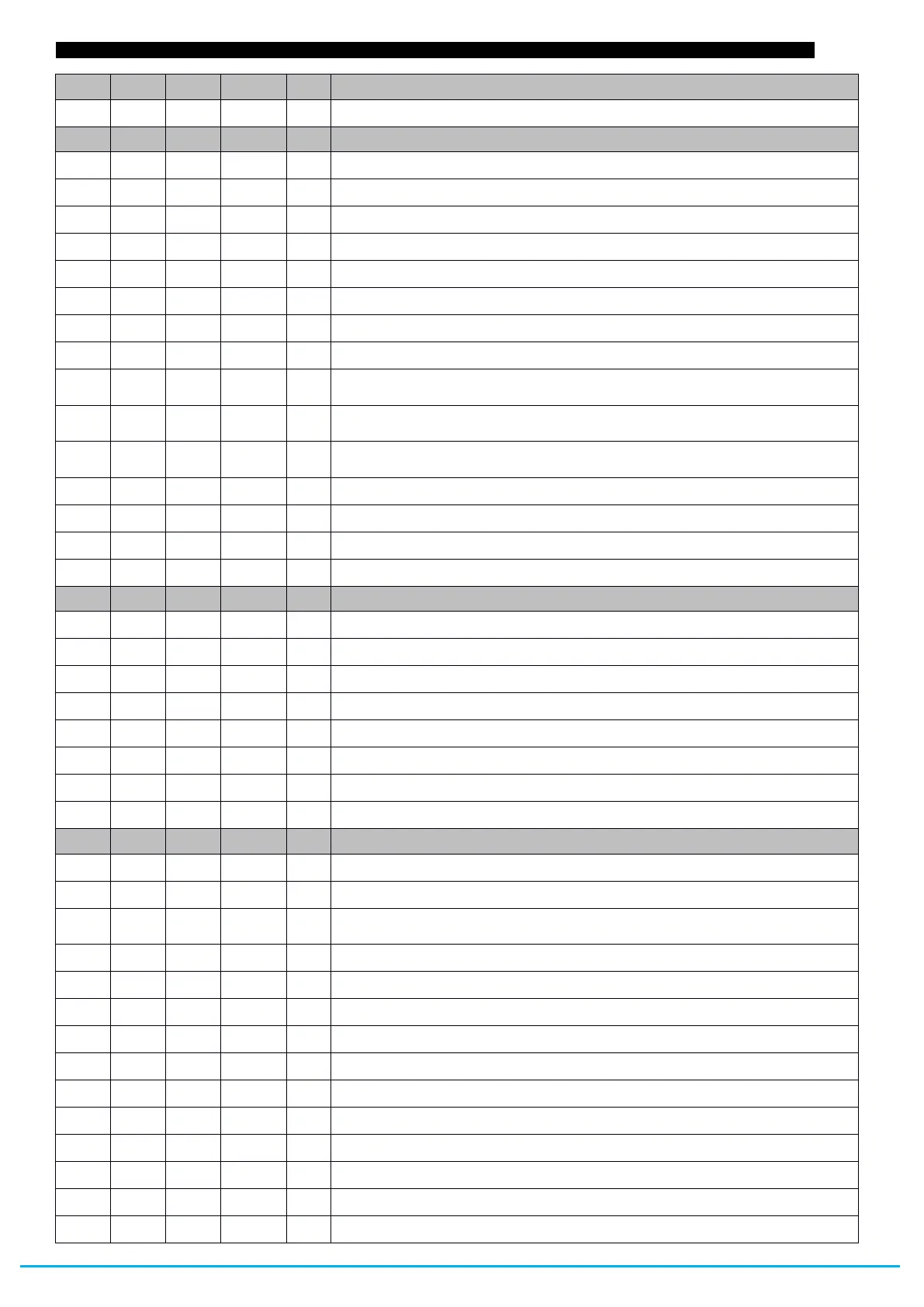

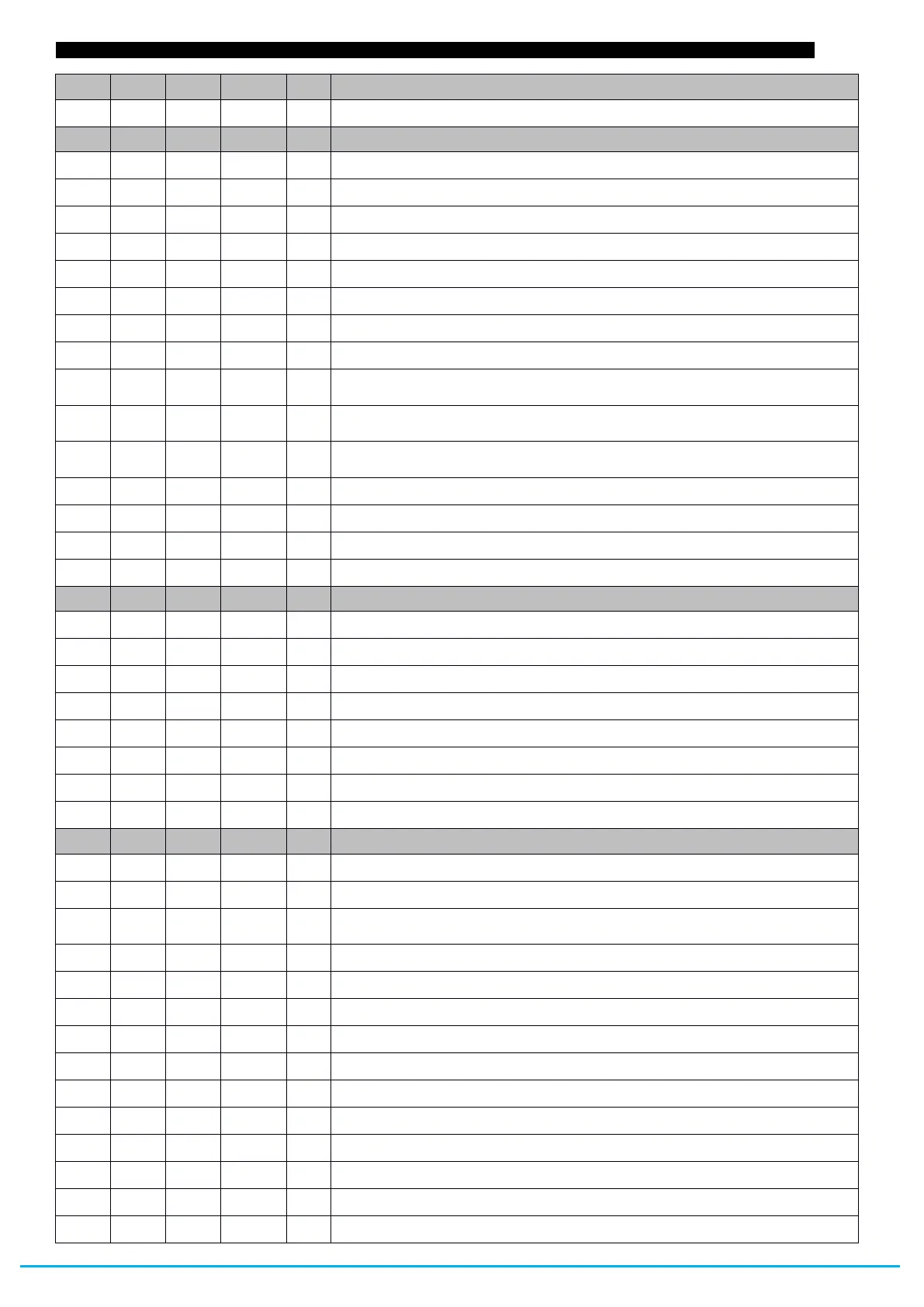

OSAKA – SMART BOX – Simple Manual – v1.1 – Page 6

11 – PARAMETER LIST _

Room temperature calibration (if P4=0,1,2,3), air input temperature calibration (if P4=4)

Evaporator’s temperature calibration.

Auxiliary temperature calibration.

Evaporation’s temperature calibration.

Low pressure calibration.

Probe type (0 = PTC; 1 = NTC; 2 = PT100).

Decimal point for temperature (only in ºC).

Temperature’s unit of measurement (0 = °C; 1 = °F). (3)

Function of the evaporator’s temperature probe (0 = not used; 1 = evaporator’s fan probe and defrosting; 2

= evaporator’s fan probe).

Function of the auxiliary probe 0 = not used; 1 = condenser’s temperature; 2 = critical temperature;3 =

temperature of the evaporator 2; 4 = air output temperature).

Visualized temperature during the normal operation ((0 = room temperature or CPT temperature; 1 =

regulation set point; 2 = evaporator’s temperature; 3 = auxiliary temperature; 4 = air input temperature).

Percentage of the air input temperature in order to calculate the CPT temperature. (4)

Visualization delay in temperature changes.

Low pressure transducer’s inferior limit.

Low pressure transducer’s superior limit.

Regulation differential (hysteresis), or dead zone differential (according to the number of compressors). (6)

Minimal limit of the regulation Set Point.

Maximal limit of the regulation Set Point.

Lock the modification of the regulation Set Point (0 = NO; 1 = YES;).

Regulation Set Point increase during the “energy saving” operation mode.

Regulation Set Point decrease during the “turbo” operation mode.

Duration of the “turbo” operation mode.

Dead-band type or regulation differential type (0 = asymmetrical; 1 = symmetrical)

ELECTRONIC EXPANSION VALVE (SMART BOX VEX MODEL)

Superior temperature limit of the evaporation for a high superheating alarm (code “HSH). (7)

Inferior temperature limit of the evaporation in order to activate the low pressure operation mode (the valve

opens entirely; code “LOP”). (7)

Proportional band in PID control.

Integral Time in PID control.

Derivation time in PID control.

Valve’s opening percentage in manual mode (-1 = Automatic regulation and superheating alarm available).

Opening percentage of the valve during the hot gas defrosting.

Inferior limit of low pressure in order to stop the compressor during the liquid injection to the evaporator.

High superheating alarm delay (code “HSH”).

Enable the low pressure alarm (code “LP”; 1 = YES)

Inferior limit in order activate the minimal low pressure alarm (code “LP”). (8)

Minimal low pressure alarm delay (code “LP”).

Loading...

Loading...