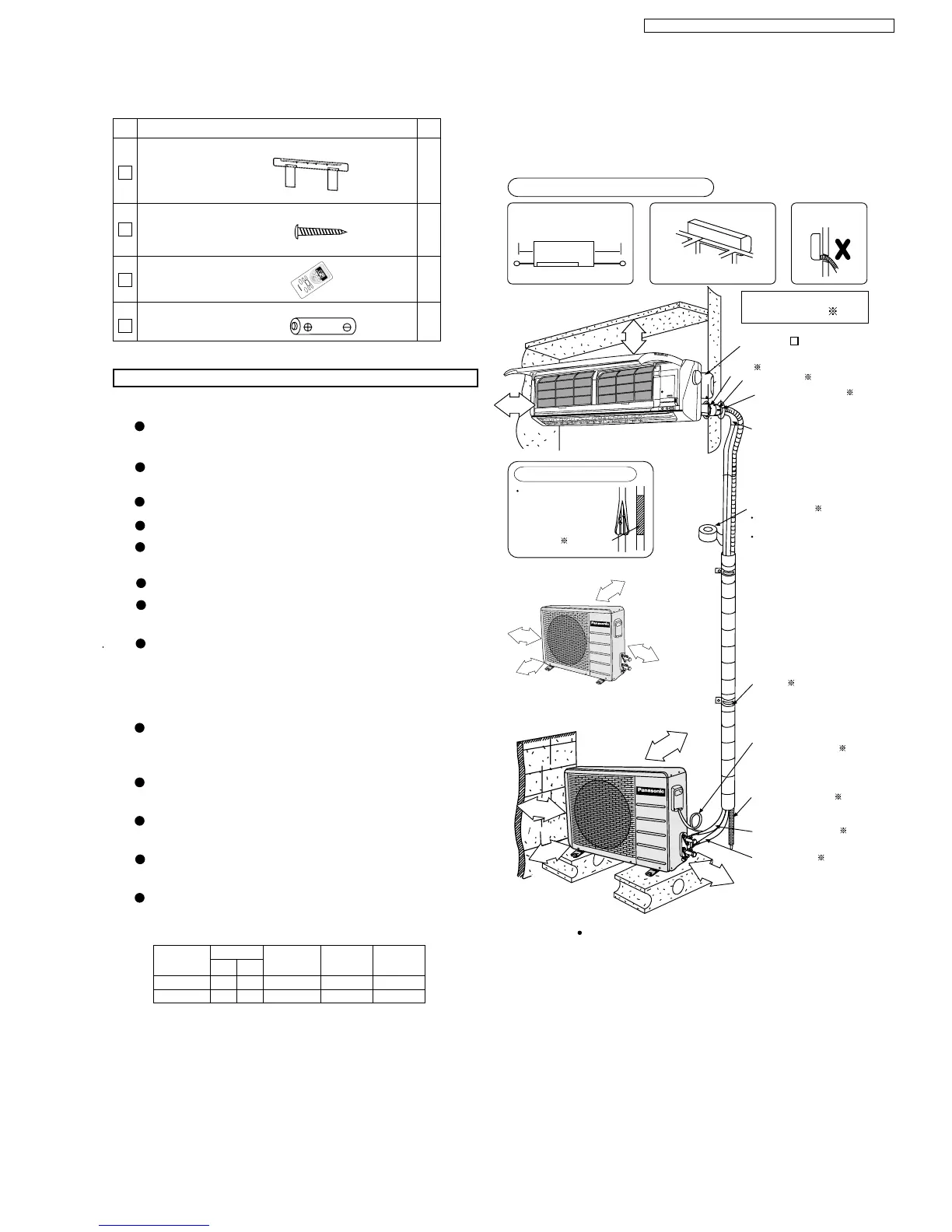

SELECT THE BEST LOCATION

INDOOR UNIT

There should not be any heat source or steam near the

unit.

There should not be any obstacles blocking the air

circulation.

A place where air circulation in the room is good.

A place where drainage can be easily done.

A place where noise prevention is taken into

consideration.

Do not install the unit near the door way.

Ensure the spaces indicated by arrows from the wall,

ceiling, fence or other obstacles.

Recommended installation height for indoor unit

shall

be

at least 2.5 m.

OUTDOOR UNIT

If an awning is built over the unit to prevent direct

sunlight or rain, be careful that heat radiation from the

condenser is not obstructed.

There should not be any animal or plant which could

be

affected by hot air discharged.

Keep the spaces indicated by arrows from wall, ceiling,

fence or other obstacles.

Do not place any obstacles which may cause a short

circuit of the discharged air.

If piping length is over the commo n length, additional

refrigerant should be added as shown in the table.

Indoor/Outdoor Unit Installation Diagram

-27-

Attached accessories.

No. Accessories part Qty.

1

2

3

4

Installation plate

Installation plate fixing

screw

Remote control

Battery

1

5

1

2

*

h

r

DE

L

A

Y

O

F

F

O

N

A

U

T

O

A

U

T

O

F

A

N

S

P

E

E

D

A

IR

S

W

I

N

G

MO

D

ET

E

M

P

O

F

F/O

N

T

IM

E

R

O

N

S

E

T

A

I

R

SW

I

N

G

O

F

F

C

A

N

C

EL

F

A

N

SP

E

ED

A

U

T

O

C

O

OL

D

R

Y

FA

N

O

F

F

S

T

D

Model

PC9DKV

PC12DKV

Piping size

Max. Piping

Length

(m)

7

7

Max.

Elevation

(m)

5

5

Additional

Refrigerant

(g/m)

-

-

Gas

3/8"

1/2"

Liquid

1/4"

1/4"

Indoor/Outdoor Unit Installation Diagram

About 1.1 m

Piping direction Attention not to

bend up drain hose

Length of power supply cord

Right

Right Bottom

Right Rear

Left

Rear

Left Bottom

Left

(Front side)

About 1.8 m

<

<

<

<

(Left and right are identical)

This illustration is for explanation purposes only.

The indoor unit will actually face a different way.

Installation plate

1

Sleeve ( )

Bushing Sleeve ( )

Putty (Gum type sealer) ( )

Vinyl tape (Wide) ( )

Apply after carr ying out a

drainage test.

To carry out the drainage

test, remove the air filters

and pour water into the heat

exchanger.

Saddle ( )

Additional drain hose ( )

Bend the pipe as closely on

the wall as possible, but be

careful that it doesn't break.

Installation parts you

should purchase ( )

1/4" Liquid side piping ( )

1

0

c

m

o

r

mo

r

e

Gas side piping ( )

3/8"

10

0c

m

or

m

o

re

30

cm

or

m

o

r

e

5cm

or more

Insulation of piping connections

Carry out insulation

after checking for

gas leaks and

secure with vinyl

tape.

Vinyl tape

5cm

or more

10 cm

or m

or

e

Type designation 245 IEC 57

or heavier cord

Connecting cable

2

(3-CORE WIRE/1.5mm ( )

CS-PC9DKV / CU-PC9DKV / CS-PC12DKV / CU- PC12DKV

CS/CU-PC9DKV :

1/2"

CS/CU-PC12DKV :

10

cm

or

mor

e

3

0cm

or

more

10

0

c

m

o

r

more

1

0c

m

o

r

m

o

r

e

CU-PC9DKV

CU-PC12DKV

Loading...

Loading...