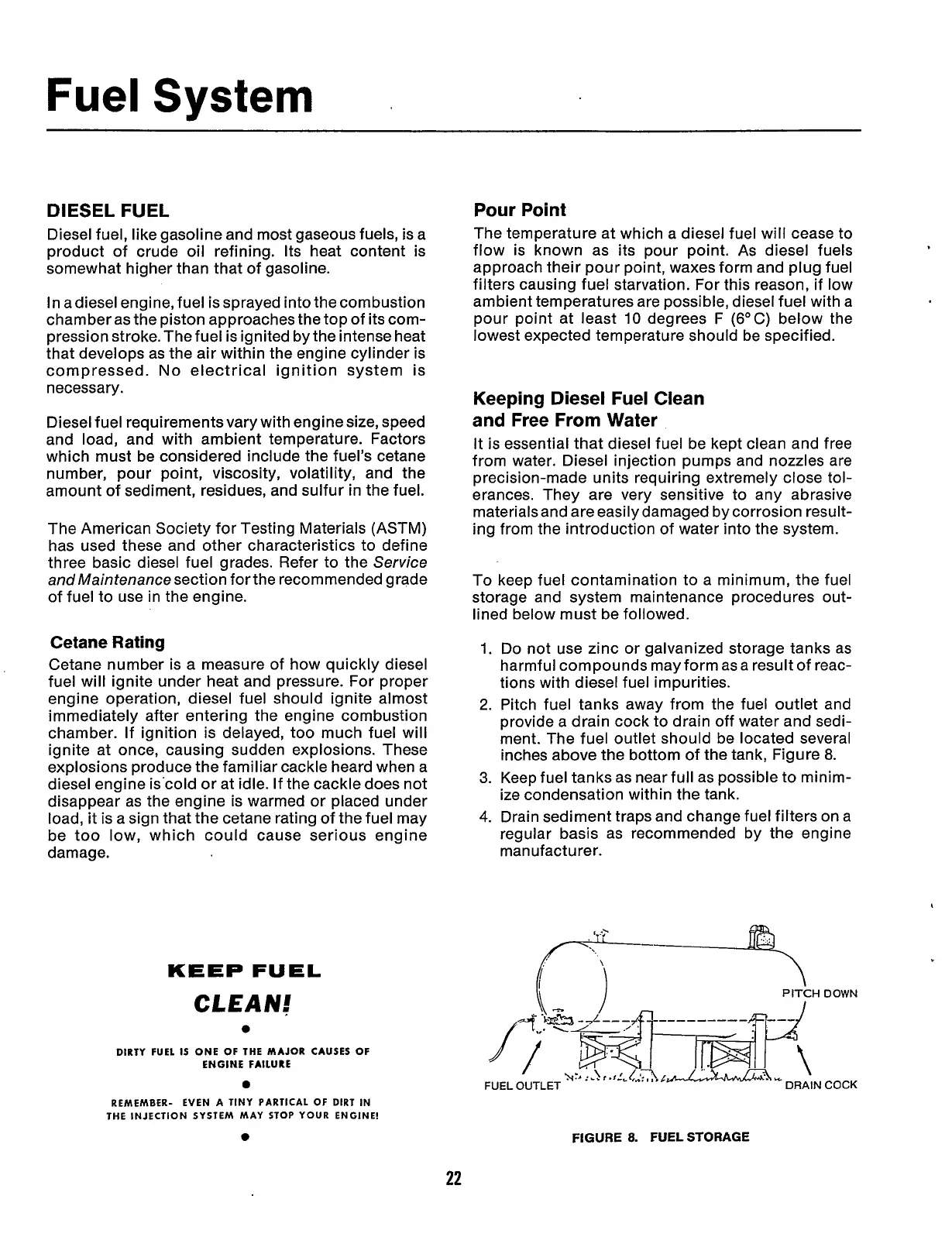

2.

Pitch fuel tanks away from the fuel outlet and

provide a drain cock to drain off water and sedi-

ment. The fuel outlet should be located several

inches above the bottom of the tank, Figure

8.

3.

Keep fuel tanks as near full as possible to minim-

ize condensation within the tank.

4.

Drain sediment traps and change fuel filters on a

regular basis as recommended by the engine

manufacturer.

FIGURE

8.

FUEL

STORAGE

22

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...