2

Checking the product

This section explains the items you should check, as well as the name and

function of each part.

Package contents

Verify that the items listed below are included.

Report any missing or damaged items to the branch or sales oce from which

you purchased the product.

z

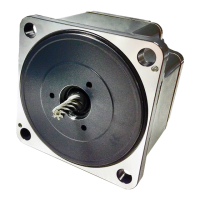

Geared type, round shaft type

□

Motor ...............................................................1 pc

(the geared type is a motor with a gearhead)

□

Operating Manual (this document) ......1 pc

z

Combination type-parallel shaft gearhead

□

Motor ...............................................................1 pc

(a gearhead is pre-assembled)

□

Mounting screw set ....................................1 set

(hexagonal socket head screw, plain washer, spring washer, nut each 4 pcs, parallel key 1pc)

□

Operating Manual (this document) ......1 pc

z

Combination type-hollow shaft at gearhead

□

Motor ...............................................................1 pc

(a gearhead is pre-assembled)

□

Mounting screw set ....................................1 set

(hexagonal socket head screw, plain washer, spring washer, nut each 4 pcs, parallel key 1pc)

□

Safety cover set ............................................1 set

(safety cover 1 pc, mounting screw for safety cover 2 pcs)

□

Operating Manual (this document) ......1 pc

Model

Verify the model name of the purchased product against the model shown on

the package label.

Check the motor model and the gearhead model against the model name

shown on their nameplates, respectively.

Tell us the model name, product serial number, and manufacturing date when

you contact us.

The box (

o

) in the model name indicates a number representing the gear

ratio.

z

Geared type

Output power Model

15 W

BLHM015K-

o

z

Combination type-parallel shaft gearhead

Output power Model

Motor model

Gearhead

model

30 W

BLHM230KC-

o

BLHM230KC-GFS GFS2G

o

50 W

BLHM450KC-

o

BLHM450KC-GFS GFS4G

o

100 W

BLHM5100KC-

o

BLHM5100KC-GFS GFS5G

o

For the lead wire type, "

KC

" of the model and motor model are replaced by "

K

".

z

Combination type-hollow shaft at gearhead

Output power Model

Motor model

Gearhead

model

30 W

BLHM230KC-

o

FR BLHM230KC-GFS GFS2G

o

FR

50 W

BLHM450KC-

o

FR BLHM450KC-GFS GFS4G

o

FR

100 W

BLHM5100KC-

o

FR BLHM5100KC-GFS GFS5G

o

FR

For the lead wire type, "

KC

" of the model and motor model are replaced by "

K

".

z

Round shaft type

Output power Model

15 W

BLHM015K-A

30 W

BLHM230KC-A

50 W

BLHM450KC-A

100 W

BLHM5100KC-A

For the lead wire type, "

KC

" of the model is replaced by "

K

" (except for

BLHM015

type).

Precautions for use

This section explains limitations and requirements the user should consider

when using the product.

z

Be sure to match the motor output power with the driver output

power.

z

Connecting the motor and driver

Use a connection cable (sold separately) when extending the wiring distance

between the motor and the driver. The maximum extension distance including

the length of the motor cable should be 2 m (6.6 ft.).

z

Do not perform gravitational operation (vertical drive)

If this product is performed operation (i.e. gravitational operation) in which the

motor output shaft is turned from the load side, the motor speed cannot be

controlled. In addition, gravitational operation will cause the primary inverter

voltage of the driver to exceed the permissible value, thereby triggering the

protective function and causing the motor to coast to a stop. If this happens,

there is a possibility that the load will drop.

z

Grease measures

On rare occasions, grease may ooze out from the gearhead. If there is concern

over possible environmental contamination resulting from the leakage of

grease, check for grease stains during regular inspections. Alternatively, install

an oil pan or other device to prevent damage resulting from contamination.

Grease leakage may lead to problems in the user’s equipment or products.

z

Apply grease to the hollow output shaft of a hollow shaft at

gearhead

Apply grease (molybdenum disulde grease, etc.) on the surface of the load

shaft and inner walls of the hollow output shaft to prevent seizure.

z

Caution when using in low temperature environment

When an ambient temperature is low, since the load torque may increase by

the oil seal or viscosity increment of grease used in the gearhead, the output

torque may decrease or the overload alarm may generate. However, as time

passes, the oil seal or grease is warmed up, and the motor can be operated

without generating the overload alarm.

z

Rotation direction

For the rotation direction of the motor output shaft,

rotation in the clockwise direction when viewed from the

motor output shaft side represents "CW" and that in the

counterclockwise direction represents "CCW.”

W

Geared type, combination type-parallel shaft gearhead

The rotation direction of the gearhead output shaft may vary with that of the

motor output shaft depending on the gear ratio of the gearhead.

Geared type (15 W)

Gear ratio Rotation direction of the gearhead output shaft

5

,

10

,

15

,

50

,

100

Same direction as the motor

20

,

30

Opposite direction to the motor

Combination type-parallel shaft gearhead

Gear ratio Rotation direction of the gearhead output shaft

5

,

10

,

15

,

20

,

200

Same direction as the motor

30

,

50

,

100

Opposite direction to the motor

Combination type-hollow shaft at gearhead

At all gear ratios, the output shaft rotates in the opposite direction to the motor

as viewed from the gearhead front face.

With a combination type-hollow shaft at gearhead, the rotation direction

viewed from the gearhead front face is dierent from that viewed from the

gearhead rear face. Check with the gure below.

Viewed from Front Viewed from Rear

CW

CW

CCW

Loading...

Loading...