1

Introduction

Before using the product

Only qualied personnel of electrical and mechanical engineering should work

with the product.

Use the product correctly after thoroughly reading the section "Safety

precautions."

In addition, be sure to observe the contents described in warning, caution, and

note in this manual. The product described in this document has been designed

and manufactured to be incorporated in general industrial equipment. Do not

use for any other purpose. For the power supply, use a DC power supply with

reinforced insulation on its primary and secondary sides. Oriental Motor Co.,

Ltd. is not responsible for any damage caused through failure to observe this

warning.

Operating manuals for the product

Operating manuals for this product are listed below.

For details about connections and operations, refer to the operating manual

included with the driver or the brushless motor and driver package.

BLHM

Motor OPERATING MANUAL (this document)

This manual explains the functions as well as the installation method and others

for the motor.

BLH

Series OPERATING MANUAL (included with the driver)

This manual explains the functions as well as the installation/connection

methods and others for the driver.

BLH

Series Digital setting type USER MANUAL

This manual does not come with the product. For details, contact your nearest

Oriental Motor sales oce or download from Oriental Motor Website Download

Page.

Safety precautions

The precautions described below are intended to ensure the safe and correct

use of the product, and to prevent the customer and others from exposure to

the risk of injury.

Use the product only after carefully reading and fully understanding these

instructions.

Handling the product without observing the

instructions that accompany a "WARNING" symbol

may result in serious injury or death.

Handling the product without observing the

instructions that accompany a “CAUTION” symbol

may result in injury or property damage.

Note

The items under this heading contain important

handling instructions that the user should observe

to ensure safe use of the product.

[Description of graphic symbols]

:

Indicates "prohibited" actions that must not be performed.

: Indicates "compulsory" actions that must be performed.

Do not use the product in explosive or corrosive environments, in the

presence of ammable gases, locations subjected to splashing water,

or near combustibles. Doing so may result in re or injury.

Do not move, install, connect or inspect the product while the power

is supplied. Always turn o the power before carrying out these

operations. Damage to equipment may result.

HM-5238

OPERATING MANUAL

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety

precautions.

Please read it thoroughly to ensure safe operation.

Always keep the manual where it is readily available.

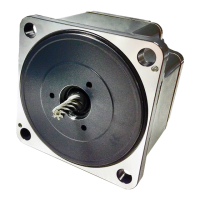

Brushless Motor

BLHM

Motor

Do not use a motor in a vertical application. If the driver protective

function is activated, the motor will stop and the moving part may

drop, thereby causing injury or damage to equipment.

Do not machine or modify the motor cable or connection cable. Doing

so may result in re or damage to equipment.

Do not forcibly bend, pull or pinch the cable. Doing so may result in

re or damage to equipment.

Do not touch the motor and driver when conducting the insulation

resistance measurement or dielectric strength test. Accidental contact

may result in electric shock.

Do not disassemble or modify the motor and gearhead. Doing so

may result in injury or damage to equipment. Refer all such internal

inspections and repairs to the branch or sales oce from which you

purchased the product.

Only qualied and educated personnel should be allowed to perform

installation, connection, operation and inspection/troubleshooting of

the product. Handling by unqualied and uneducated personnel may

result in re, injury or damage to equipment.

Use a motor, gearhead, and driver only in the specied combination.

An incorrect combination may cause re or damage to equipment.

Install the motor, gearhead and driver in an enclosure. Failure to do so

may result in injury.

Do not use the motor and gearhead beyond the specications. Doing

so may result in re, injury or damage to equipment.

Do not touch the motor and gearhead while operating or immediately

after stopping. The surfaces of the motor and gearhead are hot, and it

may cause a skin burn(s).

Do not leave anything around the motor that would obstruct

ventilation. Doing so may result in damage to equipment.

Do not move the product by holding the output shaft of the motor or

the gearhead, or the motor cable. Doing so may result in injury.

Do not touch the motor output shaft (end or pinion) with bare hands.

Doing so may cause injury.

When assembling the motor (pinion shaft) with the gearhead, exercise

caution not to pinch your ngers or other parts of your body between

the motor and gearhead. Injury may result.

When installing the motor or gearhead in the equipment, exercise

caution not to pinch your ngers or other parts of your body between

the equipment and motor or gearhead. Injury may result.

Do not touch the rotating part (output shaft) while operating the

motor. Doing so may cause injury.

Securely install the motor and gearhead to the mounting plate.

Inappropriate installation may cause the motor and gearhead to

detach and fall, resulting in injury or damage to equipment.

Provide a cover over the rotating part (output shaft) of the motor or

gearhead. Failure to do so may result in injury.

Securely install a load on the output shaft of the motor or gearhead.

Inappropriate installation may result in injury.

Be sure to ground the motor and driver to prevent them from being

damaged by static electricity. Failure to do so may result in re or

damage to equipment.

The motor surface temperature may exceed 70°C (158°F)

even under normal operating conditions. If the operator

is allowed to approach the motor in operation, attach a

warning label in a conspicuous position as shown in the

gure. Failure to do so may result in a skin burn(s).

Warning label