16

Customer Helpline

0844 801 3652

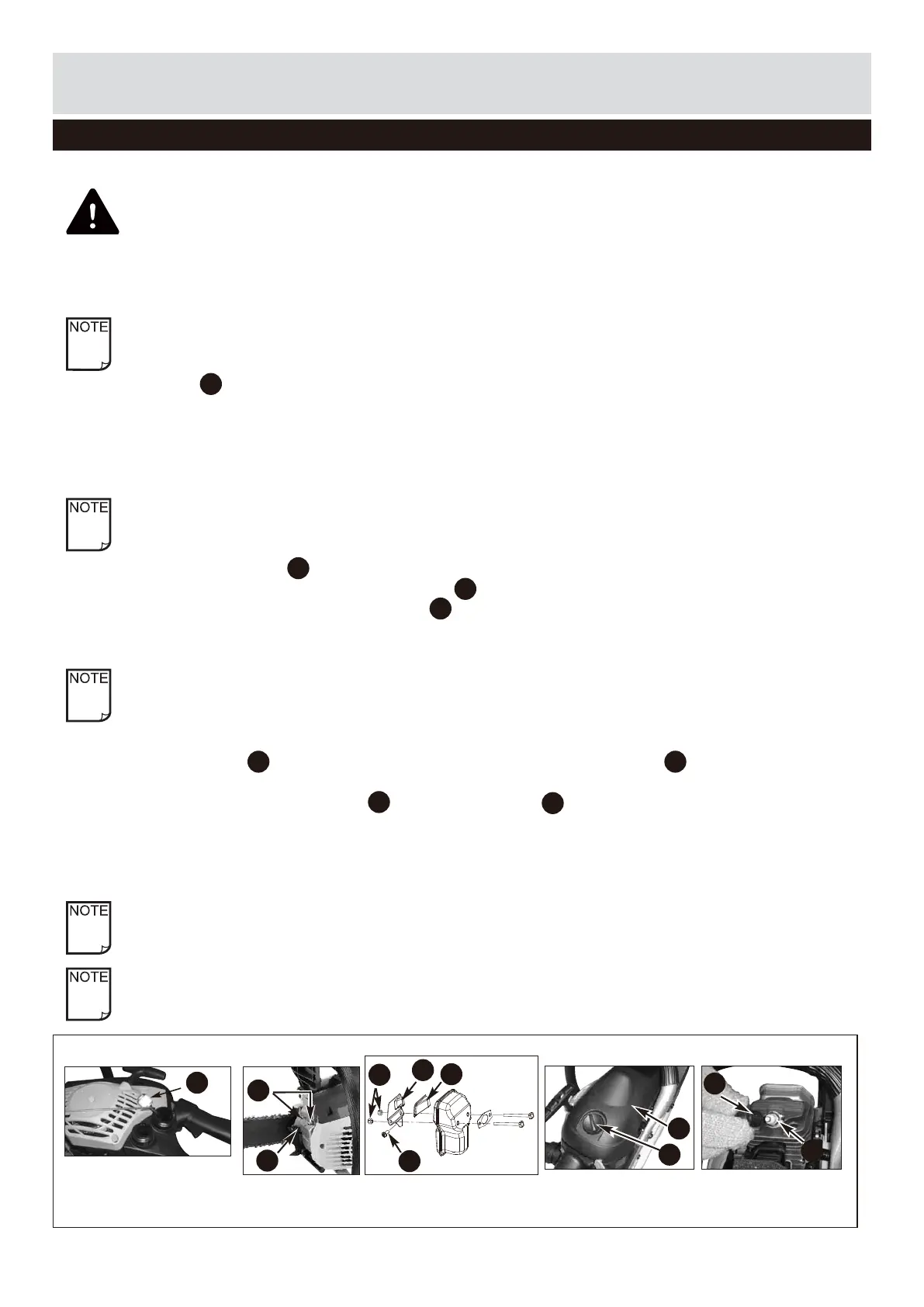

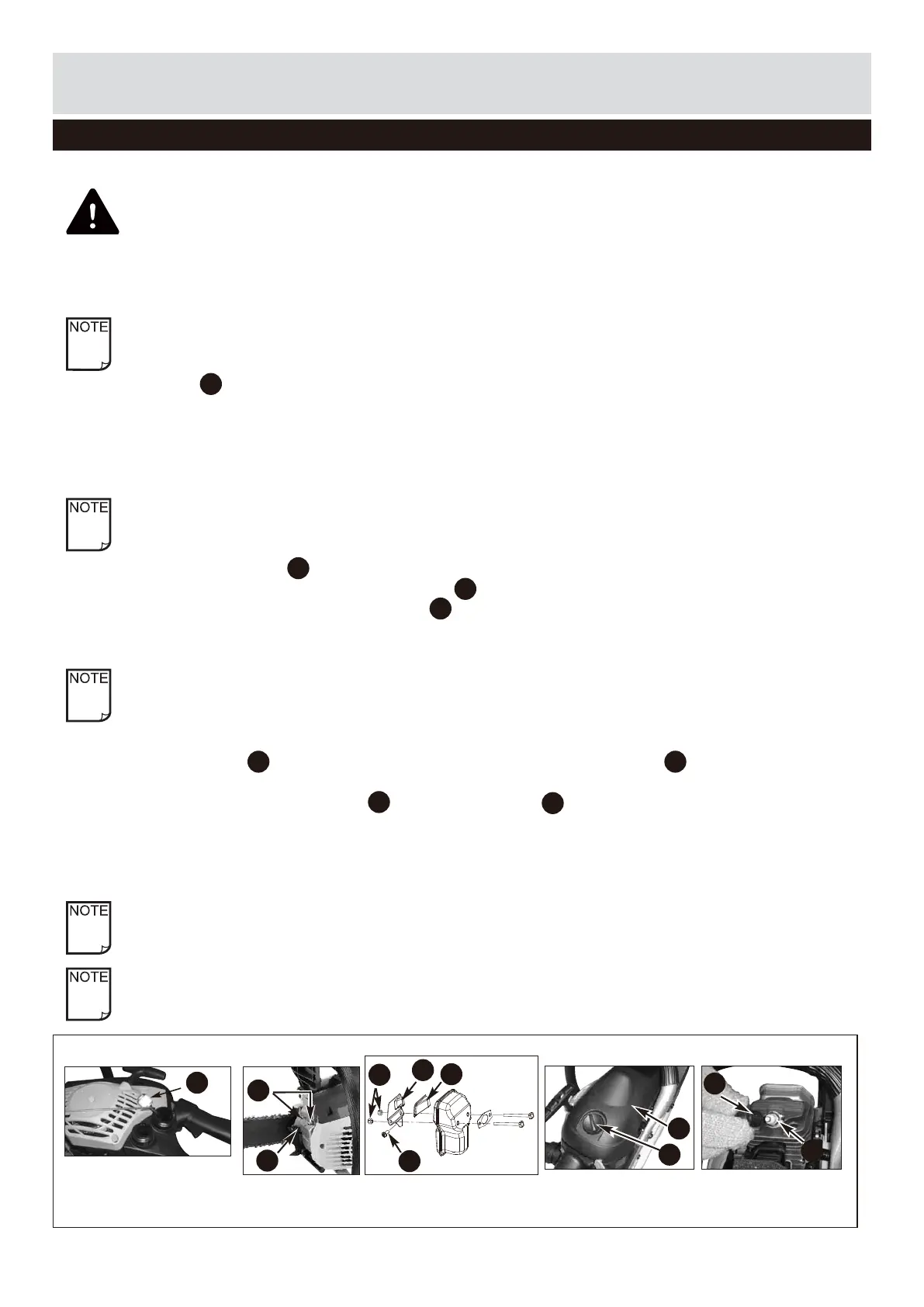

Fig. 17A

A

Fig. 17B

B

C

B

B

D

Fig. 18A

A

Fig. 18B

C

D

B

Fig. 16

A

SPARK PLUG

Maintenance

Maintenance instructions

FUEL FILTER

SPARK ARRESTER SCREEN

1. Remove the fuel tank cap.

2. Bend a piece of soft wire to from a hook at the end.

3. Reach into fuel tank opening and hook fuel line. Carefully pull the fuel line toward the opening until

you can reach it with your ngers.

1. Remove the 2 bolts (A) and pull mufer out. (Fig. 17A).

2. Remove the 2 screws that holds the cover (C). (Fig.17B)

3. Discard the used spark arrester screen (D) and replace it with a new one.

4. Reasemble the mufer components and install the mufer to the cylinder. Tighten securely.

4. Lift lter (A) out of tank (Fig.16).

5. Pull lter off with a twisting motion. Discard lter.

6. Install new lter. Insert end of lter into tank opening. Make sure lter sits in bottom corner of tank.

Use a long screwdriver to aid in lter placement if necessary.

7. Fill tank with fresh fuel / oil mixture. See Section FUEL AND LUBRICATION. Install fuel cap.

WARNING: Never operate your saw without a fuel lter. The fuel lter should be replaced after each

20 hours of use. Drain fuel tank completely before changing lter.

NOTE: Do not pull hose completely out of tank.

NOTE: A clogged spark arrester screen will dramatically reduce engine performance.

1. Push STOP switch down.

2. Remove knob (A) holding air lter cover in place, remove the top cover (B) by loosening the cover

retaining screws. Cover will lift off. (Fig.18A)

3. Disconnect the wire connector (C) from the spark plug (D) by pulling and twisting at the same time

(Fig. 18B).

4. Remove spark plug with spark plug socket wrench. DO NOT USE ANY OTHER TOOL.

5. Check electrode gaps with wire feeler gauge and set gaps to .025” (.635mm) if necessary.

6. Reinstall a new spark plug.

NOTE: For efcient operation of saw engine, spark plug must be kept clean and properly gapped.

NOTE: A resistor spark plug must be used for replacement.

NOTE: This spark ignition system meets all requirements of the Interference-Causing Equipment

Regulations.

A

17

A

A

17

16

B

B

B

16

D

D

D

D

C

C

C

C

A

Loading...

Loading...