5. When installing or transferring an AC, follow the instructions in

the installation instructions carefully. Incorrect installation can

result in an abnormal refrigeration cycle or water leakage, electric

shock, fire, etc.

6. Do not perform any alterations on the AC unit under any

circumstances. Have all repair work done by a specialist.

Incorrect repairs can result in an water leakage, electric shock,

fire, etc.

10.2. TOOL FOR INSTALLING / SERVICING REFRIGERANT PIPING

10.2.1. Necessary Tools

In order to prevent an R410A AC from mistakenly being charged with any other refrigerant, the

diameter of the 3-way valve service port on the outdoor unit has been changed. Also, to

increase its ability to withstand pressure, the opposing dimensionshave been changed for the

refrigerant pipe flaring size and flare nut. Accordingly, when installing or servicing refrigerant

piping, you must have both the R410A and ordinary tools listed below.

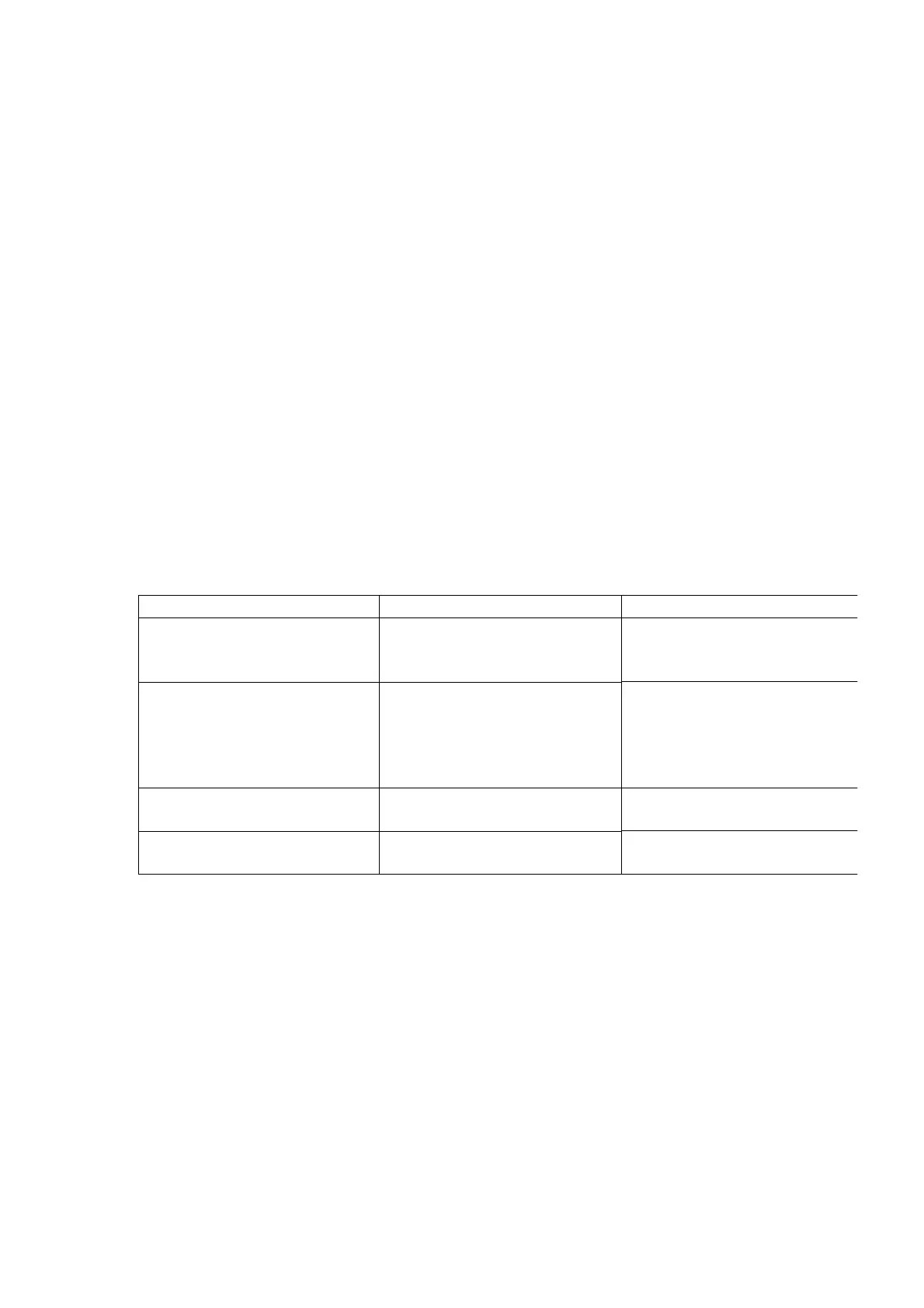

Table 3 Tools for installation, transferring or replacement

Type of work Ordinary tools R410A tools

Flaring Flaring tool (clutch type), pipe

cutter, reamer

Copper pipe gauge for

clearance Adjustment, flaring

tool (clutch type)*1)

Bending, connecting pipes Torque wrench(nominal

diameter 1/4, 3/8,1/2) Fixed

spanner(opposing sides 12

mm, 17 mm, 19 mm)Adjustable

wrench, Spring bender

Air purging Vacuum pumpHexagonal

wrench(opposing sides 4 mm)

Manifold gauge, charging

hose,vacuum pump adaptor

Gas leak inspection Gas leak inspection fluid or

soapy water

Electric gas leak detector for

HFC refrigerant*2)

*1) You can use the conventional (R22) flaring tool. If you need to buy a new tool, buy the R410A

type.

*2) Use when it is necessary to detect small gas leaks.

For other installation work, you should have the usual tools, such as screwdrivers (+,-), a metal-

cutting saw, an electrical drill, a hole core drill (65 or 70 dia.), a tape measure, a level, a

thermometer, a clamp meter, an insulationtester, a voltmeter, etc.

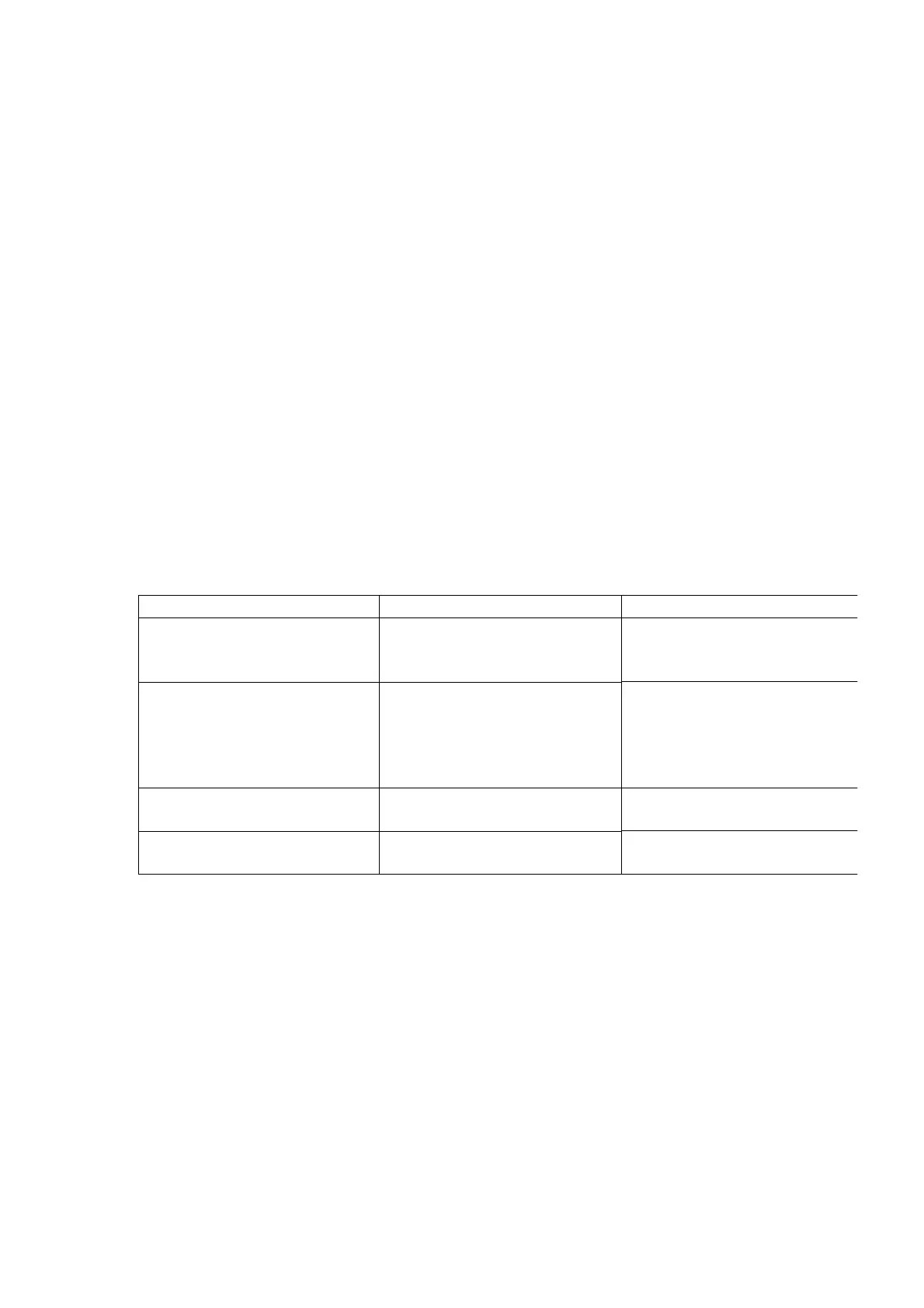

Table 4 Tools for serving

Loading...

Loading...