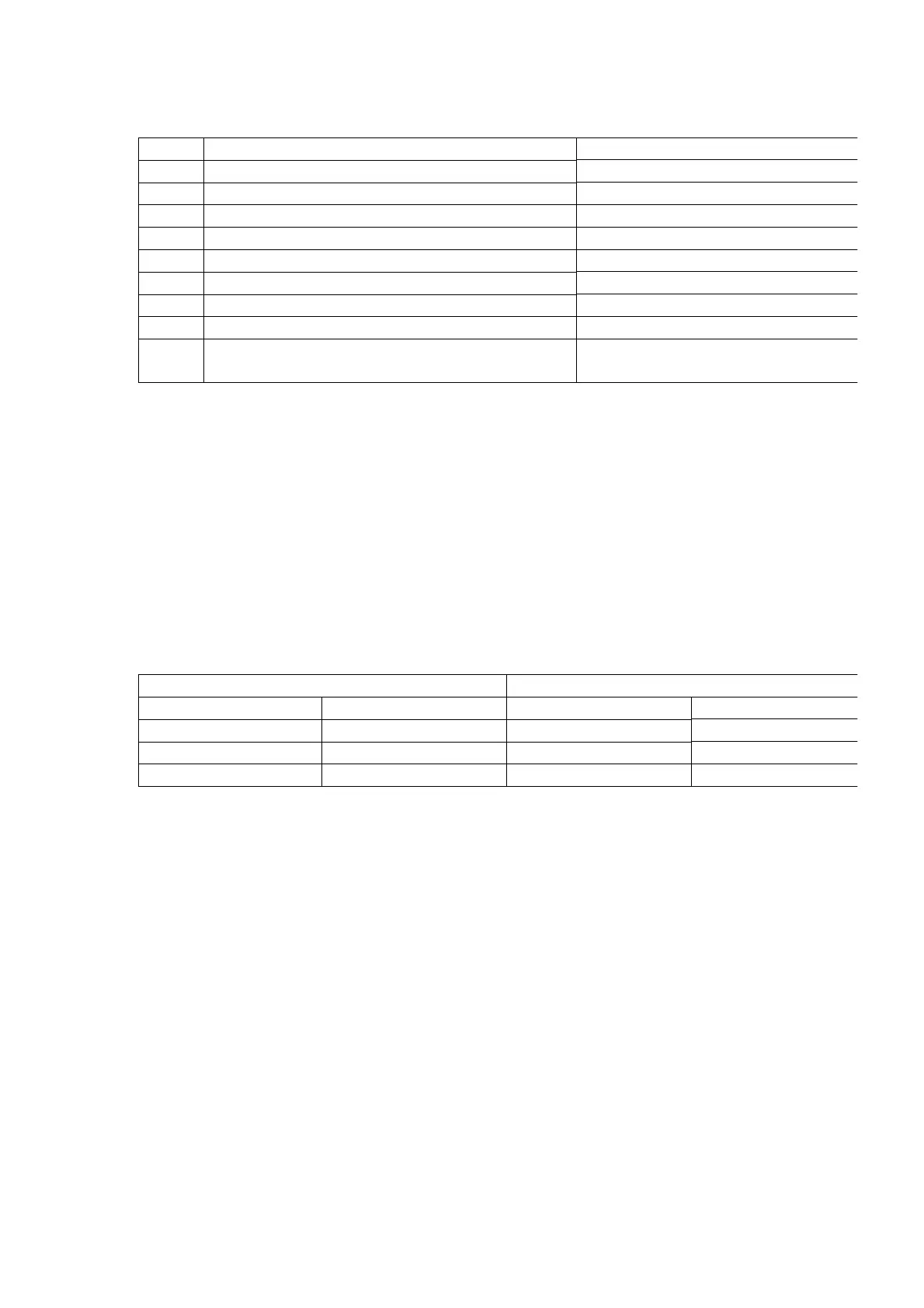

R410A tools Usable for R22 models

(1) Copper tube gauge for clearance adjustment OK

(2) Flaring tool (clutch type) OK

(3) Manifold gauge NG

(4) Charging hose NG

(5) Vacuum pump adaptor OK

(6) Electric gas leak detector for HFC refrigerant NG

(7) Electronic scale for refrigerant charging OK

(8) Refrigerant cylinder NG

(9) Charging orifice and packing for refrigerant

cylinder

NG

10.3. REFRIGERANT PIPING WORK

10.3.1. Piping Materials

It is recommended that you use copper and copper alloy jointless pipes with a maximum oil

adherence of 40 mg/10m. Do not used pipes that are crushed, deformed, or discolored

(especially the inside surface). If these inferior pipes are used,impurities may clog the

expansion valves or capillaries. / Because the pressure of ACs using R410A is higher than

those using R22, it is essential that you select materials that are appropriate for these

standards. / The thickness of the copper tubingused for R410A is shown in Table 10. Please be

aware that tubing with a thickness of only 0.7 mm is also available on the market, but this

should never be used.

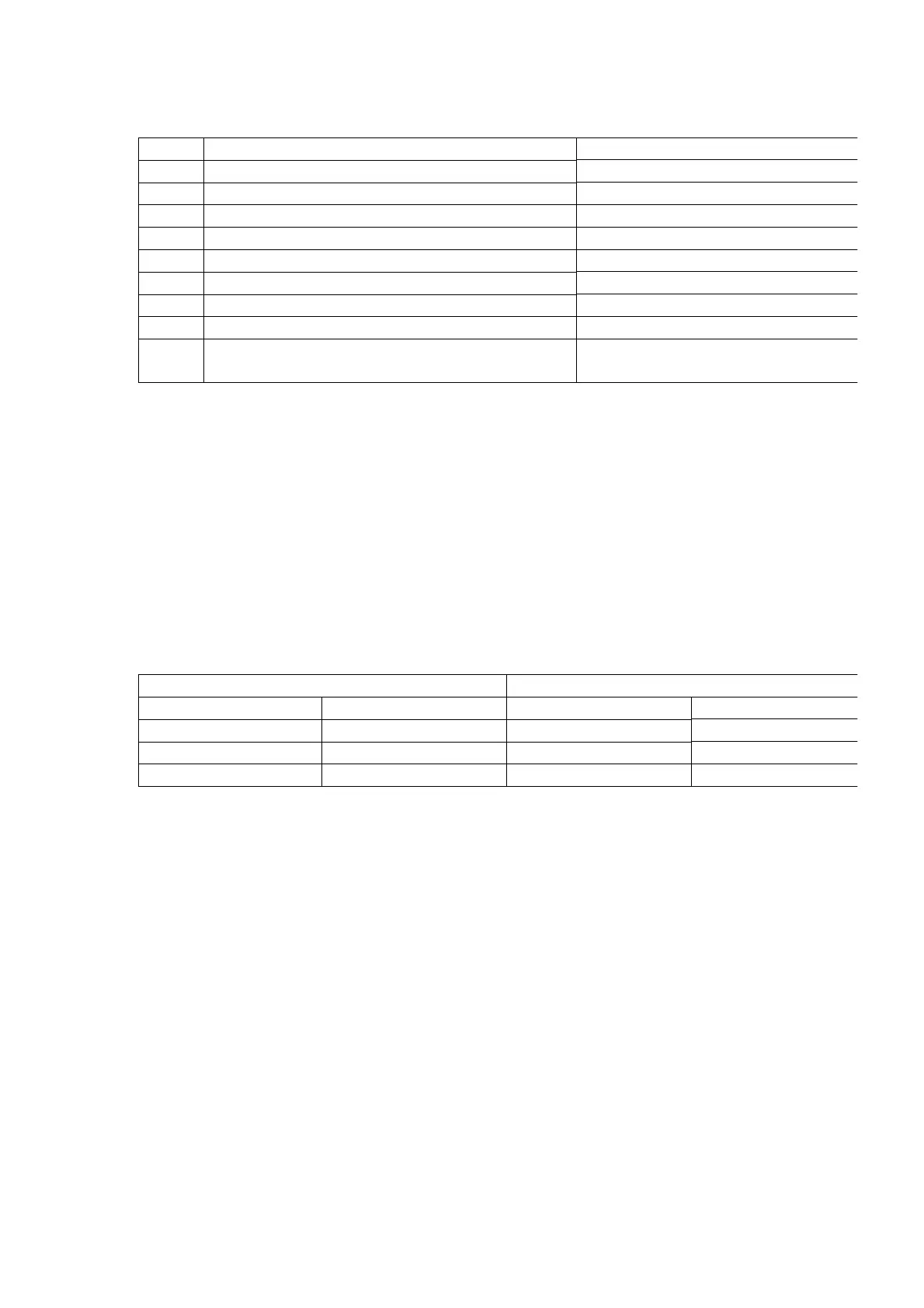

Table 10 Difference between R410A and conventional copper tube

Soft pipe Thickness (mm)

Nominal diameter Outside diameter (mm) R410A (Reference) R22

1/4 6.35 0.80 0.80

3/8 9.52 0.80 0.80

1/2 12.7 0.80 0.80

10.3.2. Processing and Connecting Piping Materials

When working with refrigerant piping, the following points must be carefully observed: no

moisture od dust must be allowed to enter the piping, and there must be no refrigerant leaks.

1. Procedure and precautions for flaring work

A. Cut the pipe / Use a pipe cutter, and cut slowly so the pipe will

not be deformed.

B. Remove burrs and clean shavings from the cut surface / If the

shape of the pipe end is poor after removing burrs, or if

shavings adhere to the flared area, it may lead to refrigerant

leaks. / To prevent this, turn the cut surface downwardand

remove burrs, then clean the surface, carefully.

C. Insert the flare nut (be sure to used the same nut that is used

on the AC unit)

Loading...

Loading...