1020 Mono Filler

21

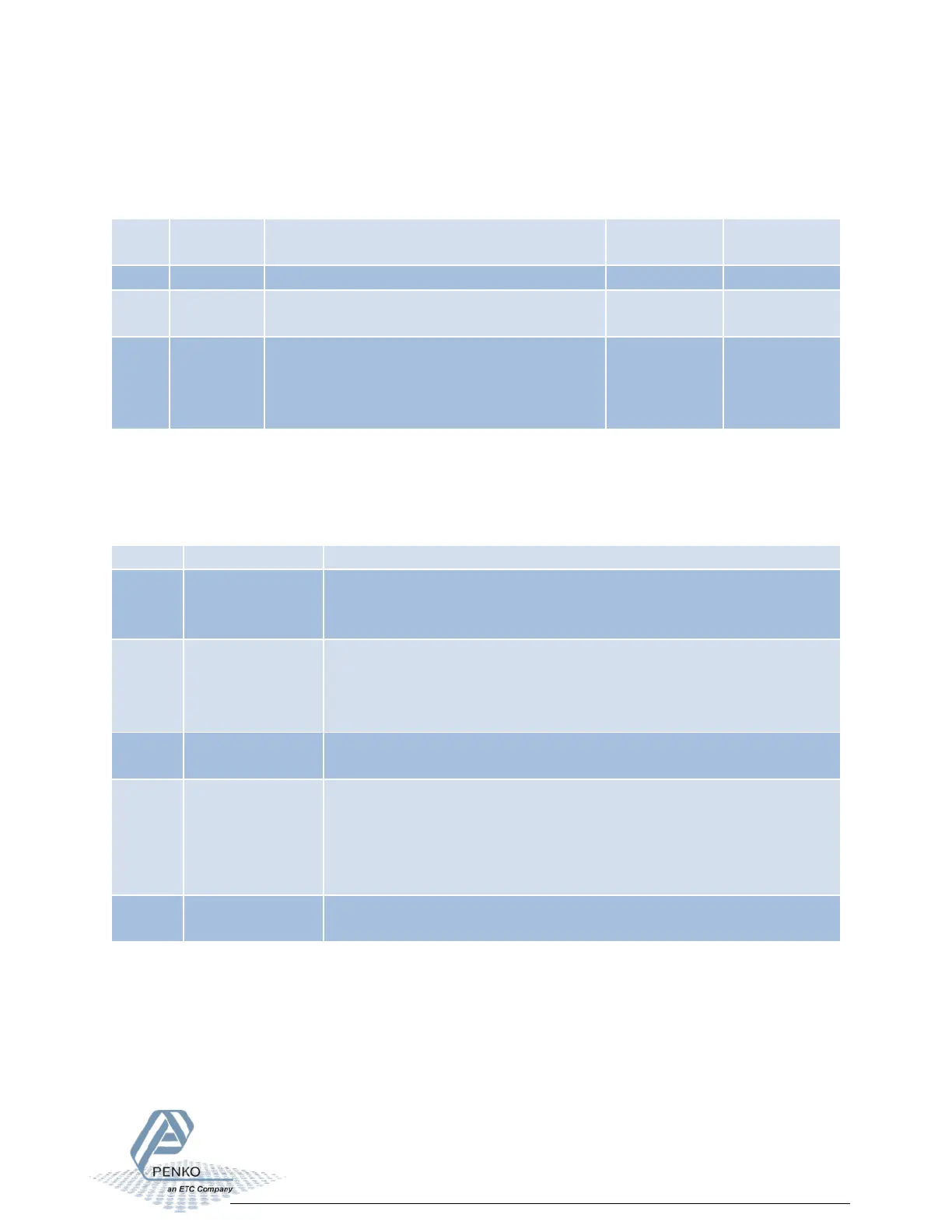

5 Inputs and outputs

The following inputs and outputs are used.

5.1 Inputs

Input must be high to run the program

Input to accept the dosing when the end

value is out of tolerance.

dosing or

start

Input to start dosing or release (depends

on the configuration parameters) when

the ready output is ON.

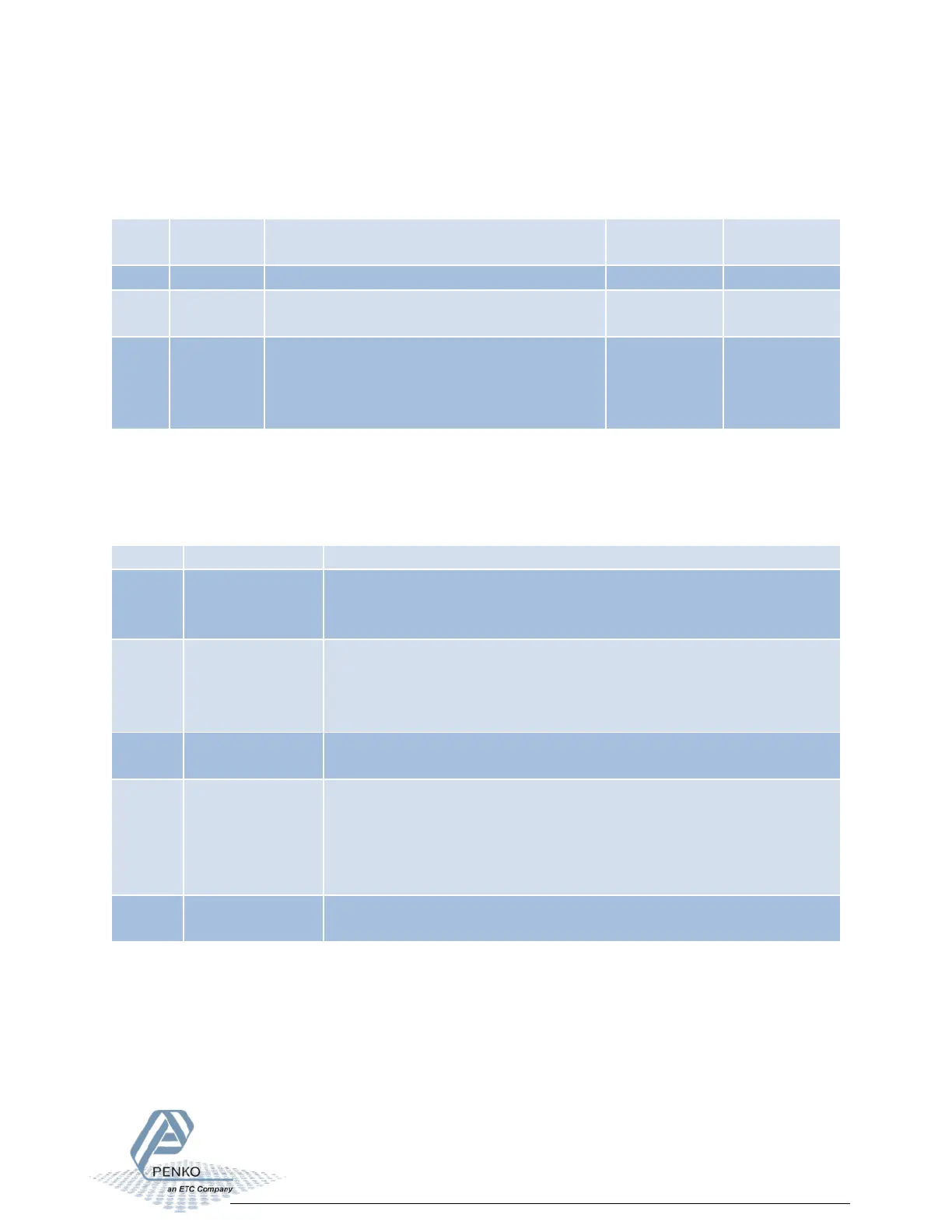

5.2 Outputs

Output to enable coarse dosing.

The output turns on when the dosing starts and will turn off

when the setpoint minus the turnover value is reached.

Output to enable fine dosing.

The output turns on when the dosing starts and will turn off

when the setpoint minus the inflight value is reached.

The output also turns on if the end value is under the tolerance.

Output to enable the ready output. The output turns on when

dosing is not busy.

Alarm

When a release valve is selected in the configuration, this output

is used to activate the release valve.

When no release valve is selected in the configuration, this

output is used to activate the indicator alarm. This alarm can be

reset by switching off input 1.

Dosing speed for coarse/fine filling will be available from 0,00%

to 100,00%

Loading...

Loading...