5

A. SETTING THE BOILER

1. Provide a level foundation, located as close as

possible to the center of the heating system.

2. Refer to Figure 2.3 for exploded view of boiler while

checking and/or assembling parts of the boiler.

3. See clearance information in Section 1,

“Preinstallation.”

4. On packaged boilers, open burner mounting plate

(Item 4) at this time to make certain the target wall

(Item 2) is seated in the back of the combustion

chamber. Ceramic fiber blanket base liner (Item 3)

should be lying flat on bottom of combustion

chamber between target wall and burner.

B. FLUE BAFFLES - EC(T)-e MODELS ONLY

1. Flue baffles are for use on EC(T)-e models only.

Do not install flue baffles on EC-05-250 or EC-06

models. Applicability of flue baffles is also shown in

burner specification tables in Section 5.

2. Packaged Boilers - Flue baffles are factory installed

in 03 thru 05 section boilers. Remove flue baffles if

converting to EC-05-250 rate.

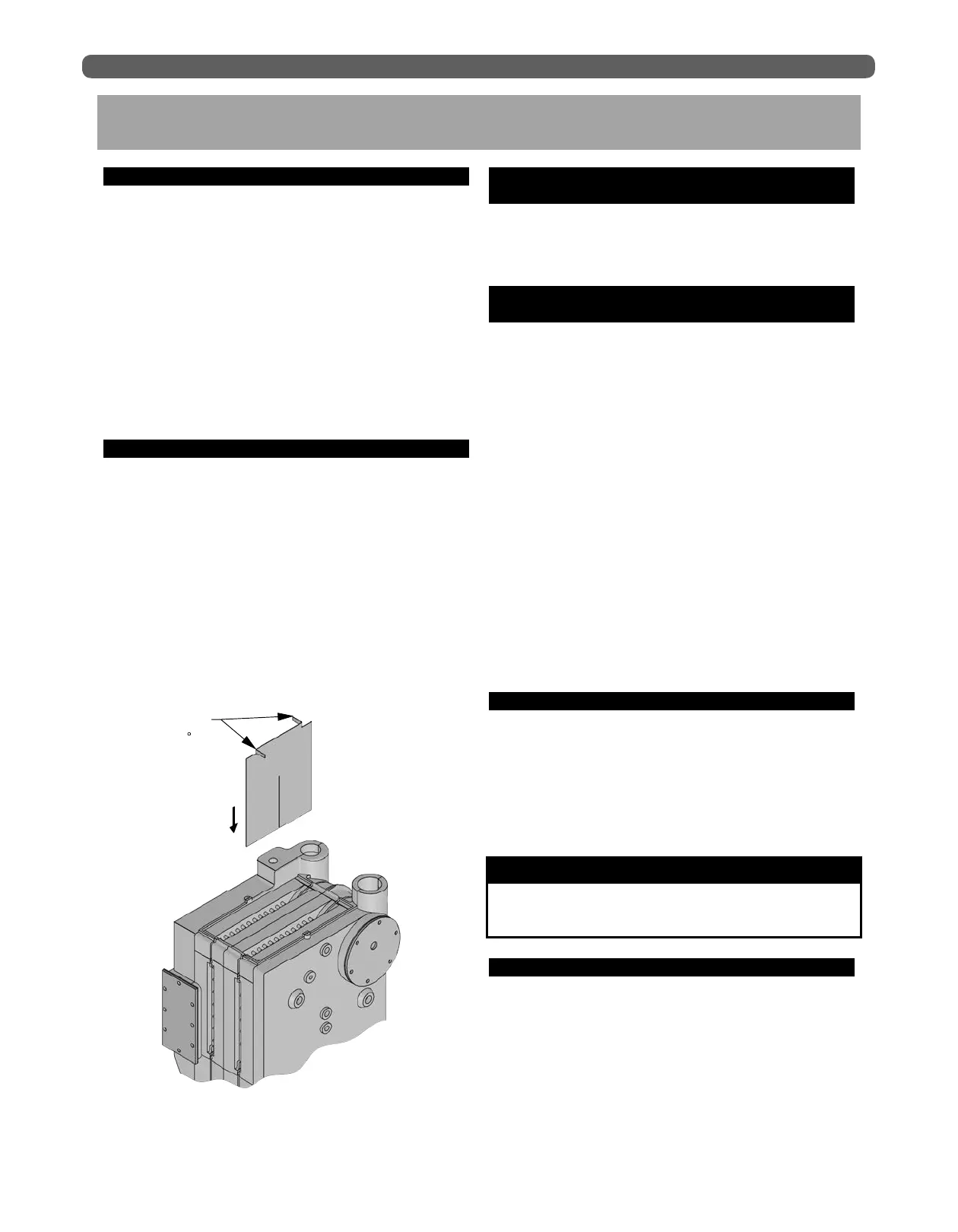

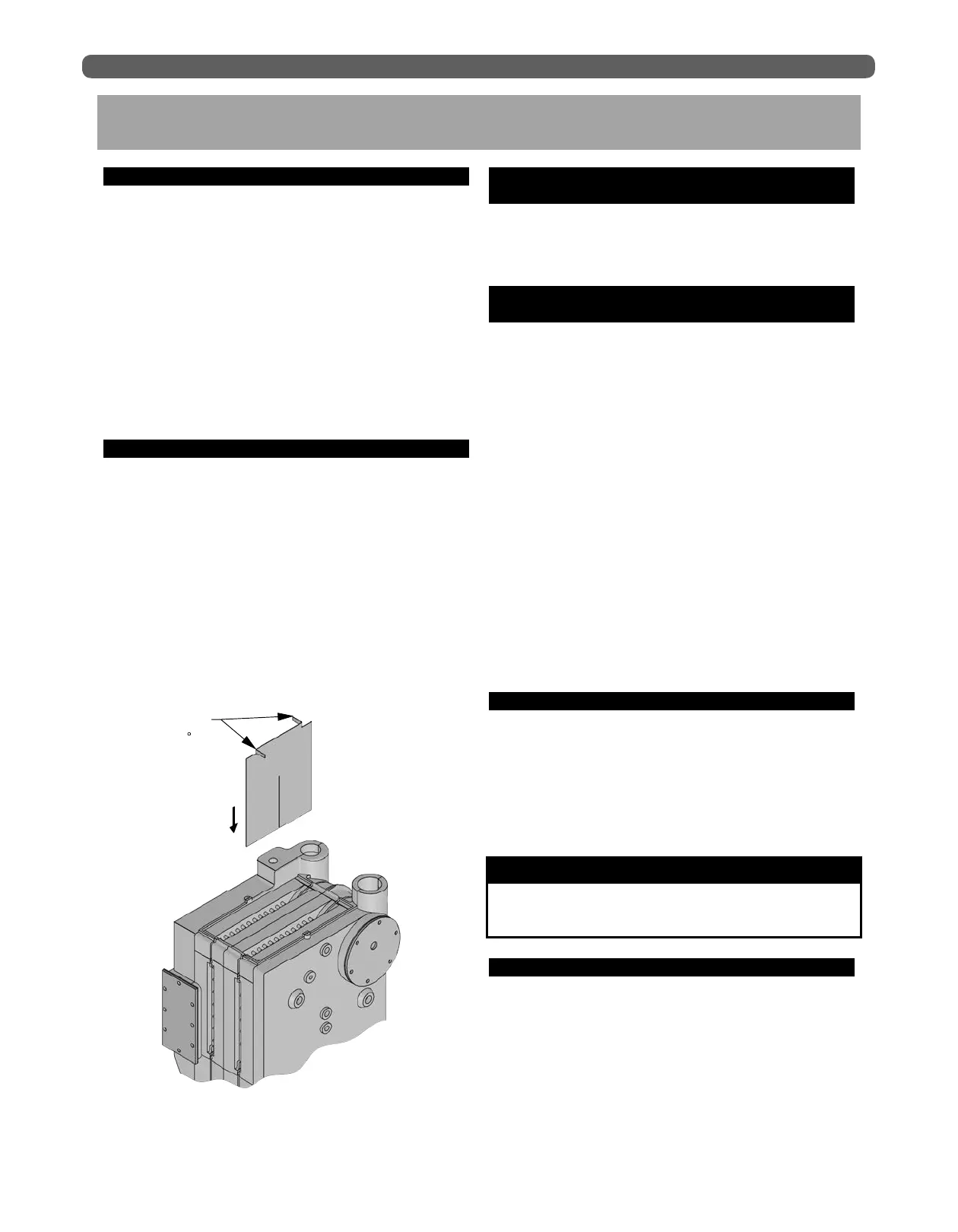

3. Knock-Down Boilers - Flue baffles are located in

03 thru 05 section jacket cartons. Bend baffle tabs as

shown in Figure 2.1 and suspend baffles from top of

flueways. Install one baffle per flueway. Do not install

baffles if converting to EC-05-250 rate.

C. OBSERVATION COVER ASSEMBLY

(KNOCKDOWN BOILERS)

1. Remove observation door (Item 6) from inside

burner mounting plate. Attach the observation door

to the outside of the mounting plate.

D. INSTALLATION OF FLUE COLLECTOR &

COVERPLATES (KNOCKDOWN BOILERS)

1. Open flue collector carton. Remove flue collector

(Item 13) and high temperature rope. Lay rope

(Item 14) on top of boiler against bead provided.

Place flue collector on top of rope and attach to

boiler with 1/4”-20 x 1-3/4” studs with nuts through

flue collector brackets into the tapped lugs provided

in the top of the boiler end sections. Draw nuts down

snugly.

2. Remove clean-out cover plates and insulation

(Items 24 and 25). Each clean-out cover plate is

attached to the boiler by using two carriage bolts,

nuts and washers (Item 26). Install the carriage bolts

into the notch at the top and bottom of each clean-

out opening, then secure them with a flat washer

and steel nut as shown in Figure 2.2 locking them

in place. Press the clean-out plate with insulation

over the protruding carriage bolts until the bolts

punch through the insulation so flat washer and

brass nut can be installed. Tighten down nuts snugly

compressing the insulation to form a good seal

around the clean-out opening.

E. TANKLESS HEATER OR COVERPLATE

If an ECT steam boiler is to be installed with a tankless

heater coil, the coil must be installed before the left side

jacket panels are attached. When a tankless heater is

not employed, cover the heater opening with cover plate

(Item 17 or 21).

See Section 3, Piping and Controls, for piping

information.

F. JACKET ASSEMBLY

1. Refer to Figure 2.3 for exploded view.

2. Attach the back panel to bosses on middle of back

section with two 1/4” x 3/8” truss head machine

screws (Item 27) provided. The back panel has two

5/16” diameter holes close to the center of the panel.

3. Lift off the burner mounting plate.

2. BOILER PLACEMENT & ASSEMBLY

BOILER PLACEMENT & ASSEMBLY

Be sure rubber gasket is in place between cover

plate or water heater plate and boiler section.

NOTICE

INSTALL FLUE

BAFFLES ON

EC(T)-e MODELS,

1 PER

FLUEWAY.

BEND TABS

90

IN

OPPOSITE

DIRECTIONS

Figure 2.1: Flue Baffle Installation, EC(T)-e Models

Loading...

Loading...