Orion Pulse Arc Welding Workbook

6

*Remember that the weld is created only when the electrode lifts from the workpiece surface. is means that using too much

pressure will prevent a weld from taking place and will also damage your electrode.

e penetration of your weld spot depends on many different factors. However, as a rule

of thumb you can expect the penetration of the weld spot to be approximately ¼ of the

diameter of the weld spot. Factors like electrode shape and condition also effect the weld

penetration and will be discussed in more detail later.

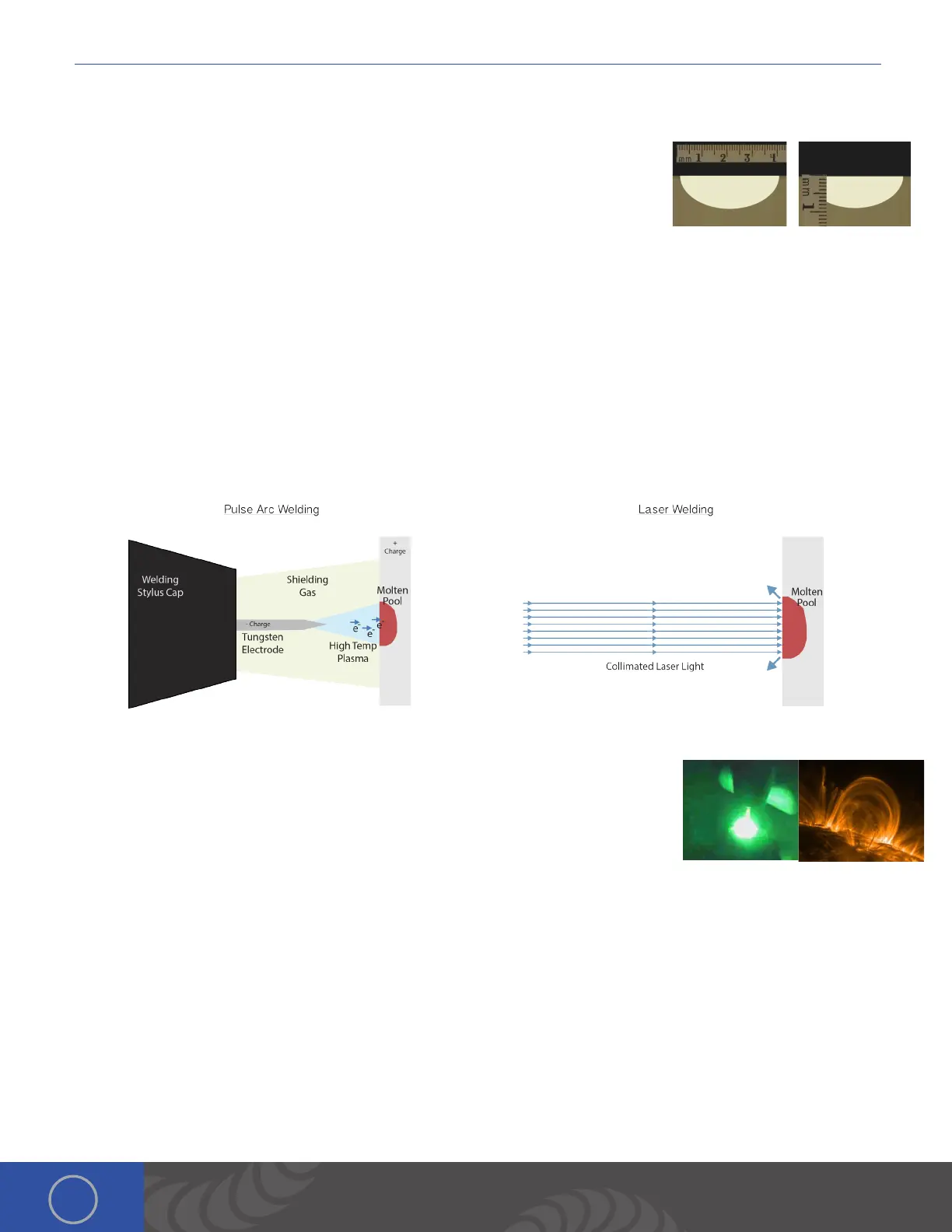

PULSE ARC VS. LASER

Laser welding and pulse arc welding technologies are designed to create high quality welds in precious and non precious

metals. Laser welding uses collimated or focused light to add energy to the metal and melt it at a single location. Pulse Arc

welding uses electricity (specifically electrons) to add energy to the workpiece and melt the metal in a spot. Although laser

welding devices are good welding tools, the Orion can perform many of the same functions of a laser and in some cases

can even perform actions that lasers cannot. For example, welding silver is difficult for laser light because of silver’s highly

reflective properties. However, the Orion does not have this limitation because electrons are electrically attracted to the

surface of silver. e Orion also has the advantage of only welding on metal. Lasers can strike precious stones or other

nonmetals and can even crack or evaporate the target. Because the Orion is electrically driven it requires a conductor, such as

a metal, to allow the welding process to take place.

e Orion welder uses the same high temperature plasma that can be found on the surface

of the sun. e sun creates this plasma via internal fusion reactions and the plasma

temperature measures about 5,500 deg C at the sun’s surface. e Orion creates it’s plasma

via electrical discharge and can generate temperatures of 5,500 – 8,000 deg C in very

controlled, small bursts.

START WELDING

To become an expert and to really learn how to maximize the capabilities of the Orion, we recommend that you dedicate time

for real hands on experience. We recommend that you read and complete the following sections while you are in front of your

Orion. Your Orion is very easy-to-use and you will be making quality welds within minutes. e purpose of this section is to

help you to better understand some of the fundamental welding principles, to utilize all of the functions of your Orion, and to

adapt this knowledge to specific applications.

As you can see from this example, Orion welding machines offer a lot of energy. Higher energies are perfect for larger/thicker

pieces, deeper weld penetration and for welding highly conductive metals like silver.

Loading...

Loading...