P266 Series Single-Phase Condenser Fan Speed Controls Installation Instructions 7

The start voltage value is a percentage of the

P266 Series Control input voltage. Use the following

formula to calculate the start voltage value for your

application.

Low Pressure Mode

Low pressure mode determines whether the fan motor

is either on (at start voltage/minimum speed) or off

when the sensed pressure at the P266 Transducer is

below the start pressure setpoint.

Start Pressure Value

Start pressure (psig or bar) is the pressure setpoint at

which the P266 Series Control outputs the start voltage

and runs the fan motor at minimum speed. Start

pressure value is a function of the start pressure

setpoint and the pressure range of the referenced

P266 Transducer. Use the following formula to

calculate the start pressure value. See Table 3 for

P266 Transducer pressure ranges.

End Pressure Setpoint Value

The end pressure setpoint is the pressure (bar or psig)

at which the P266 Series Control outputs the end

voltage and runs the fan motor at maximum speed.

End pressure value is a function of the end pressure

setpoint and the total pressure range of the referenced

transducer. Use the following formula to determine your

application end pressure value. See Table 3 for

P266 Transducer pressure ranges.

Split Winding Mode

Some single-phase PSC motors have split motor

winding wire leads. Setting the split winding mode on

enables the M2 triac to provide voltage to the main

windings (and not the auxiliary windings), which

increases motor efficiency.

Note: Split winding mode is available for only

240 VAC single-phase PSC motors that have split

winding wire leads. Refer to the motor manufacturer

installation instructions to determine if your fan motor

may be wired to enable the split winding mode.

Copeland Digital Scroll™ Compressor Mode

Digital scroll compressor mode allows you to use the

P266 Series Control on a system that uses a digital

scroll compressor. Failure to enable the digital scroll

compressor mode when using a digital scroll

compressor may cause your condenser fan to oscillate.

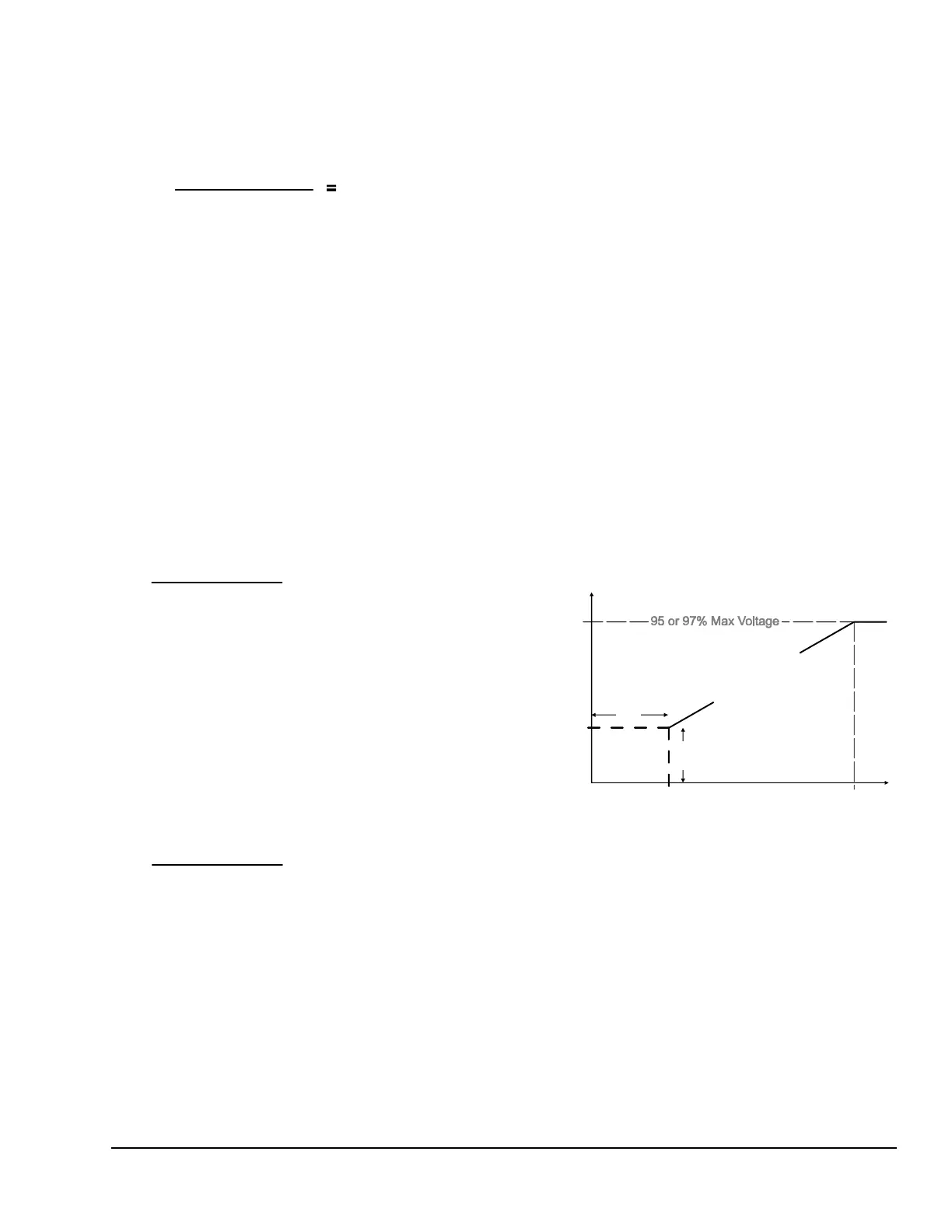

End Voltage Mode

End voltage mode is the voltage output by the

P266 Series Control (as a percentage of the full

voltage) that is maintained when the monitored

pressure is equal to or greater than the end pressure.

The end voltage mode can be set to either 95% or 97%

of the total input voltage. See Figure 5.

Start Voltage (VAC)

Input Line- Voltage (VAC)

Start Pressure

Setpoint (bar or psi)

P266 Transducer Pressure

Range (bar or psi)

X

250

End Pressure

Setpoint (bar or psi)

P266 Transducer Pressure

Range (bar or psi)

X

250

Figure 5: Relationship between

P266 Series Control Variables

Start

Pressure

0

Start

Voltage

End

Voltage

Mode

Low Pressure Mode

Voltage to Motor

Pressure at Sensor

l

t

a

g

e

t

o

M

o

t

o

r

FIG:

26 6_Valu_Rels

Loading...

Loading...