When the tappet slips off each lobe of the camshaft,

the spring loaded plunger is forced down opening the

fuel supply port to the fuel sump. This allows fuel

under low pressure from the transfer pump and fuel

sump to fill the cavity between the top end of the

plunger and the delivery valve. The plunger is then

ready for the up stroke.

-

.lo1

.098

.095

,092

-089

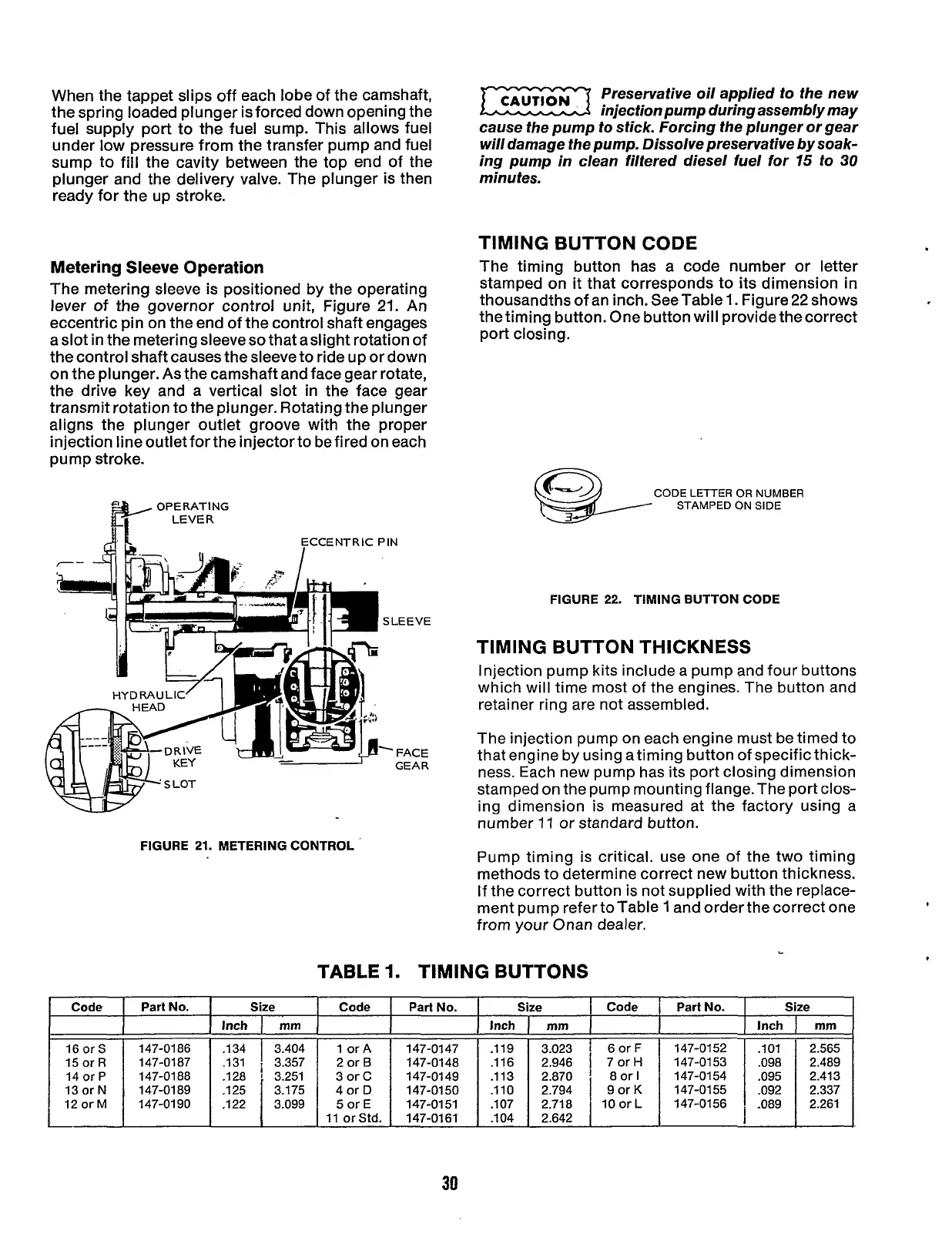

Metering Sleeve Operation

The metering sleeve is positioned by the operating

lever

of

the governor control

unit,

Figure

21.

An

eccentric pin on the end of the control shaft engages

a slot in the metering sleeveso that aslight rotation of

the control shaft causes the sleeve to ride up or down

on the plunger. As the camshaft and face gear rotate,

the drive key and a vertical slot in the face gear

transmit rotation to the plunger. Rotating the plunger

aligns the plunger outlet groove with the proper

injection line outlet for the injector to be fired on each

pump stroke.

2.565

2.489

2.413

2.337

2.261

ECCENTRIC PIN

F

SLEEVE

-

FACE

GEAR

Code

16

or

S

15

or

R

14

or

P

13

or

N

12

or

M

FIGURE

21.

METERING CONTROL

Part

NO.

I

C

I

Inch

147-01

88

147-01 89 .125

147-01 90

Preservative oil applied to the new

injection pump during assembly may

cause the pump to stick. Forcing the plunger or gear

will damage the pump. Dissolve preservative by soak-

ing pump in clean filtered diesel fuel for

75

to

30

minutes.

TIMING BUTTON CODE

The timing button has a code number or letter

stamped on

it

that corresponds to its dimension

in

thousandths of an inch. See Table

I.

Figure

22

shows

the timing button. One button will provide the correct

port closing.

CODE LETTER

OR

NUMBER

STAMPED ON SIDE

FIGURE

22.

TIMING BUTTON CODE

TIMING BUTTON THICKNESS

Injection pump kits include a pump and four buttons

which will time most of the engines. The button and

retainer ring are not assembled.

The injection pump on each engine must be timed to

that engine by using a timing button of specific thick-

ness. Each new pump has its port closing dimension

stamped on the pump mounting flange. The port clos-

ing dimension is measured at the factory using a

number

17

or standard button.

Pump timing is critical. use one of the two timing

methods to determine correct new button thickness.

If the correct button

is

not supplied with the replace-

ment pump refer to Table

1

and order the correct one

from your Onan dealer.

I

L

TABLE

1.

TIMING

BUTTONS

e

I

Code

I

Part No.

rnrn

I

147-01 51

Size

Inch

I

rnm

2.794

2.71

8

2.642

Code

~

6orF

7

or

H

8

or

I

9orK

10

or

L

Part

No.

147-01 52

147-01 53

147-01 54

147-01

55

147-01 56

I

30

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...