P66 Series Electronic Fan Speed Controls Installation Instructions 5

Setup and Adjustments

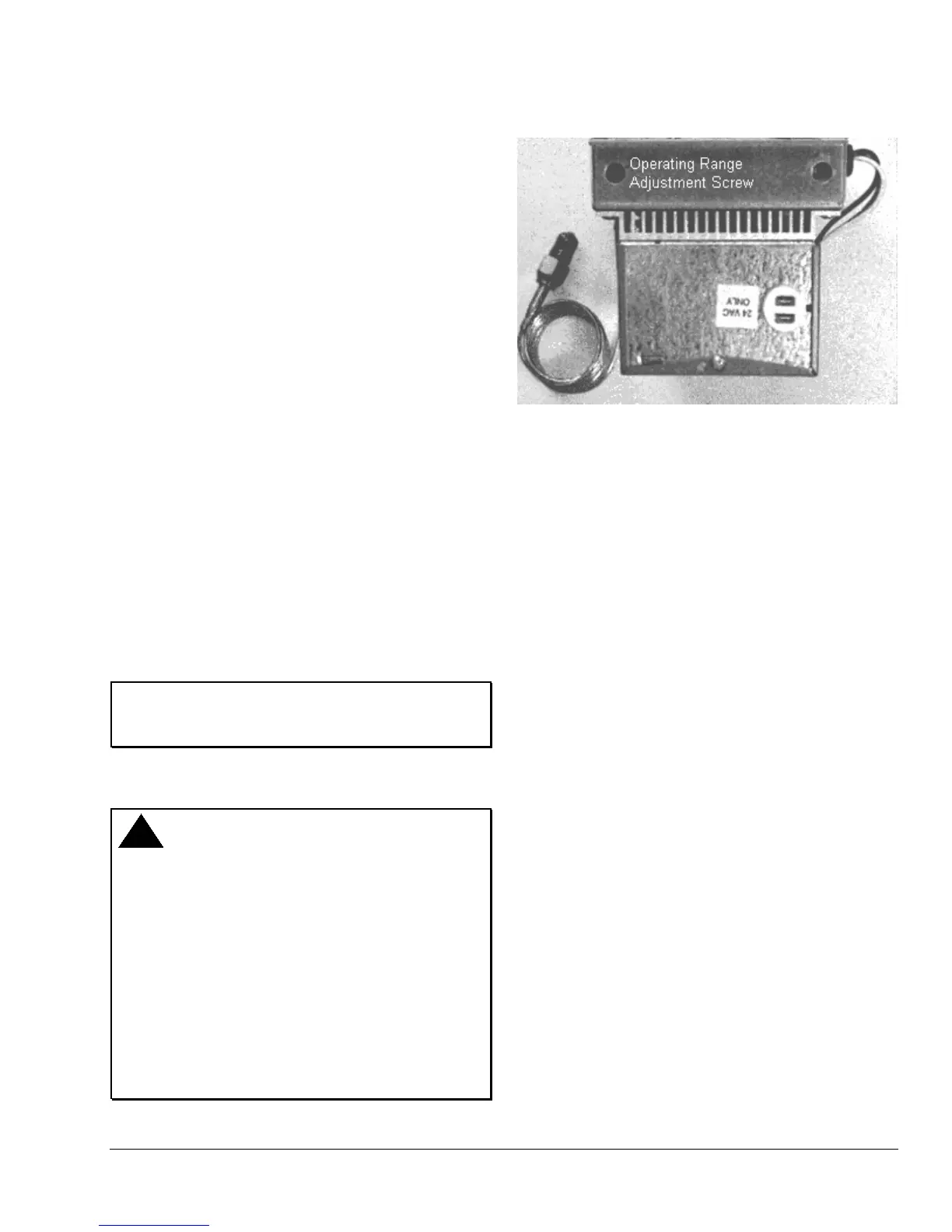

The P66 control’s throttling range is fixed and cannot

be adjusted. The operating range pressure is

adjustable within the control pressure range. See the

Technical Specifications table for P66 model pressure

ratings.

To adjust the operating range pressure:

1. Apply a reliable pressure gauge to the controlled

system to monitor the pressure adjustments.

2. Access the operating range adjustment screw for

the P66 pressure transducer through the opening

in the upper left-hand corner of the P66 control

base (Figure 5).

Note: On dual pressure models, access to the

second adjustment screw is located in the lower right-

hand corner of the control base.

3. Turn the adjustment screw 1/2 turn (or less)

clockwise to increase the operating range

pressure or 1/2 turn (or less) counterclockwise to

decrease the operating range pressure.

• Low Pressure Models (80 to 200 psig):

1/2 turn = approximately ± 9 psig (62 kPa)

• Medium Pressure Models (140 to 350 psig):

1/2 turn = approximately ± 18 psig (124 kPa)

• High Pressure Models (300 to 500 psig):

1/2 turn = approximately ± 35 psig (241 kPa)

IMPORTANT: Do not adjust the operating range

screw more than 1/2 turn before allowing the system

pressure to stabilize.

4. Check system pressure and repeat Step 3 until

the desired operating range pressure is attained.

CAUTION: Risk of Property Damage.

Limit any adjustments to two full turns in either

direction. Over-adjustment may prohibit modulation

of the motor resulting in high head pressures. All

pressure adjustments should be verified with the use

of refrigerant pressure gauges.

MISE EN GARDE: Risque de dégâts matériels.

Limiter tout réglage à deux tours complets dans

chaque sens. Un réglage excessif risque

d'empêcher la modulation du moteur, engendrant

des pressions de refoulement élevées. Tous les

réglages de pression doivent être vérifiés à l'aide

des manomètres de refrigerant.

Figure 5: Operating Range Adjustment Screw

Location

Checkout

Before leaving the installation, observe working

application for correct operation. See the Operation

section for a typical operational sequence.

Operation

Condensing unit installation, operation, and

maintenance determine the overall capability of

maintaining a satisfactory pressure by means of fan

speed control. Within the operating range, the P66

control provides air delivery in direct proportion to heat

rejection requirements. This allows the refrigeration

system to perform efficiently in very low ambient

temperatures.

The P66 pressure transducer provides direct response

to changes in condenser pressure, regardless of the

variations in fan delivery curves. The dual input

models select the pressure input from the transducer

sensing the highest pressure.

See Figure 6 for a typical operational sequence for a

P66 control.

Loading...

Loading...