PENNBARRY

41

Fan Laws

The following section includes engineering and technical data,

guidelines and system explanations related to air moving

and control devices. Fan laws and system descriptions are

consistent with industry standards, defi nitions and accepted

practices. This information is provided to assist system

designers in sizing, selecting and defi ning their air moving

and control systems as well as explaining variables inherent

in system design.

There are nine fan laws, three are of prime importance to the

understanding of ventilation systems. These, together with an

appreciation of fan types, should help avoid most problems

with poor airfl ow performance. These three laws assume the

same fan operating with air at a constant density.

1. Airfl ow and fan speed are directly proportional.

CFM1 is the original fl ow rate in cu. ft. per minute.

CFM2 is the desired fl ow rate in cu. ft. per minute.

RPM1 is the original rotational speed of the fan.

RPM2 is the desired rotational speed of the fan.

2. Pressure varies as the square of the fan speed

or airfl ow.

P1 is the original static pressure.

P2 is the desired static pressure.

3. Power varies as the cube of fan speed.

=

CFM

2

CFM

1

RPM

2

RPM

1

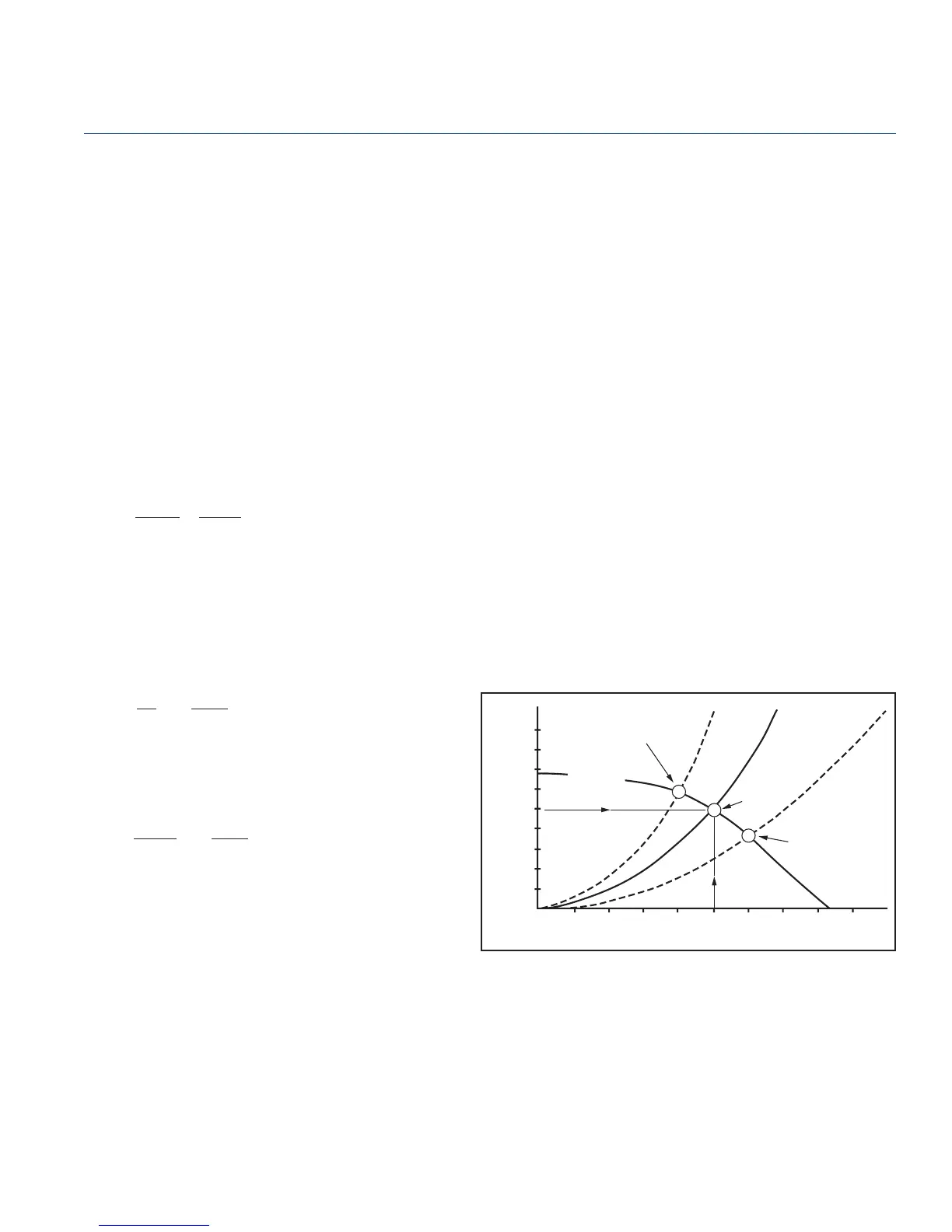

Interaction of Fan Curves and System Curves

A ventilation system using a Breezeway may consist of a fan

with duct connected to the inlet side. Control dampers, grilles,

registers and duct fi ttings may also be part of the system.

The fan is the component in the system which provides

energy to the airstream to overcome the resistance to fl ow

off the other components. The determination of the “pressure

loss” or “resistance to fl ow”, for the individual components

can be obtained from the component manufacturers. The

determination of pressure losses for ductwork and branch

ductwork design is well documented in standard handbooks,

such as the ASHRAE Handbook of Fundamentals.

The fan curve shown in Figure 1 is a typical fan performance

curve, developed through the actual testing of a fan in an

air tunnel. The fan is run at constant speed and constant air

density. When the fan is installed in the fi eld, then it becomes

part of the system. System curves are developed by using fi eld

tested data and applying fan laws. The point of intersection of

the system curve and the fan performance curve determines

the actual fl ow volume. If the system resistance has been

accurately determined, and the fan properly selected, the

performance curves will intersect at the system design point

(point A).

P

2

RPM

1

]

RPM

2

[

2

=

P

1

BHP

2

RPM

1

]

RPM

2

[

3

=

BHP

1

Engineering Notes

Breezeway

Figure 1

Interaction of System Curves and Fan Curve

CFM

Static Pressure - Inches W.G.

B

A

C

UNDER ESTIMATED S.P.

RESULTS IN HIGH STATIC

LOW C.F.M.

FAN CURVE

DUCT SYSTEM A

SYSTEM

DESIGN

POINT

OVER ESTIMATED S.P.

RESULTS IN LOW STATIC

HIGH C.F.M.

1.500

1.375

1.125

1.000

0.875

0.750

0.625

0.500

0.375

0.125

0

200 400 600 800 1000 1200 1400 1600 1800 2000

Loading...

Loading...