Orion Pulse Arc Welding Workbook

30

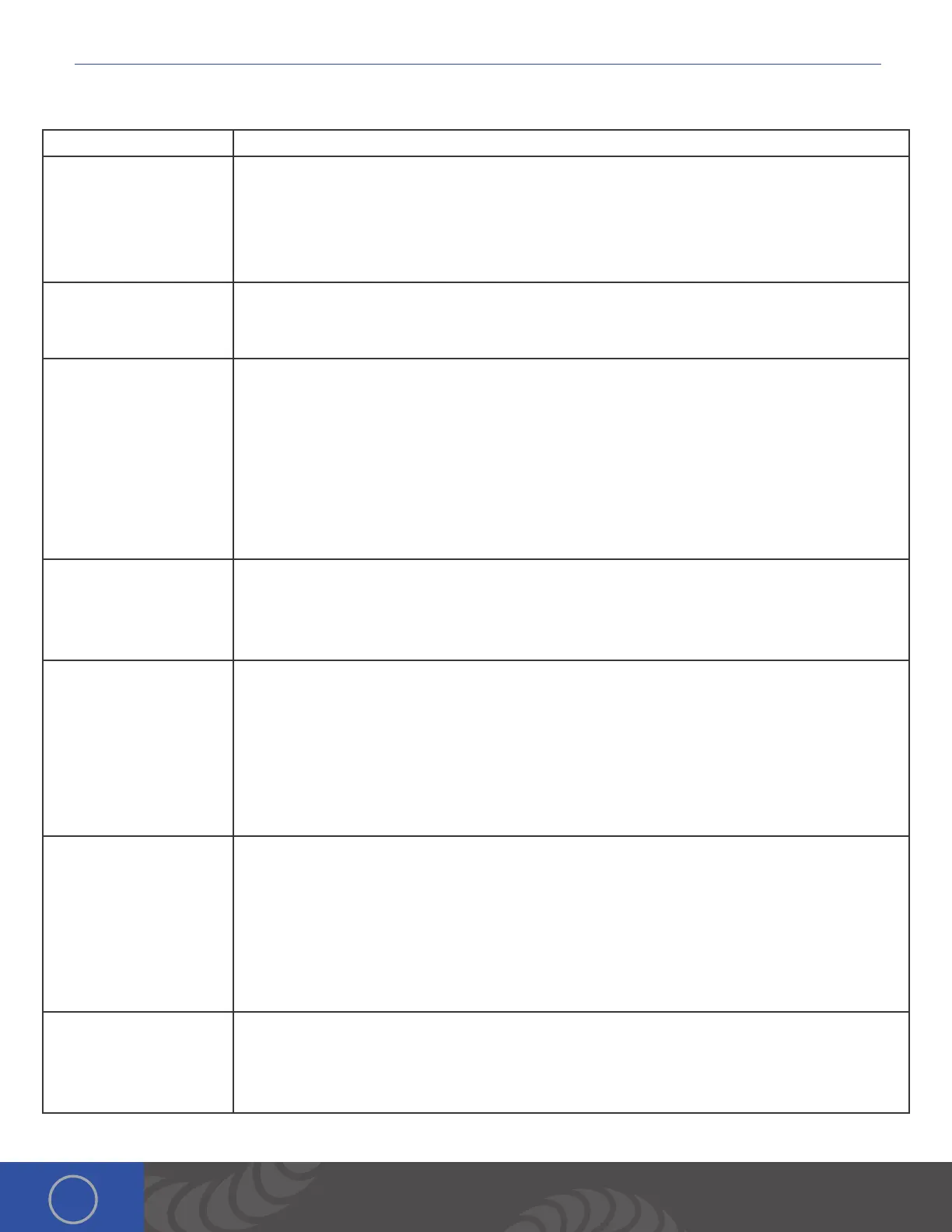

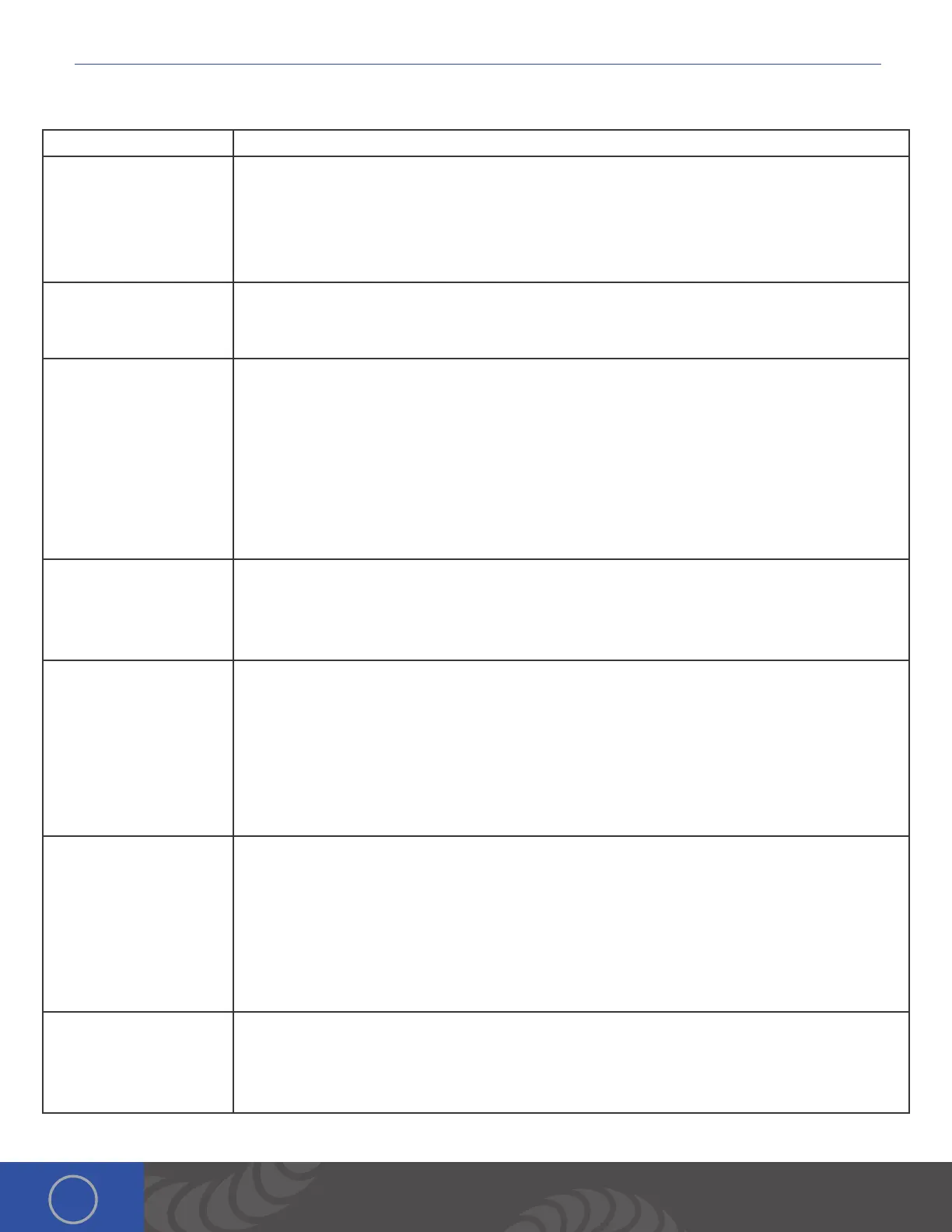

Trouble Shooting

Problem Solution(s)

My welder won’t turn

on.

•Verify that the power cord is plugged into the rear panel of the Orion and also into a

power outlet.

•Do NOT use an extension cord with the Orion.

•Check the circuit breaker for that particular power receptacle.

•Check and replace any blown fuses in the Orion’s Fuse Bay.

My electrode keeps

sticking before I even

weld.

•Clean the workpiece at the weld site.

•Clean or sharpen the electrode.

•Increase the energy slightly to add more energy to the arc.

I can trigger a weld, but

it always aborts and

does nothing.

•Hold the stylus steady so that the electrode continuously contacts the workpiece. If

contact is lost, even for an instant, the weld will abort.

•Verify that the attachment plugged into the + terminal is making constant contact with

the workpiece.

•Clean the surface of the workpiece at the weld site. Oil, carbon deposits, and other

residue can cause continuity to be lost.

•Verify that the electrode is sharp and not deformed at its tip. Replace or sharpen the

electrode as necessary.

My electrode keeps

sticking when I weld.

•Verify that the current mode is not Tack Mode.

•Hold the stylus so that there is less pressure on the electrode. Very low energy

settings will require extremely little pressure on the electrode.

•Increase the energy slightly to add more energy to the arc.

I’m set to Auto Trig-

ger (Touch Detect) but

nothing ever happens

when I touch the elec-

trode to my workpiece.

•Verify that the workpiece is clipped to, or touching, an attachment that is securely

plugged into the + Arc terminal.

•Verify that the play button is green.

•Verify that the stylus connector is completely inserted into the stylus receiver on the

front panel. Disconnect and reconnect it following the procedure given in the Setup

Instructions.

•e workpiece is not conductive and cannot be arc-welded with the Orion.

My welds look dirty or

blackened.

• Change the flow rate of the shielding gas. Between 5 -10 PSI is recommended.

• Decrease the length of exposed electrode to bring the workpiece closer to the stylus

nozzle.

• Verify that there are no gas leaks at the gas receiver on the rear panel of the Orion

and also at the stylus connector on the front panel. Note: Gas cannot leak from the

stylus connector except during a weld.

• Increase your gas post flow to ensure that welds will look cleaner.

e Orion still shows

that I have gas con-

nected even after I’ve

turned my tank off.

• Even though the tank’s valve has been shut, there may still be residual pressure in the

gas tube. After the pressure is released, the Orion will display the gas connectivity

status correctly.

Loading...

Loading...