-- 7 --

Fig. 6C Fig. 6D

FUEL AND LUBRICATION

OPERATING INSTRUCTIONS

WARNING: ALWAYS WEAR SHOU-

LDER HARNESS when operating unit with a

blade. Attach harness to trimmer after

starting unit and engine is running at IDLE.

Turn ENGINE OFF before disconnecting

shoulder harness.

SHOULDER HARNESS

NOTE: When you install the cutting

attachment, please follow the below

requirements.

1. Put the harness on so the shoulder strap

is over your LEFT shoulder.

2. Attach the harness clip (C) to the ring (D)

mounted on the shaft (Fig. 8A and 8B).

3. Adjust length of shoulder strap so trimmer

head is parallel to the ground as it hangs

from the strap. A few practice swings

without starting engine should be made to

determine correct balance.

NOTE: Detach the shoulder harness from

the unit before starting engine.

WARNING: Never use straight petrol

in your unit. This will cause permanent

engine damage and void the manufacturer’s

warranty for that product. Never use a fuel

mixture that has been stored for over 90

days.

WARNING: Lubricant must be a

premium grade oil for 2-stroke air cooled

engines mixed at a 40:1 ratio. Do not use

any 2-cycle oil product with a recommended

mixing ratio of 100:1. If insufficient lubrication

is the cause of engine damage, it voids the

manufacturer’s engine warranty.

WARNING: Lack of lubrication voids

engine warranty. Gasoline and oil must be

mixed at 40:1.

WARNING: Remove fuel cap slowly

when refueling.

WARNING: Alternative fuels (not

petrol) such as E-15 (15% alcohol), E-20 (20%

alcohol), E-85 (85% alcohol) are NOT

classified as petrol and are NOT approved for

use in 2-stroke petrol engines. Use of

alternative fuels will cause problems such as:

improper clutch engagements, overheating,

vapor lock, power loss, lubrication deficiency,

deterioration of fuel lines, gaskets and internal

carburetor components, etc. Alternative fuels

cause high moisture absorption into the

fuel/oil mixture leading to oil and fuel

separation.

This engine is certified to operate on unleaded

petrol. Before operation, petrol must be mixed

with a good quality 2-cycle air-cooled engine

oil designed to be mixed at a ratio of 40:1. A

40:1 ratio is obtained by mixing 5 liters of

unleaded petrol with 0,125 liter of oil. DO NOT

USE automotive oil or marine oil. These oils

will cause engine damage. When mixing fuel,

follow instructions printed on oil container.

Once oil is added to petrol, shake container

momentarily to assure that the fuel is

thoroughly mixed. Always read and follow the

safety rules relating to fuel before fueling your

unit.

FUEL REQUIREMENTS

Use good quality unleaded petrol. The lowest

recommended octane grade is 90 (RON).

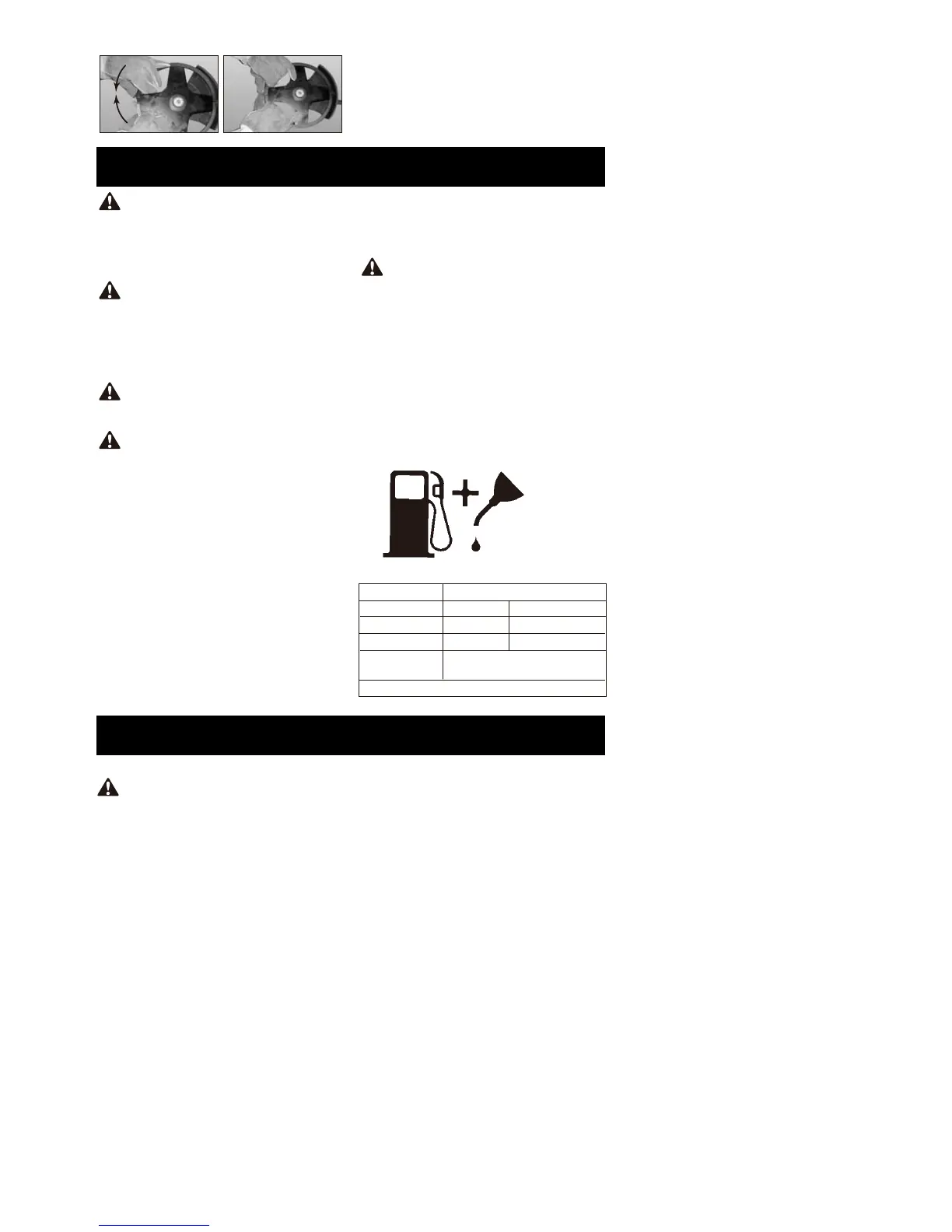

FUEL AND LUBRICATION

Gasoline and

Oil Mix 40:1

FUEL MIXING TABLE

GASOLINE 40:1 Ratio Lubricant

1 U.S. Gal. 3.2 oz. 95ml (cc)

5 Liters 4.3 oz. 125ml (cc)

1 lmp.Gal. 4.3 oz. 125ml (cc)

Mixing

Procedure

40 Parts Gasoline

to 1 part Lubricant

1ml = 1cc

IMPORTANT

Use of alcohol blended fuels (called gasohol

or using ethanol or methanol) can cause

major enging performance and durability

problems.

Loading...

Loading...