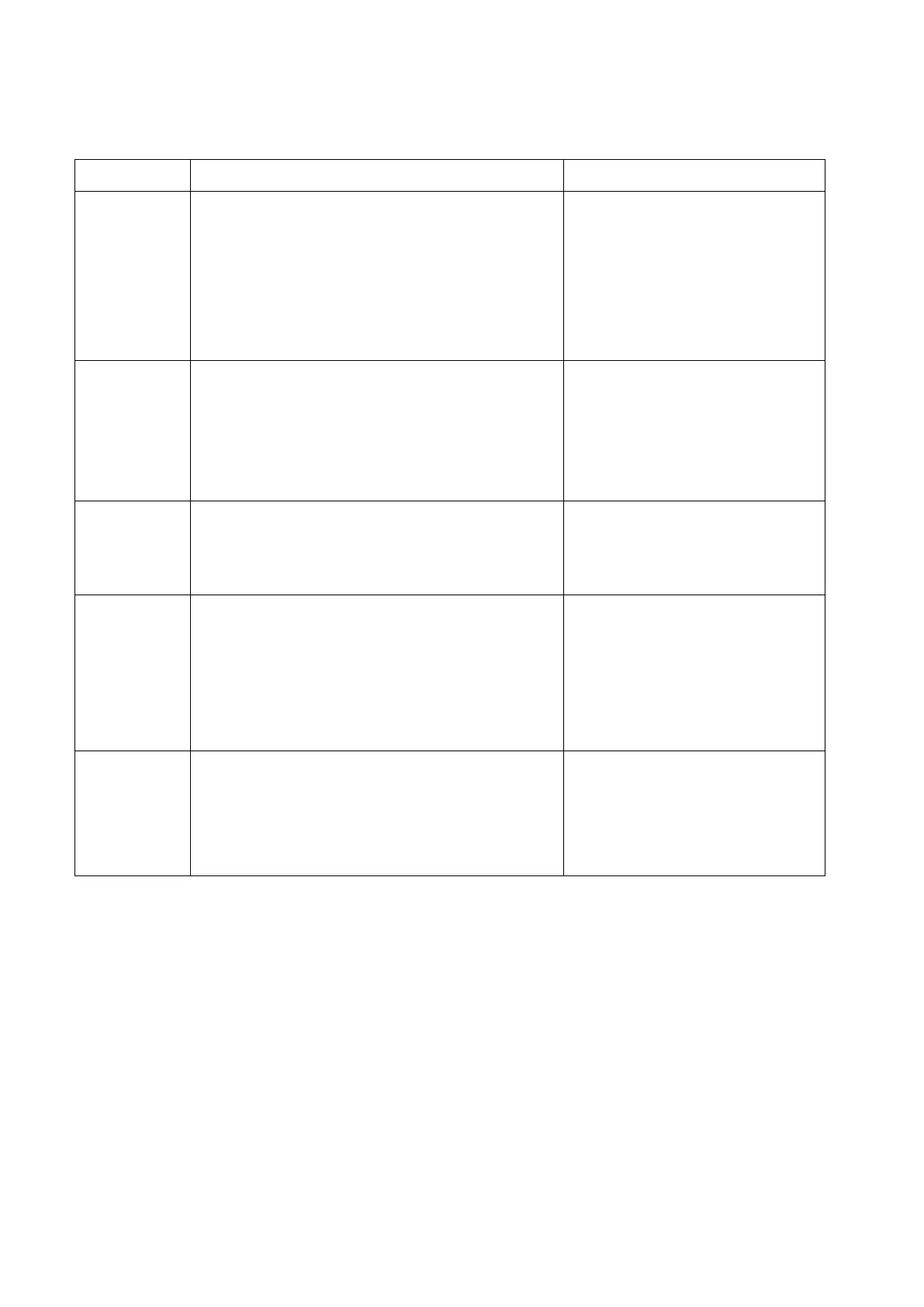

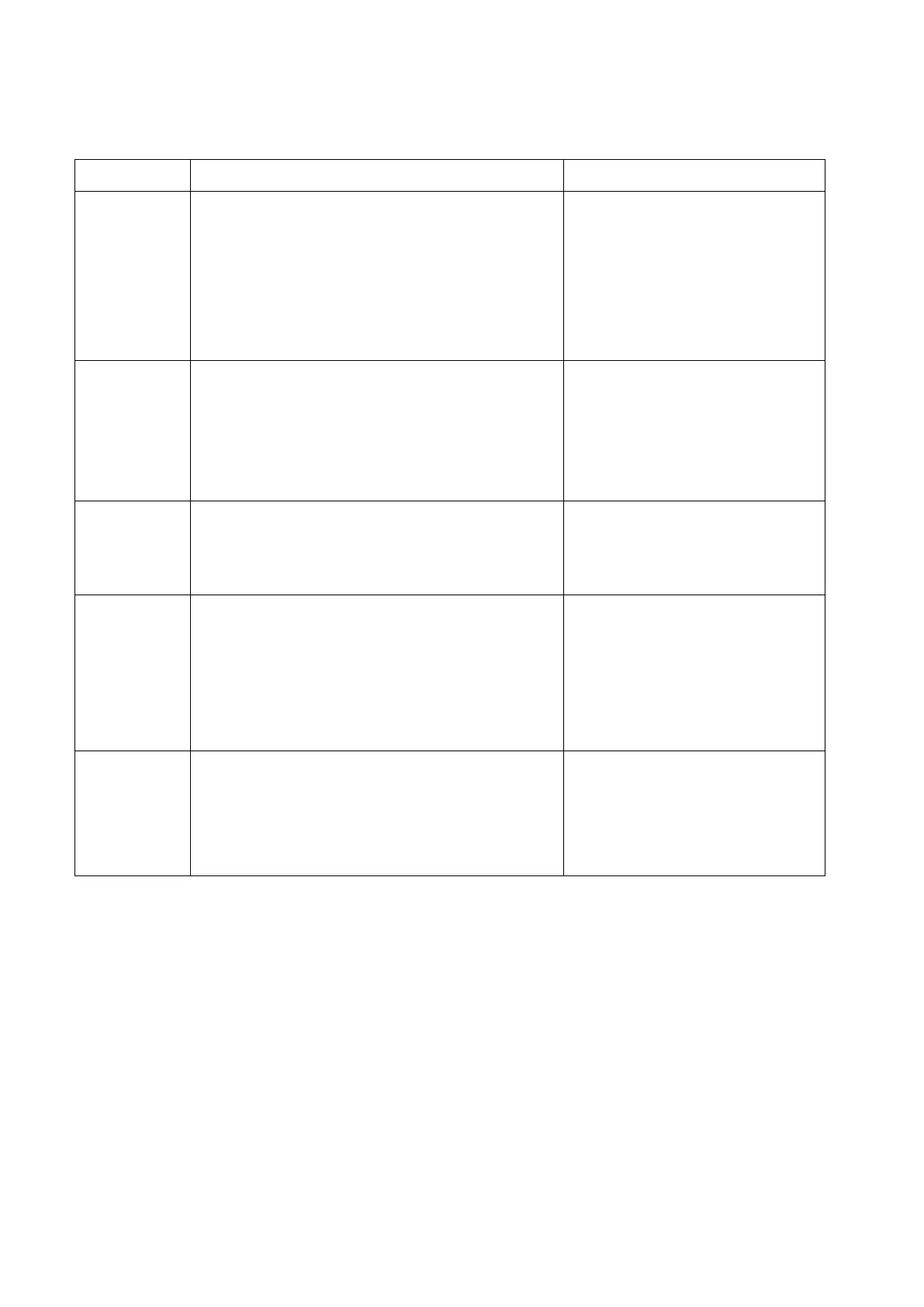

VIII. TROUBLE SHOOTING

IX. SCARPING OF EQUIPMENT

Once the equipment is unusable and needs to be scarped, please follow the local laws

and regulations.

1. Button does not work

2.Wiring connections are not in good condition

3. Motor burned out

4. AC contactor burned out

5. Height limit switch is damaged

1.Replace button

2.Repair all wiring connections

3.Repair or replace motor

4.Replace AC contactor

5.Replace

Motor runs

but the lift is

not raised

1.Motor runs in reverse rotation

2. Hydraulic solenoid valve in damage

3.Gear pump in damage

4.Relief valve or check valve in damage

5.Low oil level

1.Reverse two power wire

2.Repair or replace

3.Repair or replace

4.Repair or replace

5.Fill tank

1.Solenoid valve out of work

2 Relief valve or check valve leakage.

3.Cylinder or fittings leaks

1.Oil line is jammed

2.Motor running on low voltage

3. Oil mixed with Air

4.Pump leaks

5.Overload lifting

1.Clean the oil line

2.Check electrical system

3. Fill tank

4.Replace Pump

5.Check load

1.Air solenoid valve damaged

2. Hydraulic solenoid valve damaged

3.Air Cylinder damaged

4. Air –line leaked

1.Replace or repair

2.Replace or repair

3.Replace the cylinder

4.Check the air-line

Loading...

Loading...