1020 Mono Filler

18

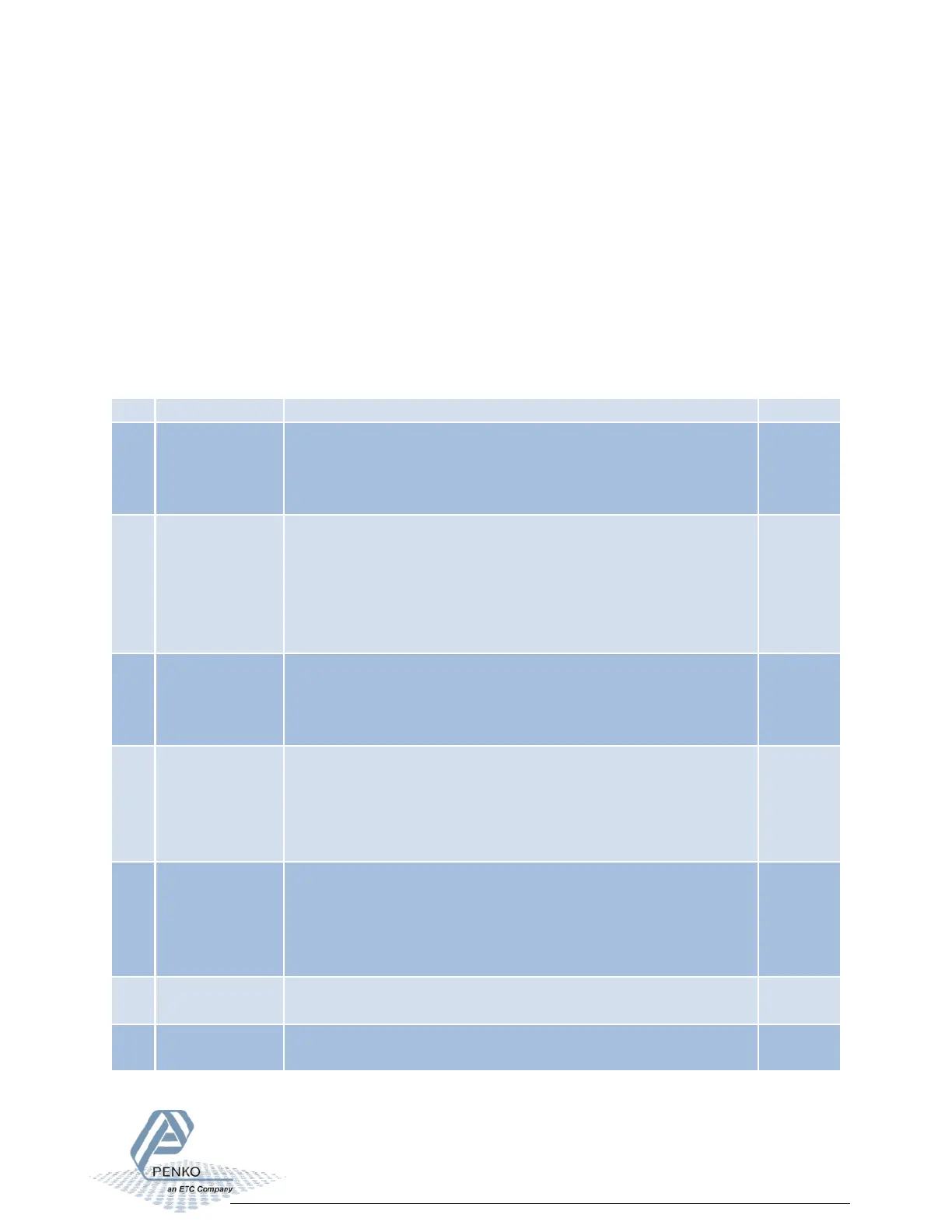

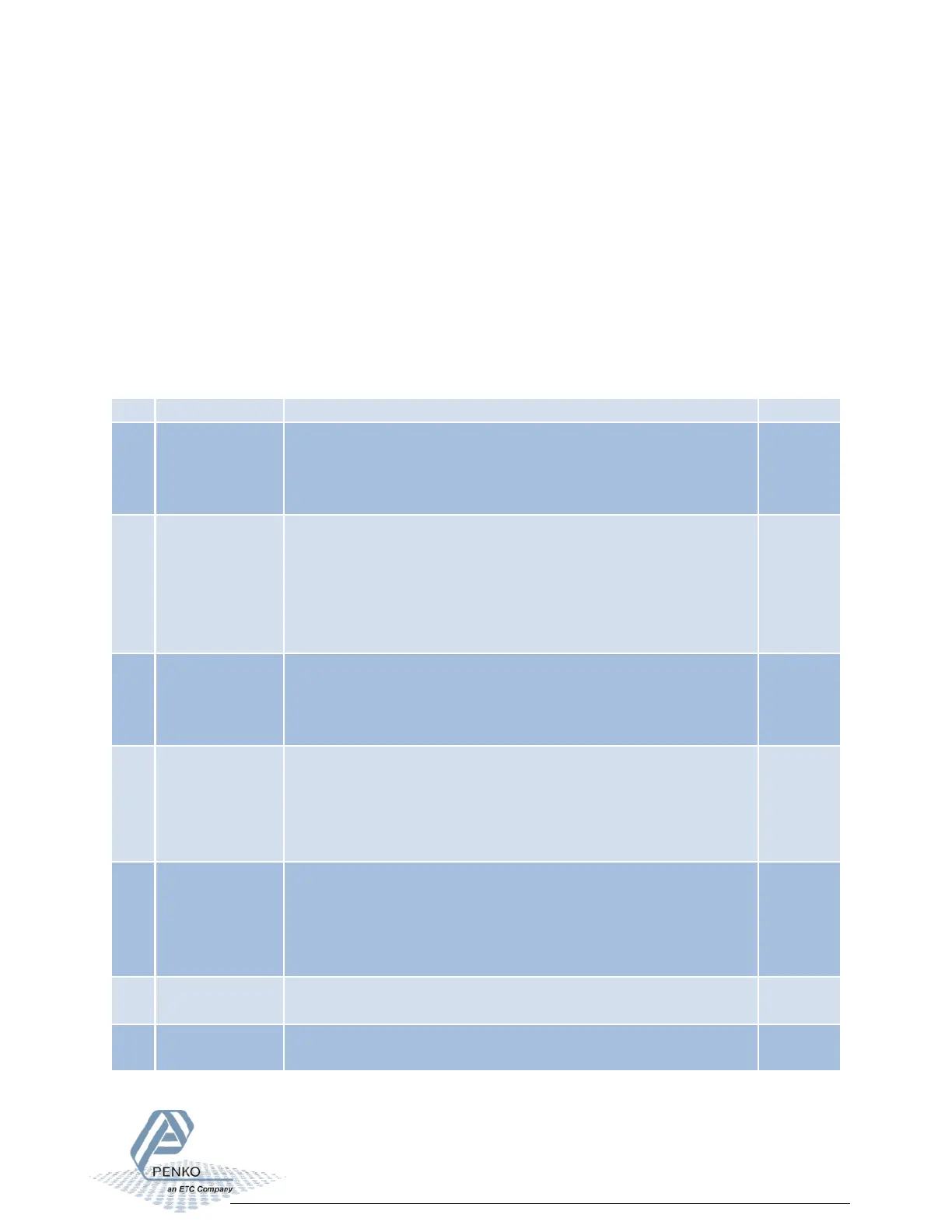

4.2 Recipe parameters

These parameters correspond with the parameters in the tree structure of the device Recipe.

When using the industrial protocol register functions, each parameter can be reached using its

number.

Some parameters can be reached directly using ASCII, TP protocol, Modbus RTU, Modbus TCP,

Fins, Profibus or EtherNet/IP. The parameters for Profibus or EtherNet/IP are prefixed with PB

or EIP.

Note: when the device is rebooted or the recipe is manually changed, all recipe parameters are

changed back to the value that were last set manually in the recipe.

The amount of product that is wanted on/into or out of the

weigher.

The selection net or gross and in or out is made in the

EIP-R11

Coarse dosing stops when the setpoint minus the turnover

is reached. The dosing continues in fine mode. The

correction strength is set in the configuration menu.

Δ The remaining fine time must be more than the K.E.B.

EIP-R12

The amount of product that falls on/into the weigher after

the fine output is switched off. This value can be

automatically corrected using the inflight correction in the

EIP-R13

tolerance

The allowed tolerance of the end value under the setpoint.

The fine output will stay on until the weight is within this

range.

Δ Not used if no tolerance is selected

tolerance

The allowed tolerance of the end value above the setpoint.

An alarm will be generated until the weight is accepted by

input 2.

Δ Not used if no tolerance is selected

During coarse dosing mode this value is used for the analog

output.

During fine dosing mode this value is used for the analog

output.

Loading...

Loading...