Do you have a question about the Panasonic FP-X0 L14R and is the answer not in the manual?

Critical situations leading to death or serious injury from mishandling.

Critical situations leading to user injury or property damage from mishandling.

Copyright and trademark information for the manual and its content.

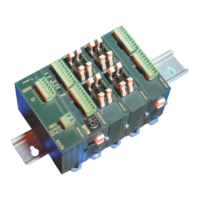

Classification and specifications of FP-X0 control units and expansion units.

Restrictions on connecting FP-X expansion units and FP0 adapters to control units.

Information on software environments and suitable cables for programming.

Identification and description of the parts and functions of control units.

Specifications for AC power supply and service power supply for input.

Detailed specifications for input and output types, including transistor and relay outputs.

Specifications and connection details for analog inputs on L40 and L60 types.

Diagrams showing the terminal layout for various FP-X0 control units.

Details on parts, functions, power supply, and I/O specifications for FP-X expansion units.

Description of the parts, functions, and general specifications of the FP-X FP0 adapter.

General I/O number allocation and how X and Y numbers are specified.

Fixed I/O number allocation for different FP-X0 control unit models.

I/O number allocation for FP-X expansion units based on their installation position.

I/O allocation for FP0/FP0R expansion units and the number of units that can be connected.

Details on installation environment, space requirements, and heat discharge measures.

Procedure for connecting FP-X expansion units using the expansion cable.

Instructions for wiring AC power supply and service power supply for input.

Guidelines for input and output wiring, including precautions for different sensor types.

Information on suitable terminals, wires, and tightening torque for terminal blocks.

Details on connecting and setting the COM port (RS485) for communication.

Instructions for using, replacing, and managing the backup battery.

Precautions for system design, power failures, and output section protection.

Description of communication modes like Computer Link, General-purpose Serial Communication, PC(PLC) Link, and MODBUS RTU.

Details on the Tool Port (RS232C) and COM Port (RS485) specifications.

Communication specifications for the Tool Port, including interface, baud rate, and format settings.

Explanation of the Computer Link function, including MEWTOCOL master and slave functions.

Details on sending and receiving data using general-purpose serial communication.

Explanation of the PC(PLC) link function, data sharing, and connectable PLCs.

Overview of MODBUS RTU communication, including master and slave functions.

Introduction to the three pulse I/O functions: high-speed counter, pulse output, and PWM output.

Specifications and restrictions for high-speed counter and pulse output functions.

Details on high-speed counter function, input modes, and control instructions.

Explanation of pulse output function, methods, operation modes, and instructions.

Description of the PWM output function and the instruction used for it.

Details on setting passwords to prohibit unauthorized reading and writing of programs.

Function to prohibit program upload by setting a disable upload option.

Functions available for the FP memory loader, including limited distribution and upload protection.

Summary table of security settings and cancellation options for the FP0R control unit.

Information on the clock/calendar function, its specifications, and how to set it.

Details on the sampling trace function for L40 and L60 types, including its overview and usage.

Explanation of time constant processing for input signals to remove noise.

Details on the P13 (PICWT) instruction for storing data in ROM.

How to read LED status indicators and understand operation modes when errors occur.

Troubleshooting steps for diagnosing issues based on LED status and error codes.

Outline of operation errors, types of errors, and how to handle them.

Explanation of duplicated output, how to check for it, and how to enable it.

Details on instructions that use the leading edge detection method and precautions.

Precautions related to programming when combining contacts and instructions.

Explanation of how to perform program rewriting during RUN mode and potential issues.

How forced input/output operations are processed during RUN mode.

General specifications including ambient conditions, breakdown voltage, and weight.

Environmental, electrical, and mechanical specifications of the control unit.

Performance specifications such as I/O points, program capacity, operation speed, and memory areas.

Communication specifications for Tool Port (RS232C) and COM Port (RS485).

Fixed I/O number allocation for different FP-X0 control unit models.

Details on relays, memory areas, and constants available for use.

Dimensional drawings and installation dimensions for control units and expansion units.

Specifications for PC connection cables and tool port extension cables/adapters.

Details on system registers, special internal relays, and special data registers.

A comprehensive table listing basic instructions, their symbols, and availability.

A table detailing high-level instructions, their types, operands, and availability.

Categorized list of error codes, their meanings, and troubleshooting steps.

Reference table for MEWTOCOL-COM communication commands.

Conversion tables for decimal, hexadecimal, binary, and BCD data.

Table of ASCII codes for character representation.

| Number of I/O points | 14 |

|---|---|

| Input points | 8 |

| Output points | 6 |

| Output Type | Relay |

| Power supply | 24V DC |

| Communication Port | RS232C |