www.parweld.com www.parweld.com

5

cutting on a ceiling, oor, bulkhead, or partition can cause re on the

hidden side.

Do not cut on closed containers such as tanks, drums, or pipes,

unless they are properly prepared according to local regulations

Connect work cable to the work as close to the welding area as

practical to prevent cutting current from travelling along, possibly

unknown paths and causing electric shock, sparks, and re hazards.

Wear oil-free protective garments such as leather gloves, heavy

shirt, cufess trousers, high shoes, and a cap. Remove any

combustibles, such as a butane lighter or matches, from your person

before doing any cutting.

FLYING METAL can injure eyes.

Cutting, chipping, wire brushing, and grinding cause sparks and

ying metal. As cuts cool they can throw off slag. Wear approved

safety glasses with side shields even under your welding helmet.

BUILDUP OF GAS can injure or kill.

Shut off the gas supply when not in use. Always ventilate conned

spaces or use approved air-supplied respirator.

HOT PARTS can cause severe burns.

Do not touch hot parts with bare hands.

Allow cooling period before working on gun or torch.

To handle hot parts, use proper tools and/or wear heavy, insulated

welding gloves and clothing to prevent burns.

MAGNETIC FIELDS can affect pacemakers.

Pacemaker wearers keep away.

Wearers should consult their doctor before going near arc welding,

gouging, or spot welding operations.

NOISE can damage hearing.

Noise from some processes or equipment can damage hearing.

Wear approved ear protection if noise level is high.

Shielding gas cylinders contain gas under high pressure.

CYLINDERS can explode if damaged.

Protect compressed gas cylinders from excessive heat, mechanical

shocks, physical damage, slag, open ames, sparks, and arcs.

Install cylinders in an upright position by securing to a stationary

support or cylinder rack to prevent falling or tipping. Keep cylinders

away from any welding or other electrical circuits. Never drape a

cutting torch over a gas cylinder. Never allow a cutting tip to touch

any cylinder. Never cut a pressurized cylinder - explosion will result.

Use only correct shielding gas cylinders, regulators, hoses, and

ttings designed for the specic application; maintain them and

associated parts in good condition.

Turn face away from valve outlet when opening cylinder valve.

Use the right equipment, correct procedures, and sufcient number

of persons to lift and move cylinders.

Read and follow instructions on compressed gas cylinders,

associated equipment, and Compressed Gas Association (CGA)

recommendations.

2.0 Product Description

This welding machine is manufactured using

advanced inverter technology. The input voltage is rectied to

DC and then inverted to high frequency AC voltage. Before being

converted back to DC for the output .This allows the use of a much

smaller transformer and so allowing weight saving and improved

power efciency.

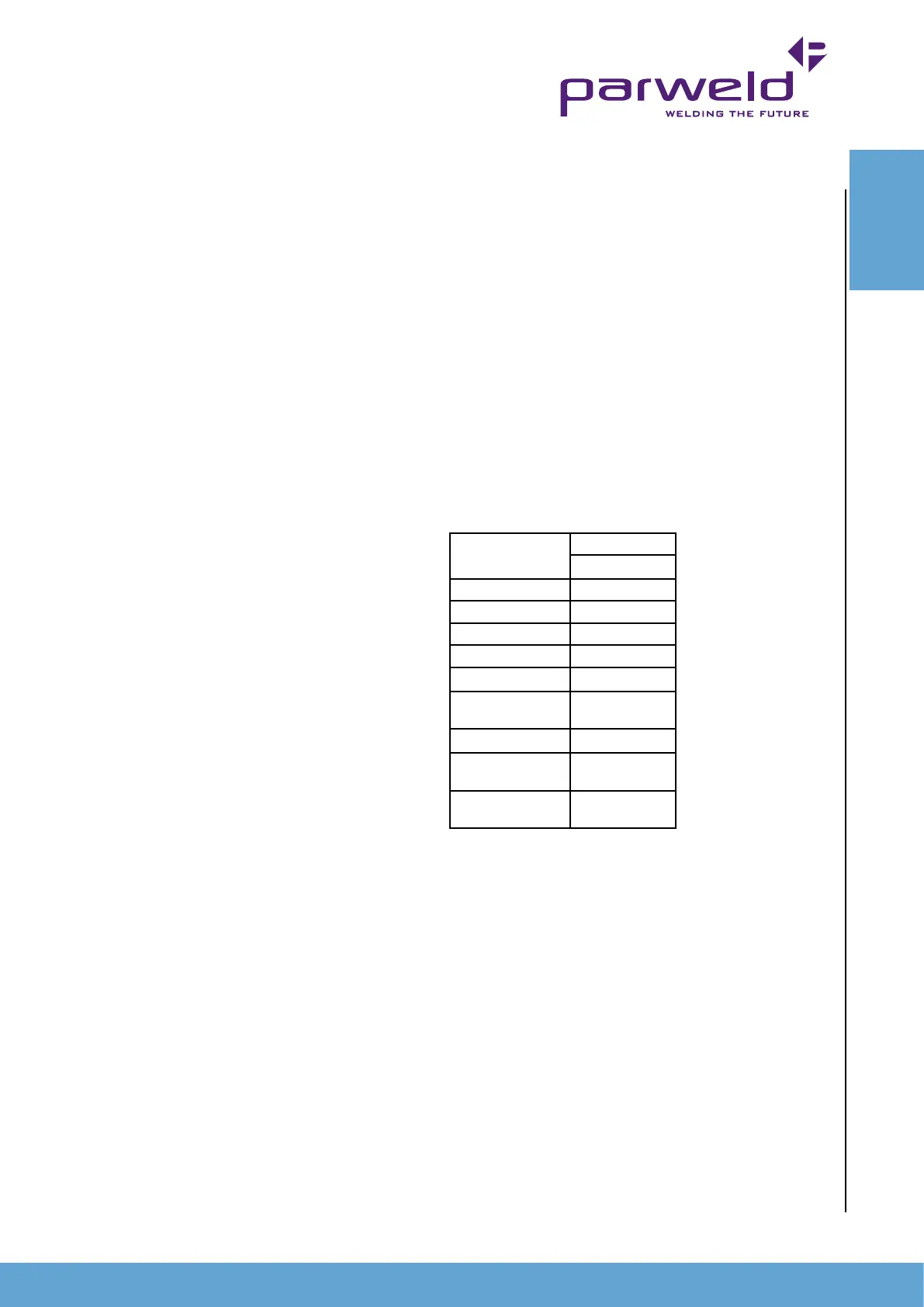

3.0 Technical

Specications

Data

Input voltage

400V +/- 10%

Frequency

50/60Hz

Input current

12A MAX

Fuse rating

16A (D rating)

Output OCV

480V

Output load

voltage

88-96V

Output Current

20-60A DC

Cutting capacity

Production

20mm

Cutting Capacity

Severance

30mm

SAFETY

Loading...

Loading...