5.0 VOLTAGE RECOMMENDATIONS

AS 3894.1 recommends minimum voltages for testing specified

thickness of film of various Coating Products

Tables 1 and 2 below provide guidance for determination of minimum

voltage for high voltage porosity testing of the indicated generic types of

coating products, at the indicated dry film thicknesses which may

contain residual solvents.

V = minimum test voltage applied in volts

T = dry film thickness of cured coating in microns

F = a whole number factor which rates a coating’s generic

type and residual solvent content (Table 1)

The above minimum test voltages have been derived from Australian

Standard AS3894.1; the whole of this Standard should be used. The

above voltages relate to the following: the detector should have a direct

earth connection to the substrate and a fine wire brush electrode must be

connected to the probe.

ALLOW AN ADDITIONAL 200 VOLTS IF THE NEON IN THE PROBE HANDLE IS IN USE.

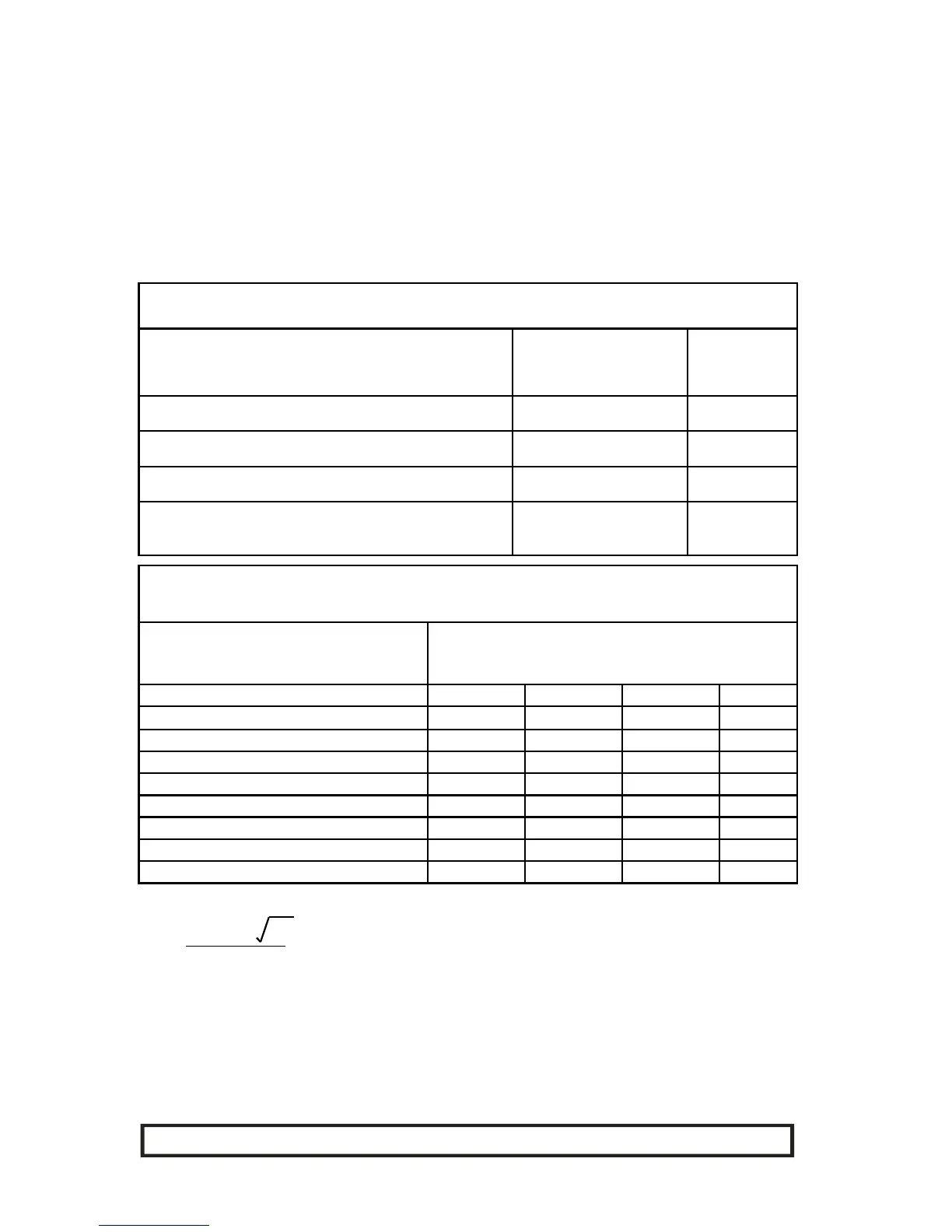

Table 1. Determination of the coating film rating (F) from coating type and

volume solids content.

Generic Type of Coating

Volume Solids %(V/V)

Volume Solids

%(V/V)

Factor (F)

Factor

(F)

Chorinated Rubber, Vinyl

15 to 39 4

Low Build Epoxy, some Tar Epoxy

40 to 59 3

High Build Epoxy, some Tar Epoxy

60 to 79 2

Polyester/Vinyl esters, Solventless Epoxy,

Fusion-bonded Epoxy.

80 and greater 1

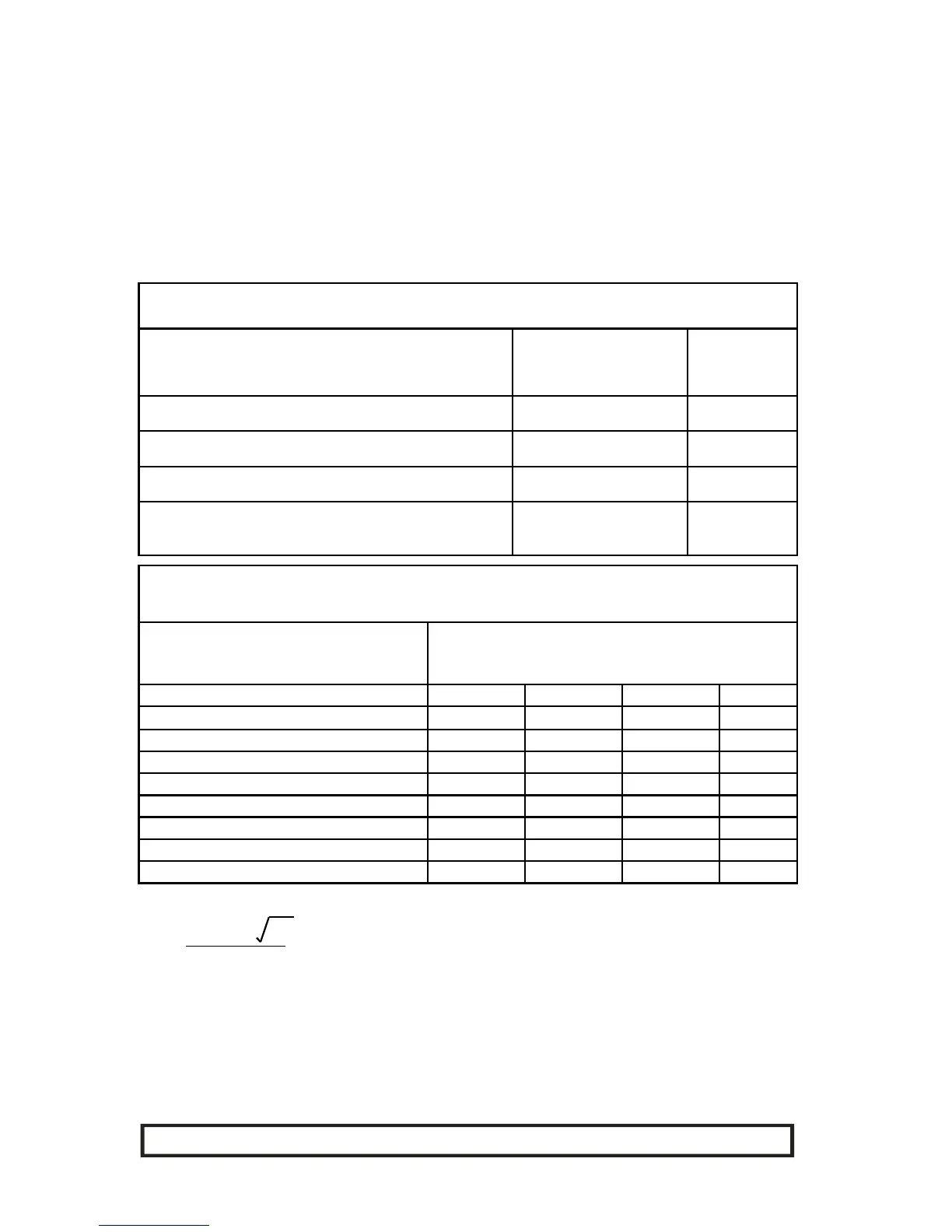

Table 2. Determination of the test voltage (V) from dry film

thickness (T) and coating material rating (F).

Nominal dry film thickness in

microns

Test Voltage (kV)

F=1 F=2 F=3 F=4

150 3.06 1.53 1.01 0.77

250 3.96 1.98 1.32 0.99

400 5.00 2.50 1.67 1.25

600 6.12 3.06 2.04 1.53

800 7.07 3.54 2.36 *

1500 9.69 4.84 * *

2500 12.50 * * *

4000 15.81 * * *

V = 250 x T

F

8

Loading...

Loading...