Orion Pulse Arc Welding Workbook

16

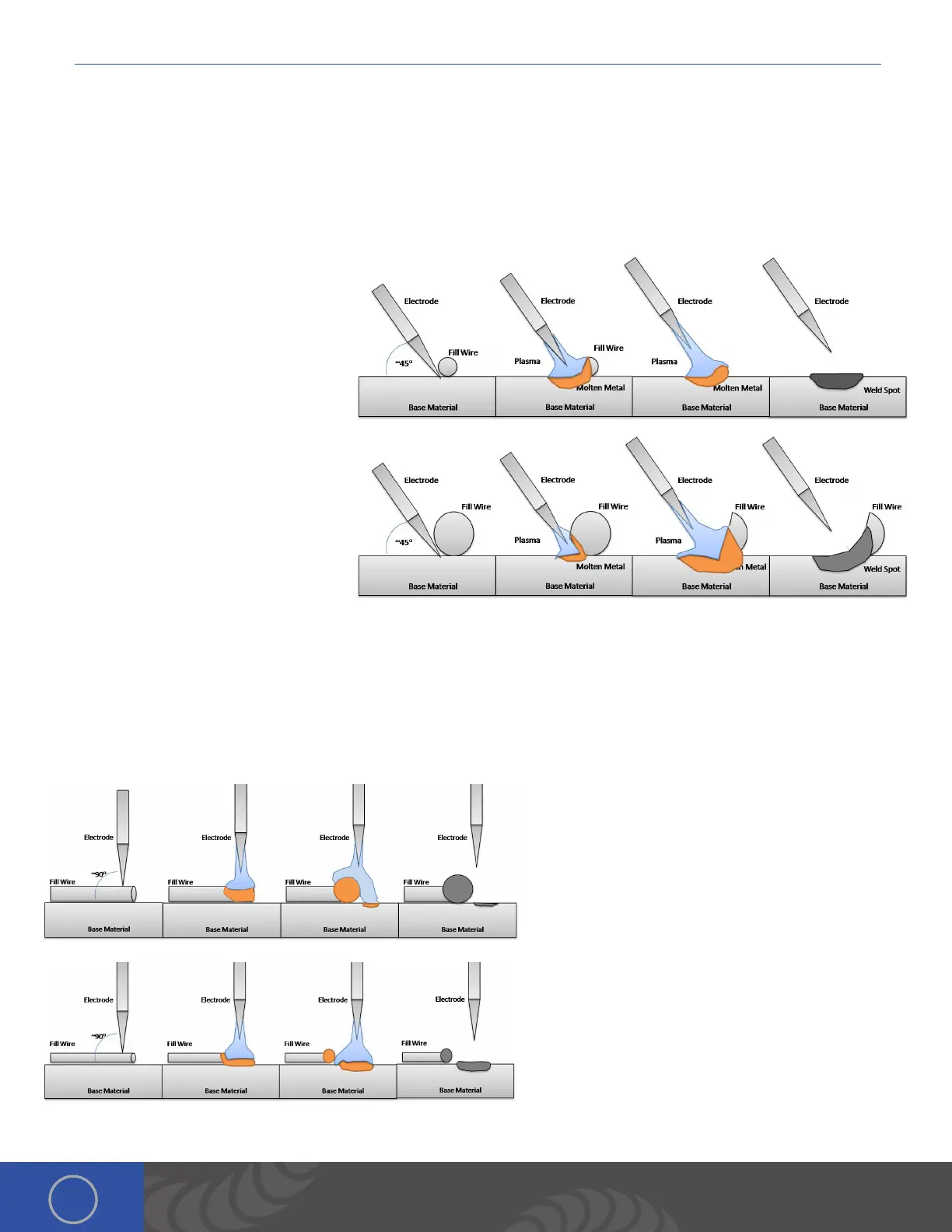

ere are several methods to aid in the addition of fill wire, which are mentioned below. e placement of the electrode

relative to the wire is very important and will influence how the material behaves during the addition process.

SIDE PLACEMENT: Placing the electrode on the side of the wire is generally the best method of adding fill wire. As shown

below, place the electrode at an approximate 45 degree angle between the wire and the base material. As the electrode

pulls away from the base material and the arc ignition happens, the base material will melt first and then the wire will be

melted and pushed or pulled (by surface tension) into the base material. is is an excellent method to produce a uniform

molten pool of metal and ensure the proper mixing of the base material and the fill wire. e electrode may also be placed

at a 45 degree angle in front of the wire.

However, less material will be added with

every weld, and a portion of the wire will

typically ball-up n the process.

Remember that for a larger fill wire the

energy must be increased to completely

melt the wire. If there is insufficient energy

there may only be partial melting of the

wire. However, in some situations this may

be advantageous.

HANDS ON: Try adding fill wire using the

side placement method. Build up a small

mound of material.

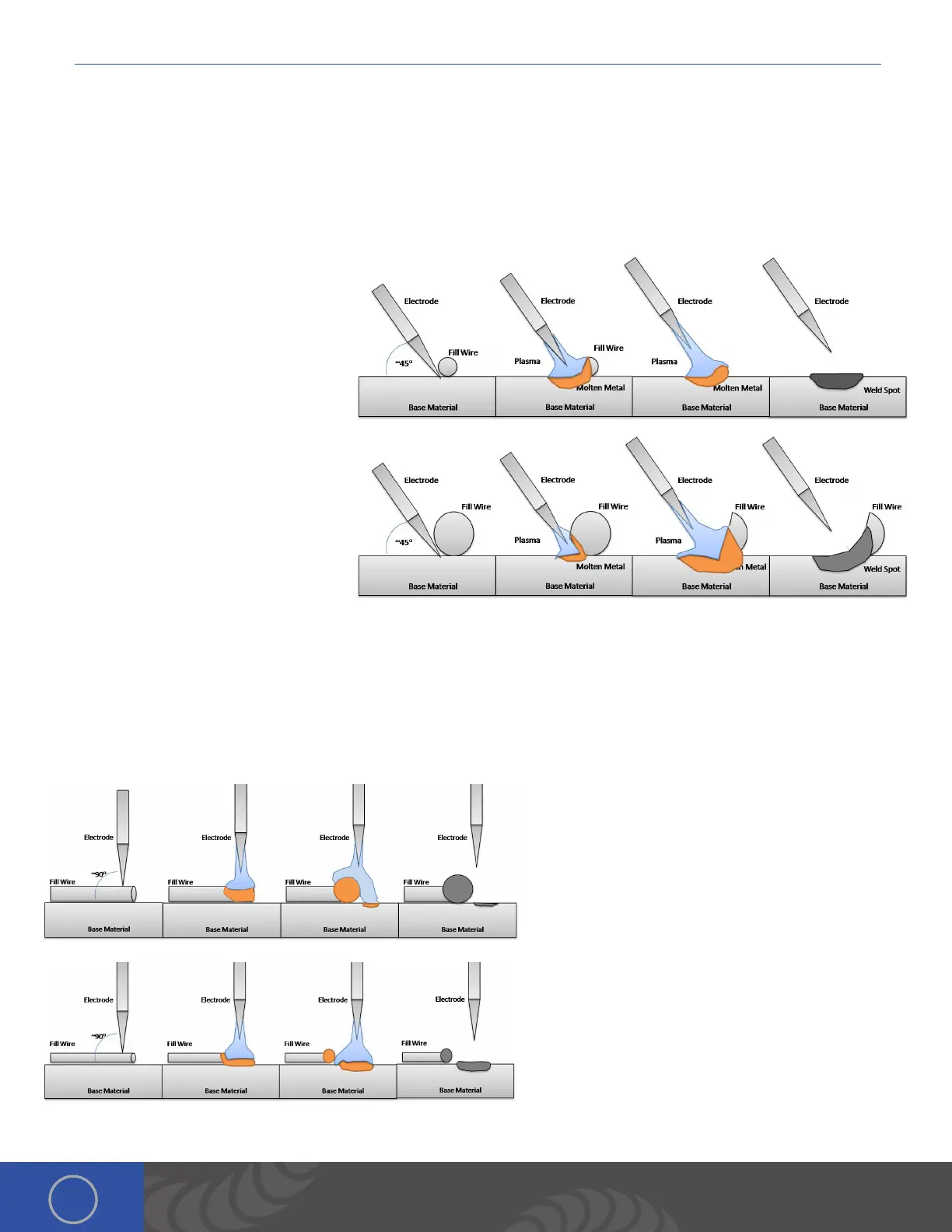

TOP PLACEMENT: With top placement the material addition process will depend a great deal on the wire size and the weld

energy. If the wire is very small, the results will be similar to the side placement discussed above. For a small wire welded

with high weld energy (relative to the wire size) the weld plasma powers through the wire. is technique melts the base

metal and joins the melted wire to the base plane. However, if the wire is larger or the energy is set to produce only a small

spot size, the wire will typically fail to be added to the base material. Instead the wire will ball and some melting of the base

material will occur, which is insufficient to add the wire.

Placing the weld electrode on top of the fill wire at

a 90deg angle from the base material surface is

typically not the preferred method of adding material.

If the wire is large compared to the energy setting,

the wire will ball due to surface tension and will not be

added to the base material.

A top electrode placement can work if the wire

diameter is small compared to the energy setting. In

this case there is enough plasma pressure to force the

molten wire onto the base material. Placement of the

electrode directly on top of the fill wire can melt the

wire into the base if the energy is sufficient, or the wire

is very small. Alternatively, it may only melt the wire

causing it to ball as shown here.

Loading...

Loading...