2. The hydraulic oil of the lifts should be replaced regularly during using. Replace the

hydraulic oil 3 months after the first installation, Replace the hydraulic oil once a

year afterwards.

3. Make at least one full trip raising and lowering per day. For exhausting the air from

the system, which could effectively avoid the corrosion of the cylinder and damage

to the seals caused by presence of air or water in the system.

4. Protect the outer surface of the oil cylinder’s piston rod from bumping and

scratching, and timely clean up the debris on the oil cylinder dust-ring and the

piston rod.

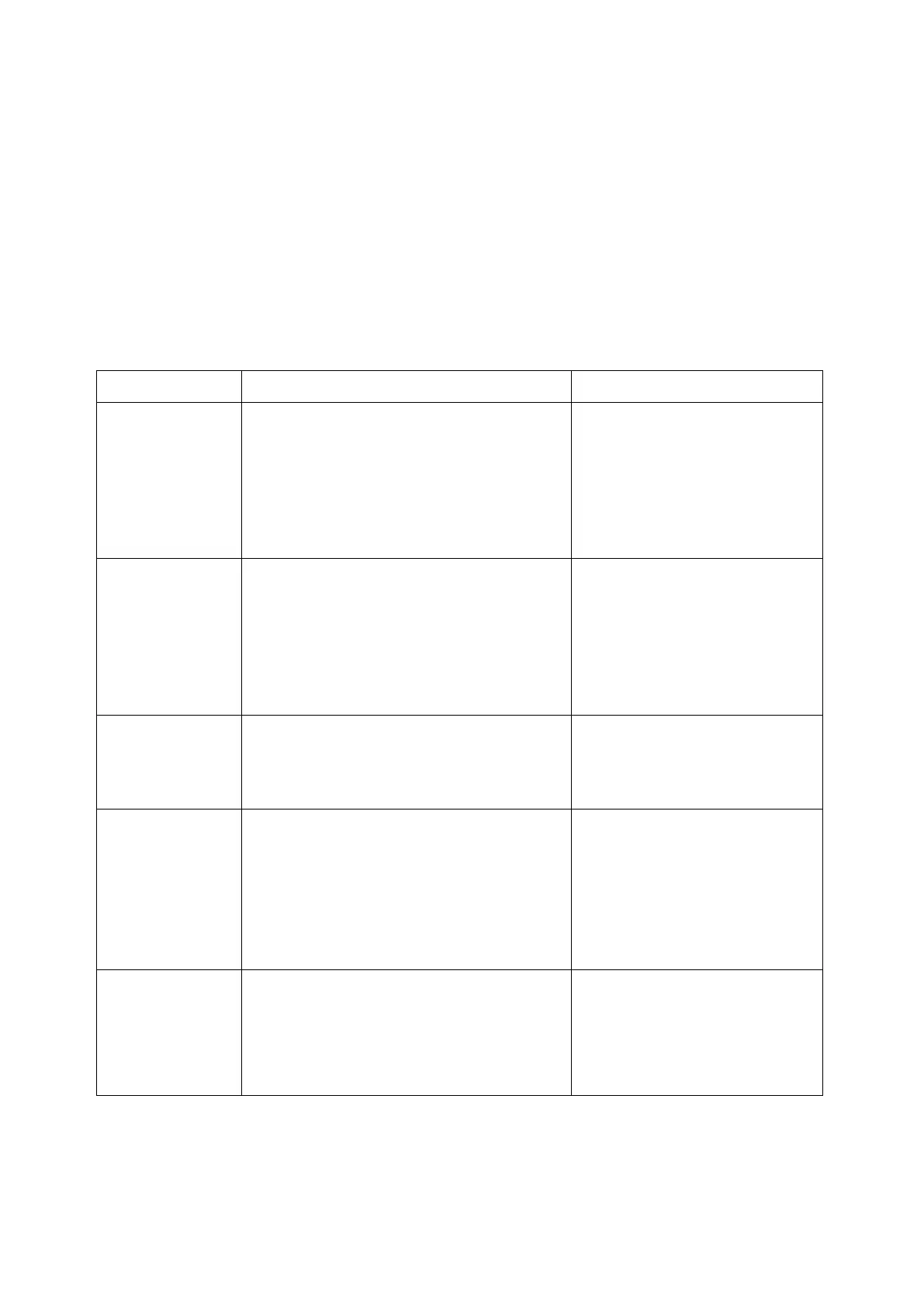

VIII.TROUBLE SHOOTING

1. Button does not work

2. Wiring connections are not in good

condition

3. Motor burned out

4. AC contactor in damage

1. Replace button

2.Repair all wiring connections

3. Repair or replace motor

4. Repair or replace

Motor runs but

the lift is not

raised

1. Motor runs in reverse rotation

2. Gear pump out of operation

3. Release valve in damage

4. Relief valve or check valve in damage

5. Low oil level

1.Reverse two power wire

2.Repair or replace

3. Repair or replace

4.Repair or replace

5.Fill tank

1. Release valve out of work

2. Relief valve or check valve leakage

3. Cylinder or fittings leaks

1. Hydraulic System is jammed

2. Motor running on low voltage

3. Oil mixed with air

4. Gear Pump leaks

5. Overload lifting

1. Clean the Hydraulic System

2. Check electrical system

3. Fill tank

4. Repair or replace

5. Check load

1. Safety device are locking.

2. Release valve in damage

3. Safety cable broken

4. Oil system is jammed

1. Release the safeties

2. Repair or replace

3. Replace

4. Clean the oil system

IX. lift disposal: When the car lift cannot meet the requirements for normal use

and needs to be disposed, it should follow local laws and regulations.

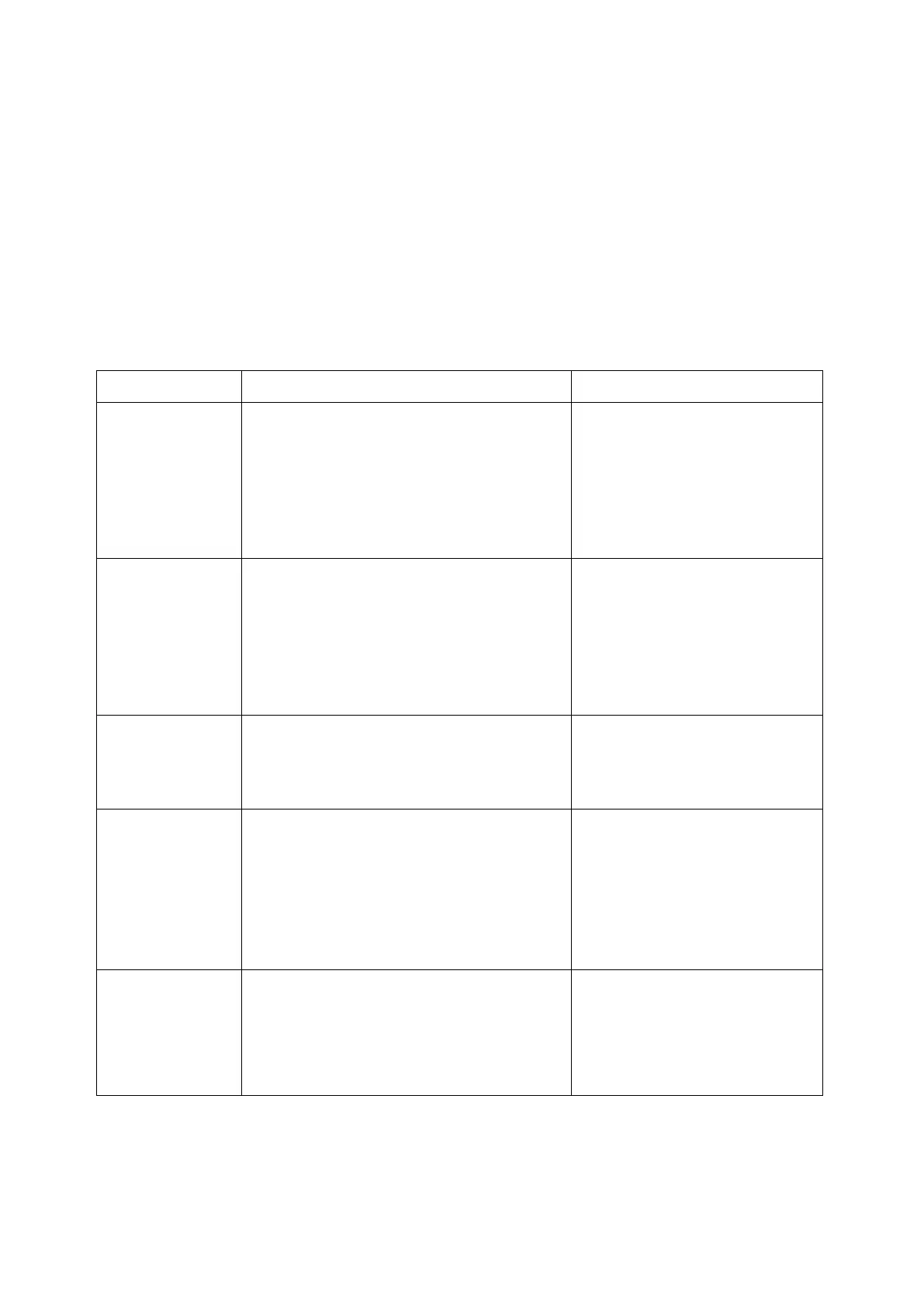

X. PARTS LIST FOR MODEL 212

Loading...

Loading...