ENGLISH

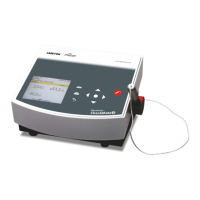

“SAS SUPER IAQ” - Code n. 90578

I

I

N

N

S

S

T

T

R

R

U

U

C

C

T

T

I

I

O

O

N

N

S

S

M

M

A

A

N

N

U

U

A

A

L

L

Carefully read this Manual before operating your instrument.

This document is the property of International PBI Spa Milan

It may not be duplicated or distributed without the owner’s authorisation

Patent Pending

Manufactured by International PBI Spa Milan, Italy

REFERENCES

FDA – 1987 Guideline on Sterile Drug Products produced by Aseptic Process

ACGIH – Guideline for the Assessment of Bioaerosol in the Indoor Environment

ASTM – Draft Protocol – Committee D22.05.06

USP 23-NF 18 8

th

Supplement 1116 (May 1998) – Microbiological Evaluation of Clean Rooms

and other Controlled Environments

EU Guide for GMP – Manufacture of Sterile Medicinal Products Control of Medicines and

Inspection

CEN/TC 243 Norms for Clean Room Technology

International PBI S.p.A.

Via Novara, 89 – 20153 Milano – Italy – Tel + 39 02 48779-1– Fax + 39 02 40090010

E-mail:

info@internationalpbi.it – www.internationalpbi.it