Section 2: Pall PCM500 and PCM500W

Fluid Cleanliness Monitors

2.1 Inspection and Packaging

The PCM500 is shipped in a transportation

case. Use this case for re-shipping the PCM.

Visually inspect the case for signs of external

damage that may have occurred during

shipping and bring any damage to the

attention of the shipper.

Inspect the interior of the case for damage to

the contents as listed below. Compare the

contents of the case with the shipping papers

to assure all the content is present. If any

items are missing, contact Pall or an

approved agent.

The PCM500 package comprises of:

• Integrated PCM500 series monitor with

sample hoses

• Power supply unit

• Mains power lead

• PCM500 to PC communications cable

• PCM500 series Operating Instructions on

CD ROM

• PCM500 series Quick Reference Guide

• Fluid Sampling stalk

• High Pressure test point connector

(Choice of Imperial, Minimess or NPT)

• Certificate of Conformity

• Certificate of Calibration Verification

• Packing note checklist

The instruments’ specific serial number and

calibration/service record sheet is also

included. It is important to keep this in a safe

place and return them with the unit for future

annual service requirements.

Caution: Health and Safety.

Ensure there is adequate

lighting to operate the

equipment.

Observe local regulations for

factory use.

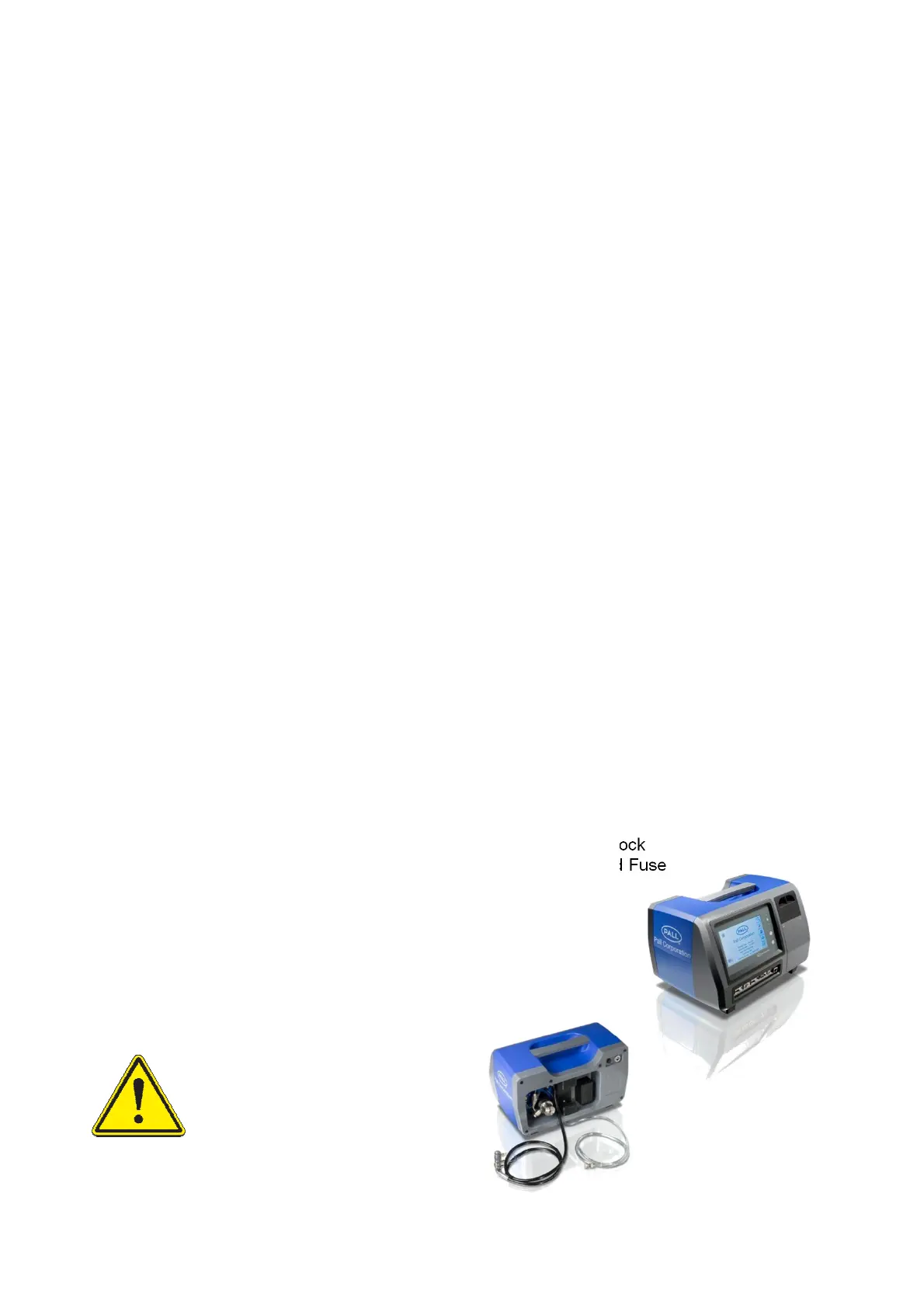

Section 3: Pall PCM500 and PCM500W

Fluid Cleanliness Monitors

3.1 Description of the Monitor

The PCM500 is designed and built for light

Industrial use while maintaining aesthetic

and user friendly ergonomics. See section 1

for full specification. The materials are

selected to meet the various fluid and

environmental conditions that the PCM500 is

likely to be subjected during operation.

As a self-contained unit, including sampling

hose and adapters, the user is able to

connect the PCM500 on-line or sample fluid

directly from a system reservoir without

breaking lines thereby avoiding extraneous

contamination.

The PCM500 cleanliness monitor provides

numerous display functions to assist the user

at all stages of operation and provides

function codes to warn of any problems with

both the PCM500 and system fluid.

1. HMI (display/controller)

2. Communication Ports

3. Robust case with carry handle.

4. Integral 12VDC battery

5. Printer storage compartment

6. Last Chance Filter Housing

7. Hose Storage

8. Mesh Screen block

9. Power input and Fuse

❶

❺

❹

❸

❷

10

❾

❽

❼

❻

Loading...

Loading...