PENNBARRY

42

If the system resistance has been underestimated, then fan

curves and system curves will not intersect at the system

design point. They will intersect at lower CFM (point B). If the

system resistance has been overestimated, then the fan curve

system curve will intersect at a higher CFM than the system

design point (point C). (See Figure 1)

Effect of Change in Density, Altitude and Temperature

Correction Factors

The resistance of a duct system is dependent upon the density

of the gas fl owing through the system. A gas density of 0.075

lb/ft

3

is standard in the fan industry.

Pressure and horsepower vary directly as the ratio of the gas

density at the fan inlet to standard density. This density ratio

must always be considered when selecting fans. To select

a fan, pressure should be corrected to standard air density,

0.075 lb/ft

3

, 70ºF. at sea level. Static pressure at operating

condition x correction factor=static pressure at standard.

Refer to Table 1.

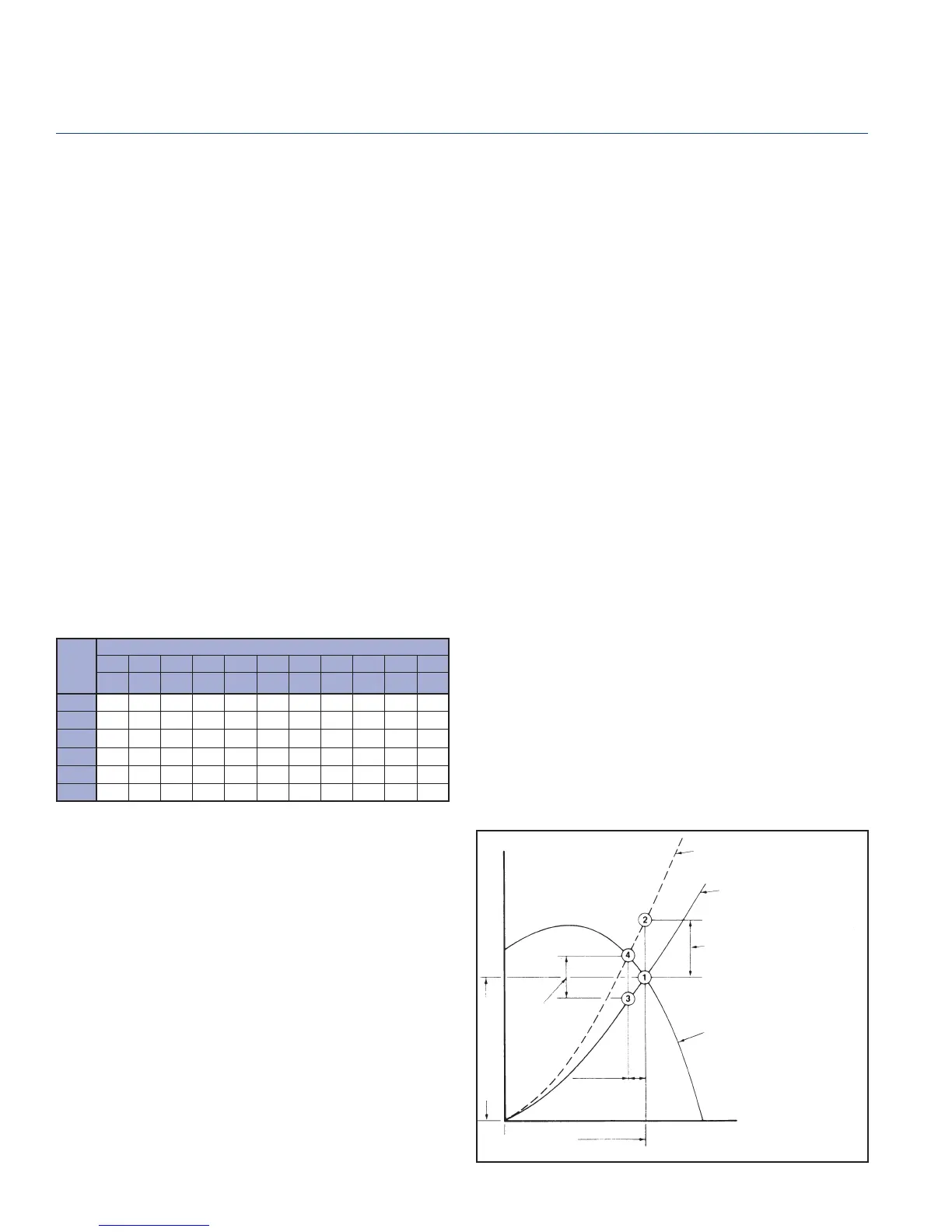

Table 1

Correction Factors

Unity Basis = Standard Air Density of 0.075 lb/ft

3

At sea level (29.92 in. Hg barometric pressure) this is equivalent to

dry air at 70°F.

Horsepower at standard ÷ correction factor = horsepower at

operating condition. Motors should be sized for highest density

conditions at which it is expected to operate.

Inlet System Effect

The most common installation problem is ductwork connection

to the inlet side of the fan. Here are several design criteria

for connecting ductwork to the fan. Keep a straight duct run

twice the diameter of the inlet size immediately before the

inlet of the fan. This will give the air a chance to straighten

out before entering the fan. Fan inlet swirl and non-uniform

inlet fl ow can often be corrected by inlet straightening vanes

or guide vanes. Restricted fan inlets located too close to walls,

obstructions or restrictions caused by a plenum or cabinet, will

decrease the useable performance of a fan. Cabinet clearance

effect or plenum effect must be considered a component

part of the entire system; the pressure losses through the

cabinet or plenum effect is considered as a System Effect

when determining system characteristics. The backdraft

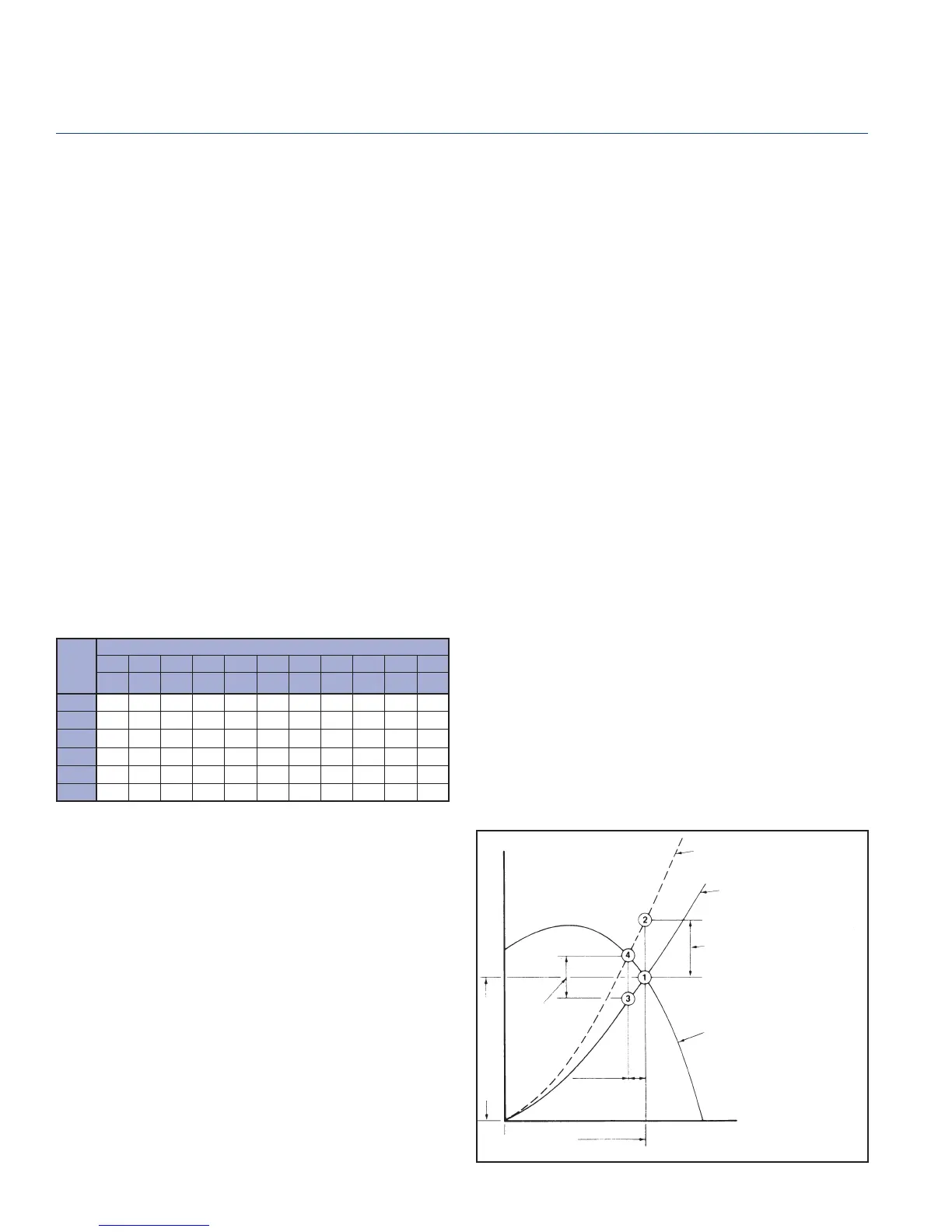

Figure 2

CURVE B - ACTUAL DUCT

SYSTEM WITH SYSTEM

EFFECT

CURVE A - CALCULATED DUCT

SYSTEM WITH NO ALLOWANCE

FOR SYSTEM EFFECT

SYSTEM EFFECT LOSS AT

DESIGN VOLUME

FAN CATALOG

PRESSURE-VOLUME

CURVE

SYSTEM

EFFECT AT

ACTUAL

FLOW

VOLUME

DEFICIENT

PERFORMANCE

Defi cient Fan/Duct System Performance System Effect Ignored

DESIGN VOLUME

DESIGN PRESSURE

TEMP

ºF

ALTITUDE (FEET) WITH BAROMETRIC PRESSURE (Inches Hg)

0' 500' 1000' 1500' 2000' 2500' 3000' 3500' 4000' 4500' 5000'

29.92 29.38 28.86 28.33 27.82 27.31 26.82 26.32 25.84 25.36 24.9

- 40 0.79 0.81 0.82 0.84 0.85 0.87 0.88 0.9 0.92 0.93 0.95

0 0.87 0.88 0.9 0.92 0.93 0.95 0.97 0.99 1 1.02 1.04

40 0.94 0.96 0.98 1 1.01 1.03 1.05 1.07 1.09 1.11 1.13

70 1 1.02 1.04 1.06 1.08 1.1 1.12 1.14 1.16 1.18 1.2

80 1.02 1.04 1.06 1.08 1.1 1.12 1.14 1.16 1.18 1.2 1.22

100 1.06 1.08 1.1 1.12 1.14 1.16 1.18 1.2 1.22 1.25 1.27

damper is part of external static pressure, and should be

accounted for when estimating system static pressure. Use

a motorized backdraft damper when the fan has a variable

speed controller.

System Effect

A System Effect Factor is a pressure loss which recognizes

the effect of fan inlet restrictions, fan outlet restrictions or other

conditions infl uencing fan performance when installed in the

system. Figure 2 illustrates defi cient fan/system performance

resulting from one or more undesirable fl ow conditions. It is

assumed that the system pressure losses, shown in system

curve A, have been accurately determined, and a suitable fan

selected for operation at Point 1. However, no allowance has

been made for the effect of the system connections on the

fan’s performance. To compensate for this System Effect, it

will be necessary to add a System Effect Factor (SEF) to the

calculated system pressure losses to determine the actual

system curve. The SEF for any given confi guration is velocity

dependent and will, therefore, vary across the range of fl ow

volumes for the fan.

In Figure 2, the point of intersection between the fan

performance curve and the actual system curve B is Point

4. The actual fl ow volume will, therefore, be defi cient by the

difference from 1-4. To achieve design fl ow volume, an SEF

equal to the pressure difference between Point 1 and 2 should

have been added to the calculated system pressure losses and

the fan selected to operate at Point 2. Note that because the

System Effect is velocity related, the difference represented

between Points 1 and 2 is greater than the difference between

Points 3 and 4.

The SEF includes only the effect of the system confi guration

on the fan’s performance.

Engineering Notes

Breezeway

Loading...

Loading...