19

Troubleshooting

9 Troubleshooting

The motor or driver may not operate properly if the rotation speed is wrongly set or the connection is wrong.

If the motor cannot operate properly, refer to the contents provided in this chapter and take appropriate action.

If the problem persists, contact your nearest Oriental Motor sales oce.

Note

Check the alarm contents when an alarm is generated.

The motor does not rotate.

●

The power supply is not connected correctly or it is improper connection.

▷

Check the connection of the power supply.

●

The operation input signal is not turned ON.

▷

Check if both the START/STOP input and the RUN/BRAKE input are turned ON.

●

The M0 input is selected wrongly. Or the motor connector is not connected

properly.

▷

Check the M0 input.

ON: VR1 OFF: External analog setting device

●

An alarm is present.

▷

Check if an alarm is generated.

The PWR/ALM LED blinks in red while an alarm is present.

For alarm contents, check the number of times the LED blinks.

Refer to p.21, and reset the alarm after removing the cause of the alarm.

・

A time for stopping is long.

・

The stopping method is

wrong.

●

The stopping method is wrongly selected.

▷

Check the stopping method. The stop movement when turning the RUN/BRAKE input

OFF is dierent from that when turning the START/STOP input OFF. Refer to p.15 for details.

●

The deceleration time is too long.

▷

Check the setting of the acceleration time and deceleration time.

●

Load inertia is too large.

▷

Check by increasing the frictional load or reducing the load inertia.

The motor rotates in the

opposite direction to the

specied one.

●

The ON-OFF operation of the FWD/REV input is used wrongly or the FWD/REV

input is not connected correctly.

▷

Check the connection and the ON-OFF status of signal.

●

The gearhead with a reduction ratio which rotation direction is opposite to the

motor output shaft is used. (Refer to p.16 for the rotation direction of the gearhead

output shaft)

▷

Reverse the ON-OFF operation of the FWD/REV input.

●

A hollow shaft at gearhead is used.

▷

The hollow shaft at gearhead rotates in the opposite direction to the motor when

viewed from the front side of the gearhead, and rotates in the same direction to the

motor when viewed from the rear side (motor mounting side).

・

The motor movement is

not stable.

・

Motor vibration is too

large.

●

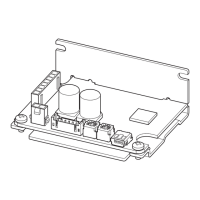

The motor and gearhead output shaft and a load shaft are out of alignment.

▷

Check the coupling condition of the motor and gearhead output shaft and the load

shaft.

●

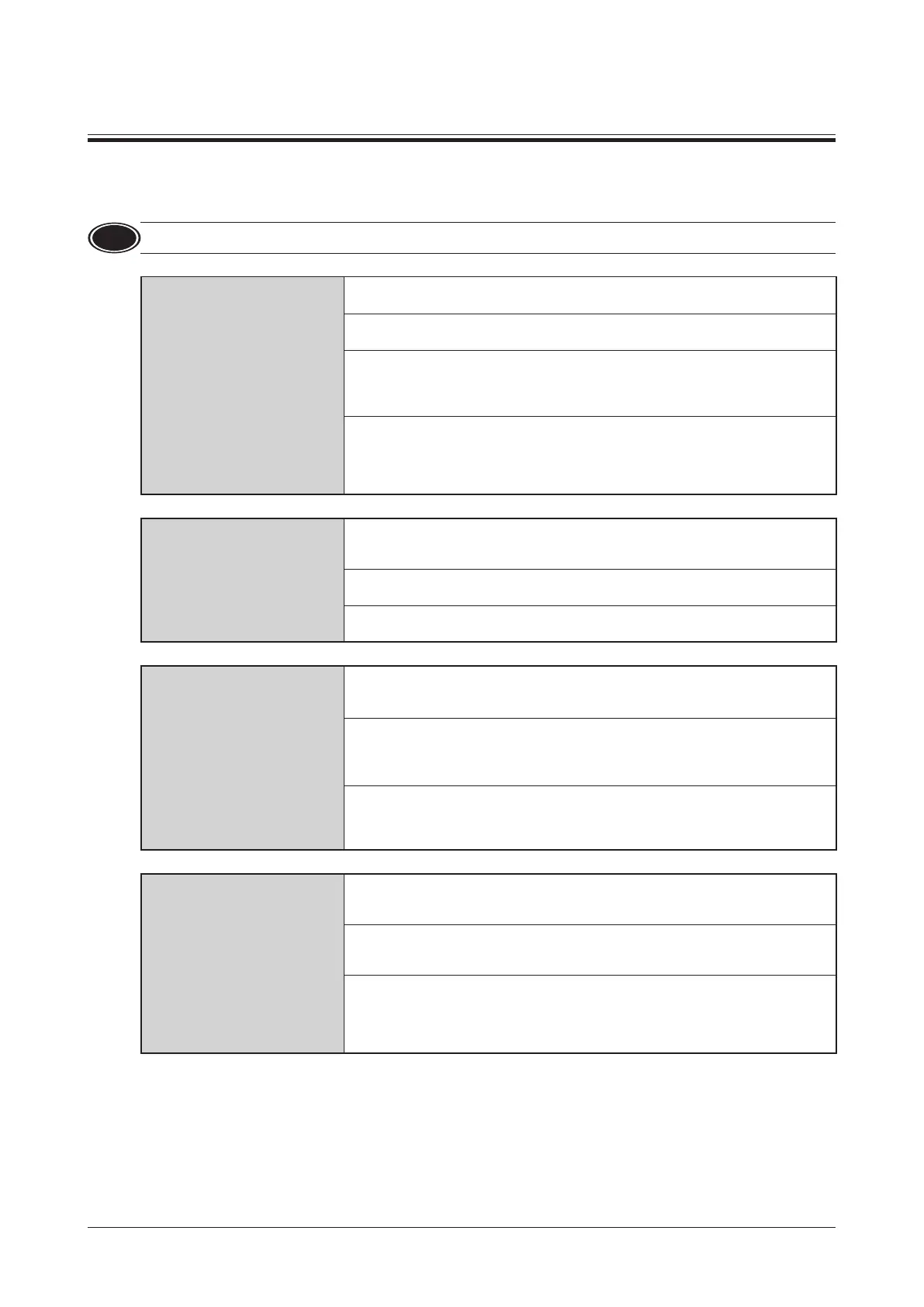

The motor output power and the driver output power are not matched.

▷

Check if the motor output power and the driver output power are the same.

For the output power, check the nameplates of the motor and driver.

●

The product is aected by electrical noise.

▷

Check the operation using the motor, driver and a minimum of external equipment

required for operation. If an eect of noise has been conrmed, implement the following

countermeasures:

[Keep away from the noise sources.] [Reconsider the wiring.]

Loading...

Loading...