15

OrionWelders.com

Symptom Possible Problem Possible Solution

4 Porosity in the work-

piece

Damaged electrode with jagged

tips

Re-grind electrode

Metal may contain zinc and “boil”

during the welding process. (e.g.

white gold)

Often welding over the same location two or

three times will smooth the weld spot

Sharp electrode in a mobile

metal such as silver

Truncate the end of the electrode to help “un-

focus” the weld energy

As electrodes wear, they will become dull and result in lower quality and less attractive welds. Sharpening or changing

them out periodically is important to maintain weld consistency.

e Orion’s electrodes are made of lanthanated tungsten. e small amounts of lanthinum found in the electrodes help

the tips stay sharp and help improve weld performance. e electrodes are also double ended, meaning that either end

can be used for welding.

When swapping electrodes, use caution when touching any part internal to the stylus. With extensive use, the internal

parts and especially the electrode WILL BE HOT. Allow them to cool before attempting to change electrodes. As an added

safety precaution, it is recommended to put the Orion in Stop Mode.

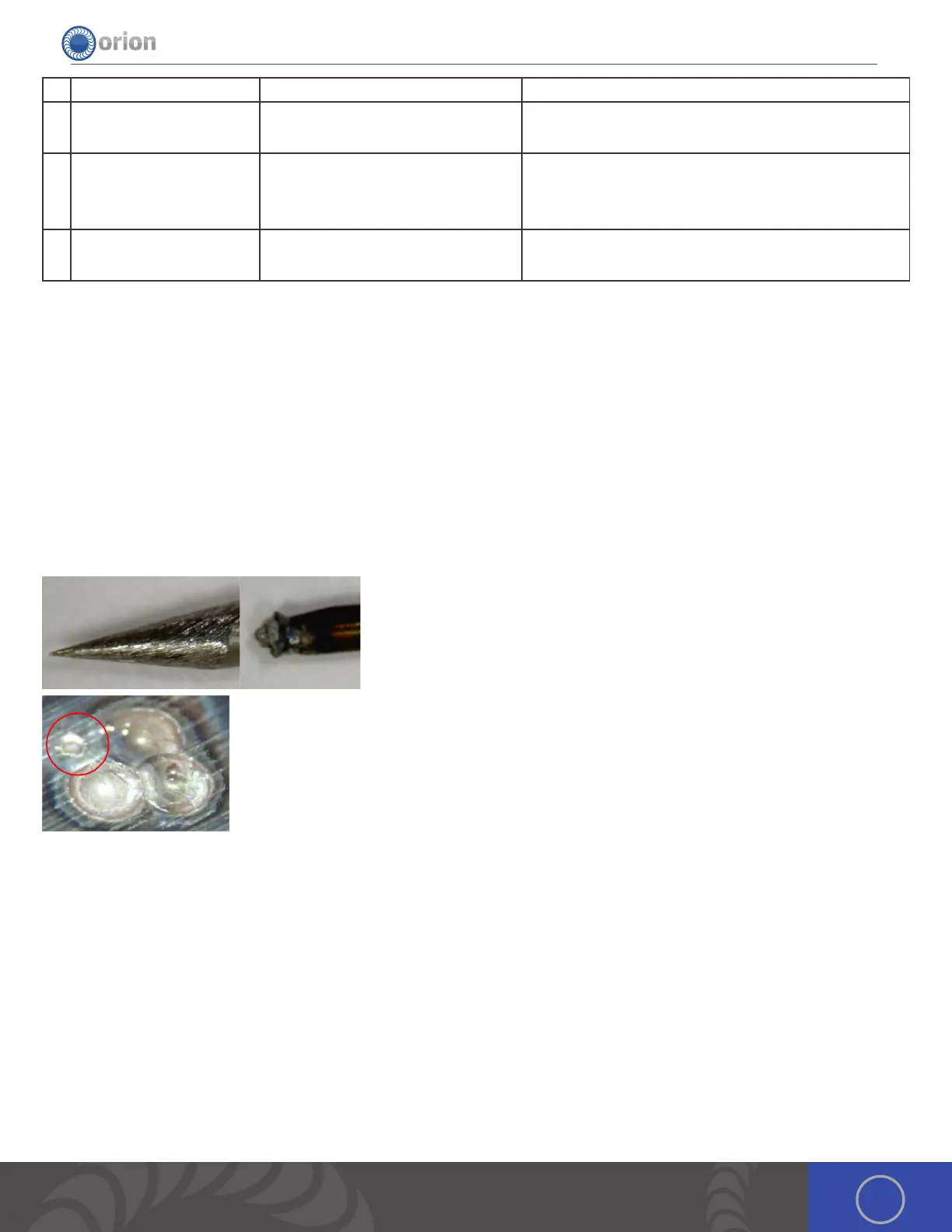

Electrode condition greatly affects energy transfer and also weld properties

(see above discussions). Left: A perfect electrode. Right: An electrode in

poor condition with metal contamination.

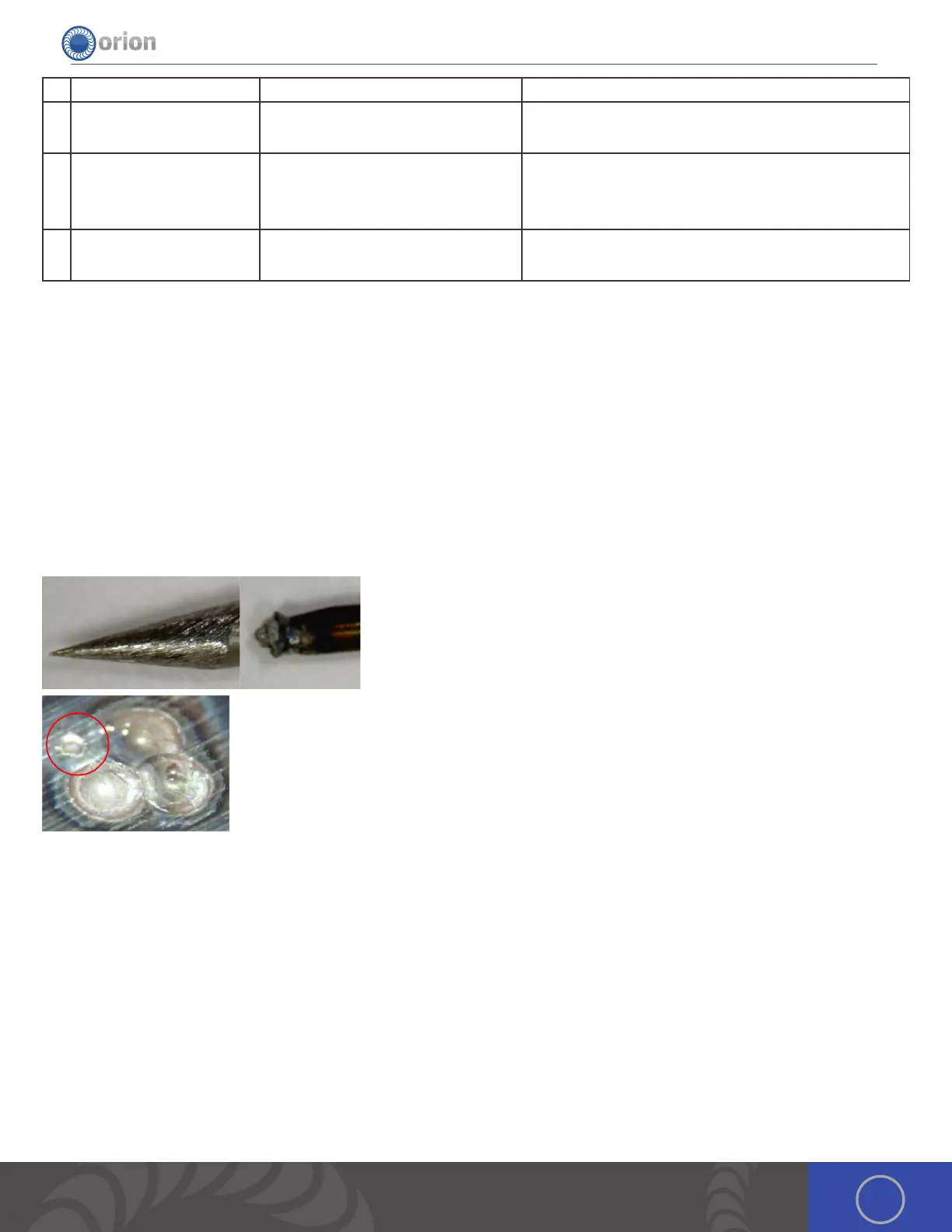

Electrode contamination can lead to small “explosions” that create craters in the workpiece. All

four welds were made at the same setting. Metal contamination on the electrode caused one

weld to create a crater.

It is recommended that you pay close attention to the electrode condition (see additional discussion). A contaminated

electrode can lead to inconsistent welds and poor arc starting. Only light pressure is needed to start the welding process,

too much pressure will interfere with the welding process, leading to electrode metal contamination and will shorten the

amount of time you can weld before re-sharpening or replacing the electrode.

Chapter 4: Techniques, Tips, & Tricks

Pulse Arc Welding: Adding Material

Typically material is added with a small “laser” wire, one weld at a time. However, there are many additional options to add

material. One for example is, instead of using small “laser wire” the Orion can weld a much larger wire or rod to fill in more

metal in a single weld.

Loading...

Loading...