Orion Pulse Arc Welding Workbook

18

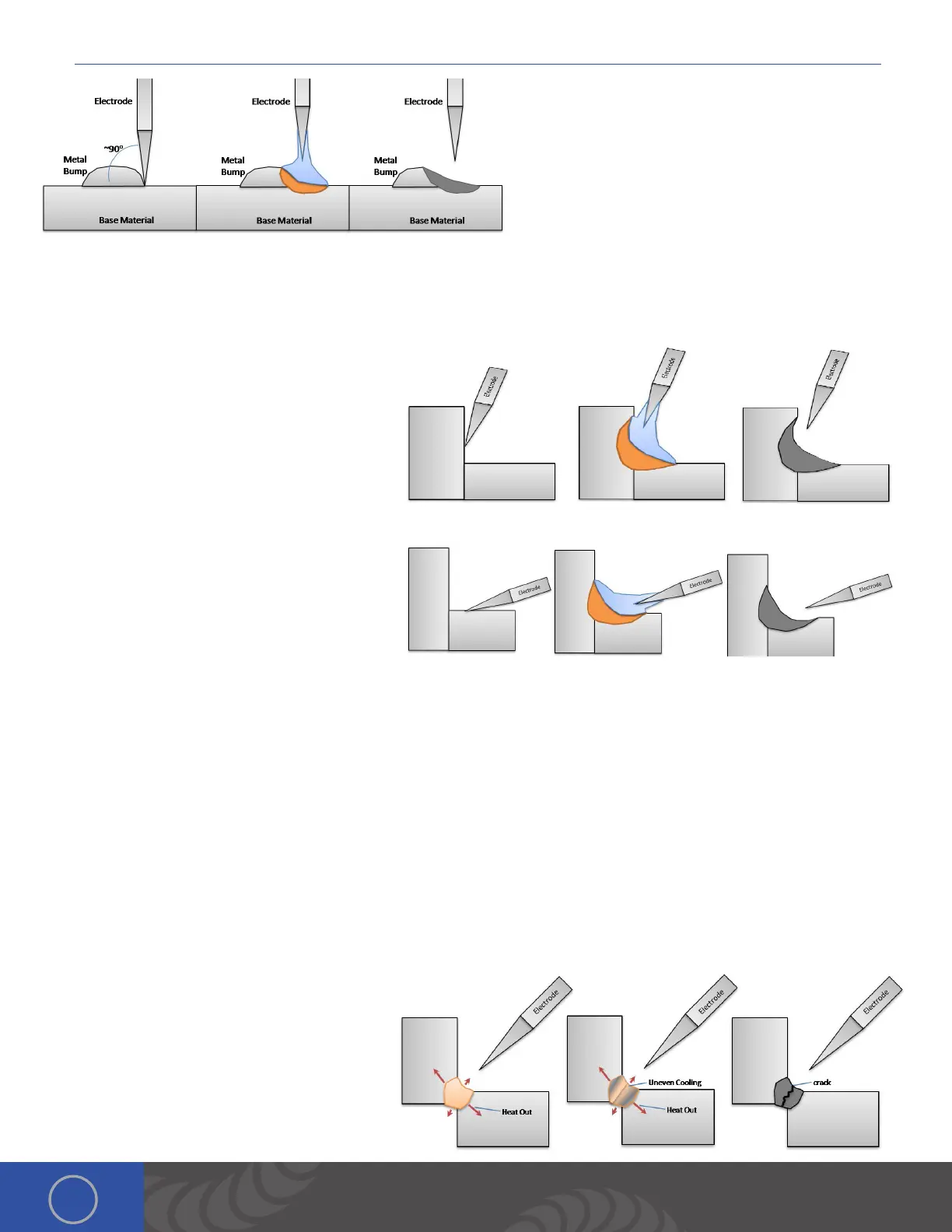

Placing the weld electrode on the edge of a bump will

smooth away the bump as surface tension spreads the

metal over the molten base material.

HANDS ON: Use your electrode with several different

materials to push metal around, or to use surface

tension to smooth a metal mound out.

Please note that various metals will react differently to pushing and surface tension smoothing. For example, silver has

a relatively low surface tension while in a liquid state. is means that the plasma push method may be more successful

than it would be with stainless steel (with a much higher surface tension). On the other hand, because of the high surface

tension of stainless steel, the surface tension smoothing method will proceed quickly.

Pushing metal is especially helpful if one of the

parts to be joined is heat sensitive. In this example

the horizontal member is more heat sensitive

or is thinner than the vertical member. Material

is pushed from the vertical member onto the

horizontal member to prevent part damage.

In this example the vertical member is more heat

sensitive or is thinner than the horizontal member.

Material is pushed from the horizontal member

onto the vertical member to prevent part damage.

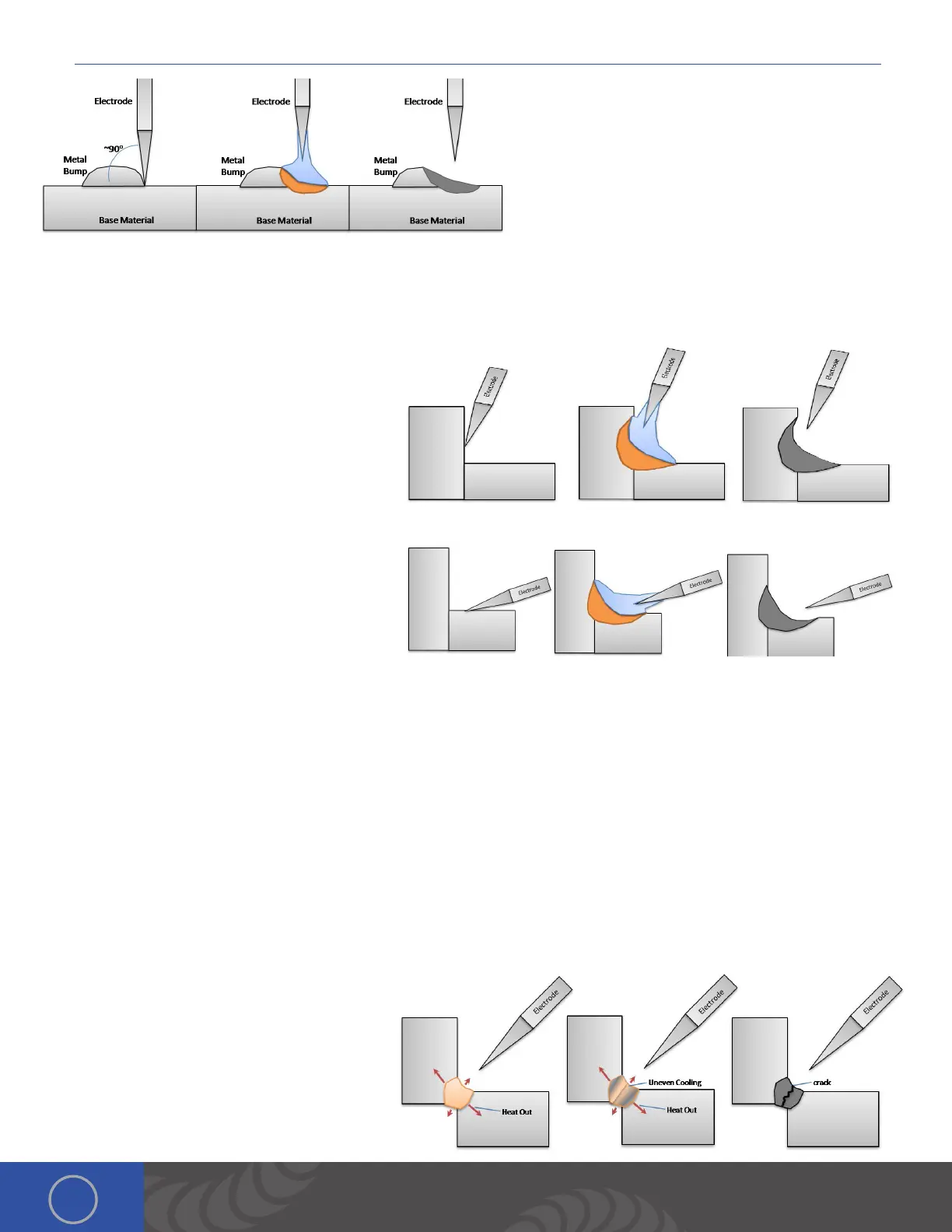

Pulse Arc Welding: Weld Cracking

Some materials are prone to crack because of their metal properties. For example, High Carbon steel, Palladium (Pd), and

some silver alloys. Why does the cracking take place? With some metals it is the new crystal structure created during the

welding process e.g. palladium and high carbon steel. However, another cracking process often called “hot cracking” can

occur when the cooling process and the resulting thermal shrinkage create high stresses in the workpiece. Hot cracking is

very geometry dependent and can be avoided by carefully considering the weld joint before welding.

IDEAS TO OVERCOME HOT CRACKING:

1. Keep joint gaps as small as possible.

2. Keep the weld length/time at its max length setting to help ramp down the heat more gradually.

Improper joint preparation or geometry can

lead to uneven weld puddle cooling. If the

puddle cools in such a way to create a hot

center section the hot section will be pulled

apart by the stresses from the cooling out

metal.

Loading...

Loading...