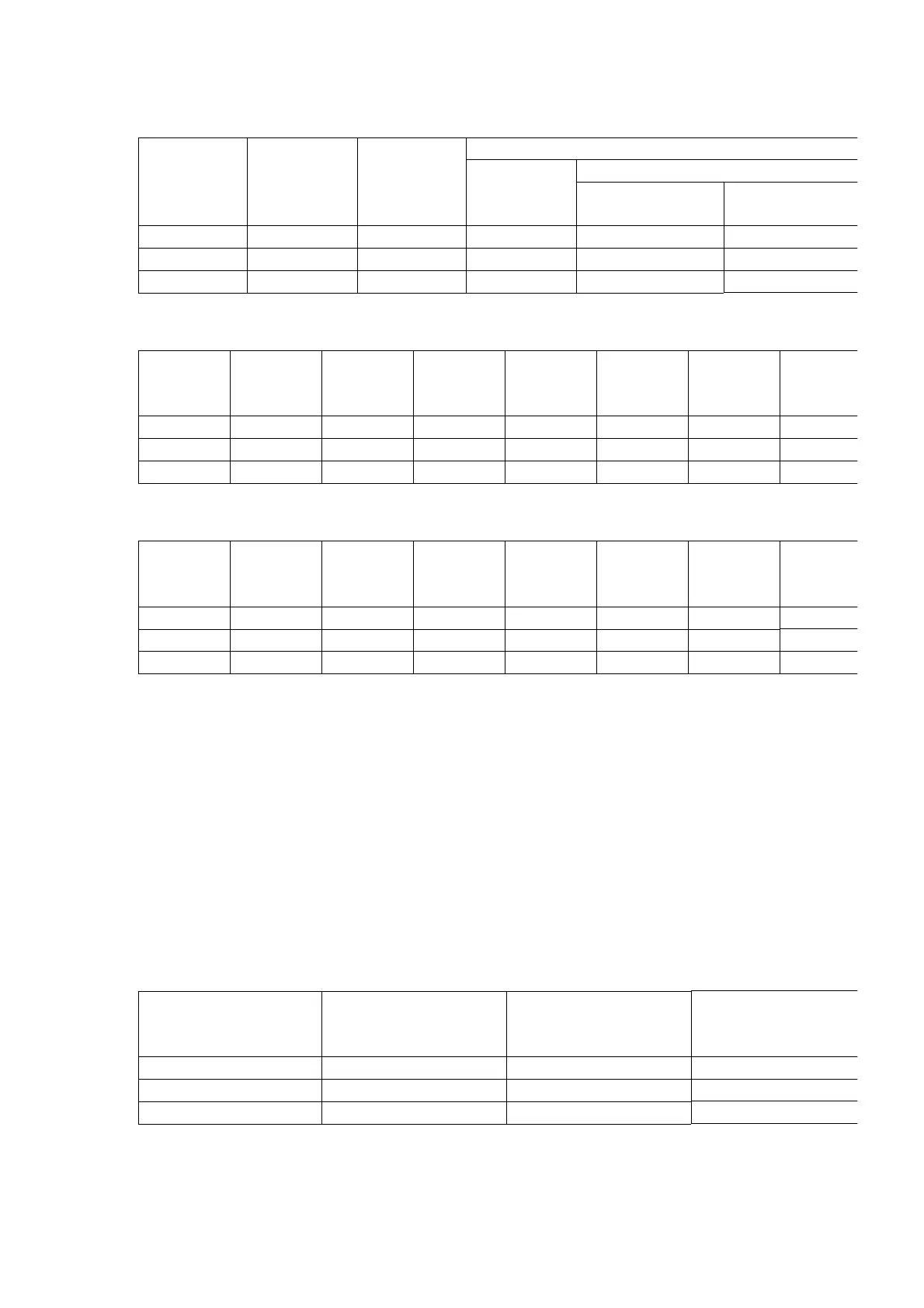

Nominal

diameter

Outside

diameter

(mm)

Wall

thickness

(mm)

A (mm)

R410A flaring

tool, clutch

type

Conventional flaring tool

Clutch type Wing-nut type

1/4 6.35 0.8 0 - 0.5 0.5 - 1.0 1.0 - 1.5

3/8 9.52 0.8 0 - 0.5 0.5 - 1.0 1.0 - 1.5

1/2 12.70 0.8 0 - 0.5 0.5 - 1.0 1.5 - 2.0

Table 13 R410A flaring and flare nut dimensions Unit: mm

Nominal

diameter

Outside

diameter

(mm)

Wall

thickness

(mm)

A +0, -0.4 B

dimension

C

dimension

D

dimension

Flare

width

1/4 6.35 0.8 9.1 9.2 6.5 13 17

3/8 9.52 0.8 13.2 13.5 9.7 20 22

1/2 12.70 0.8 16.6 16.0 12.9 23 26

Table 14 R410A flaring and flare nut dimensions Unit: mm

Nominal

diameter

Outside

diameter

(mm)

Wall

thickness

(mm)

A +0, -0.4 B

dimension

C

dimension

D

dimension

Flare

width

1/4 6.35 0.8 9.0 9.2 6.5 13 17

3/8 9.52 0.8 13.0 13.5 9.7 20 22

1/2 12.70 0.8 16.2 16.0 12.9 20 24

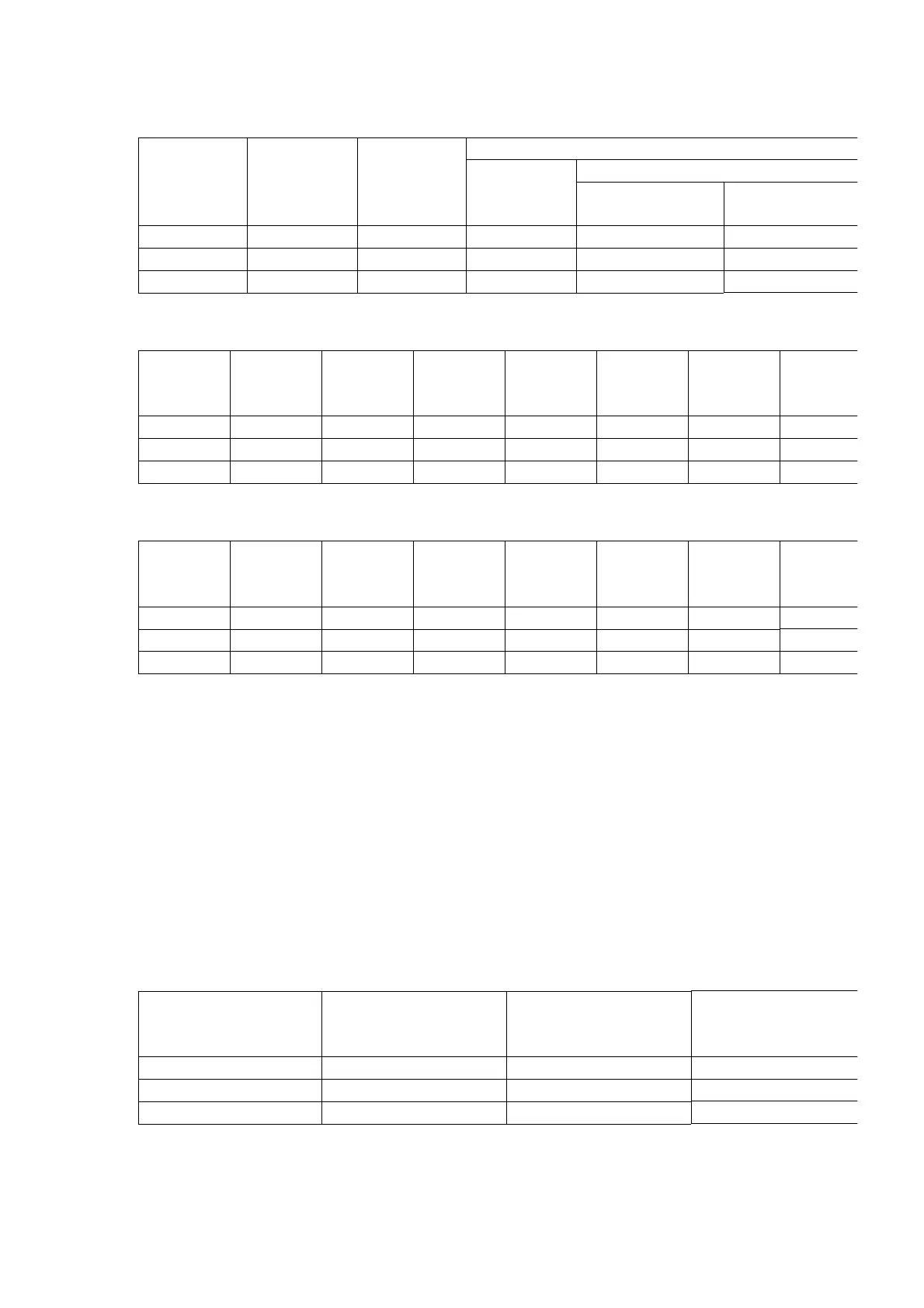

2. Procedure and precautions for flare connection

A. Check to make sure there are no scratches, dust, etc., on the

flare and union.

B. Align the flared surface with the axial center of the union.

C. Use a torque wrench, and tighten to the specified torque. The

tightening torque for R410A is the same as the conventional

torque value for R22. Be careful, because if the torque is too

weak, it may lead to a gas leak. If it is too strong, itmay split the

flare nut or make it impossible to remove the flare nut.

Table 15 R410A tightening torque

Nominal

diameter

Outside

diameter (mm)

Tightening torque

N.m (kgf.cm)

Torque wrench

tightening torque

N.m (kgf.cm)

1/4 6.35 14 - 18 (140 - 180) 18 (180)

3/8 9.52 33 - 42 (330 -420) 42 (420)

1/2 12.70 55 (550) 55 (550)

Loading...

Loading...