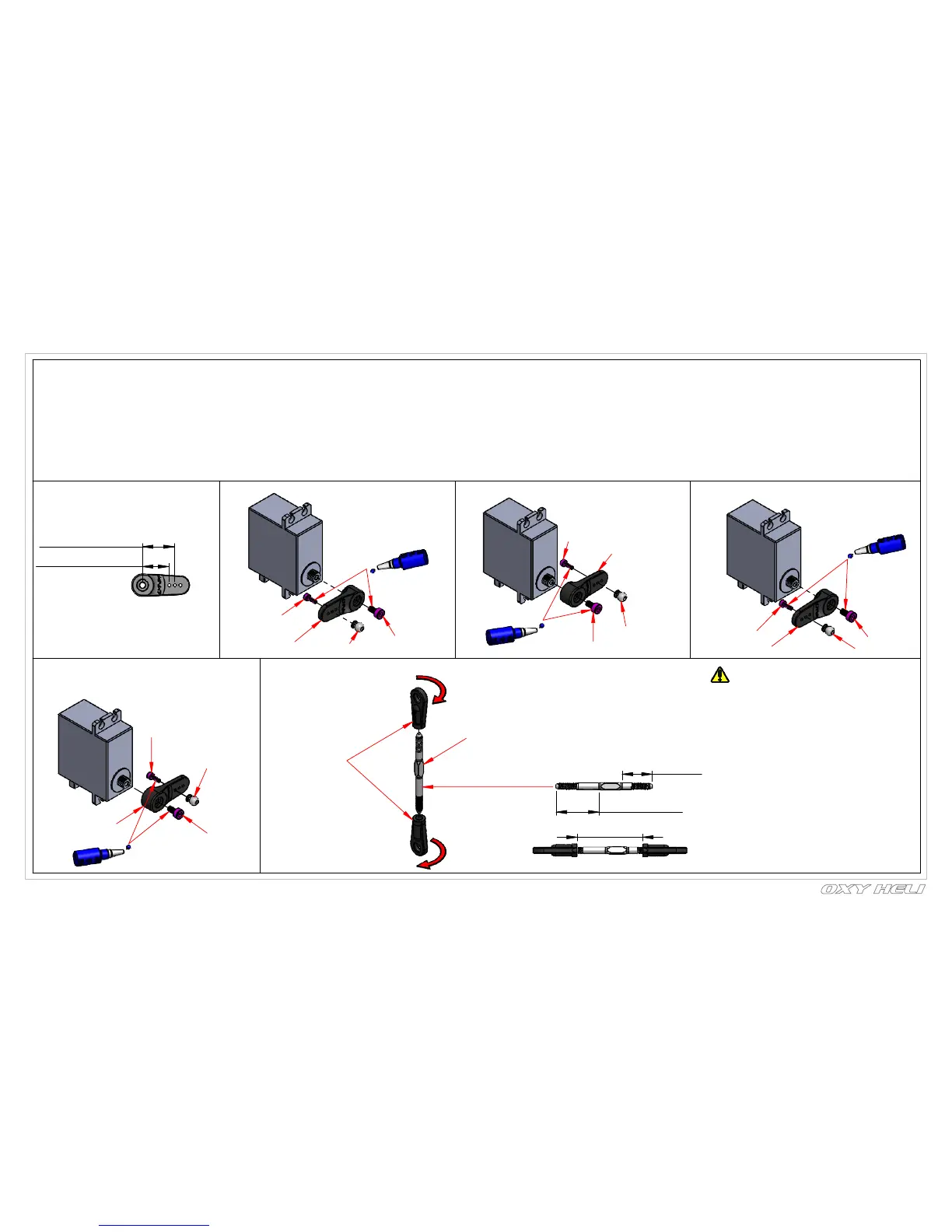

17.50( for Cyclic )

14.50 ( for Tail Servo )

M2x6 Hex Cap Screw

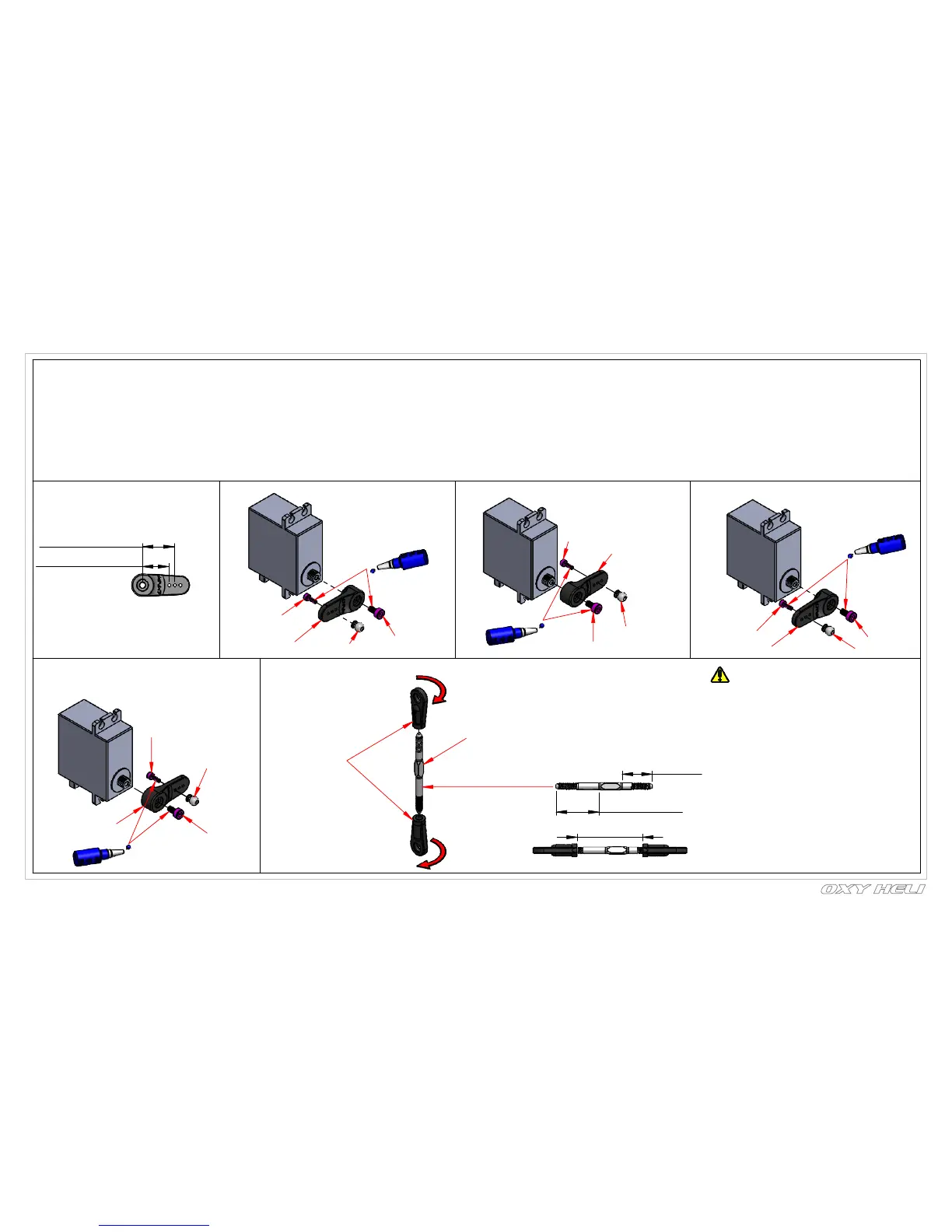

Ref 30.50

14mm

Clock Wire

20mm

Counter Clock Wire

-

You should now do some initial setup of your FBL unit and servos.

- We recommend you select a new model in your transmitter, and reset your FBL unit and start with a clean setup in it as well.

- After binding your transmitter to the receiver system used with the FBL unit, work your way through the FBL setup instructions to the point

you plug in your servos.

- Now set your collective stick in the middle position, and position the servo arms as close to the correct positions you can on each servo

see the following pages for arm orientations on the various servos.

- Next confirm the servos work in the correct direction, then return the collective stick to the center position.

- Now use your FBL unit to trim the servos so the arms are exactly horizontal (see pictures below).

- This procedure varies between units. Carefully label the position of the servos, then proceed with the installation of the servos as shown.

Chapter 14: Servo & Servo Rod Prepareration

Linkage Ball Position

Servo Screw

Servo Screw

Loctite 243

Servo Arm

Linkage Ball

M2x6 Hex Cap Screw

M2x6 Hex

Cap Screw

Servo Arm

Linkage Ball

Servo Screw

Loctite 243

Servo Arm

M2x6 Hex Cap Screw

Servo Screw

Loctite 243

Linkage Ball

Servo Arm

Linkage Ball

It is really important the servo rods screw onto

the linkages the same amount. The Metal Rod

have one side clock wire thread and one side

have counter clock wire thread

Servo Rod Assembly ( 3pcs)

M3x45 Turnbuckle Rod

Plastic

Linkage Ball

Tail Servo

Cylic Front Right Servo

Cylic Front Left Servo

Cylic Rear Servo

page 37

Loading...

Loading...