14DBP-001 21

Suspensions & Brakes

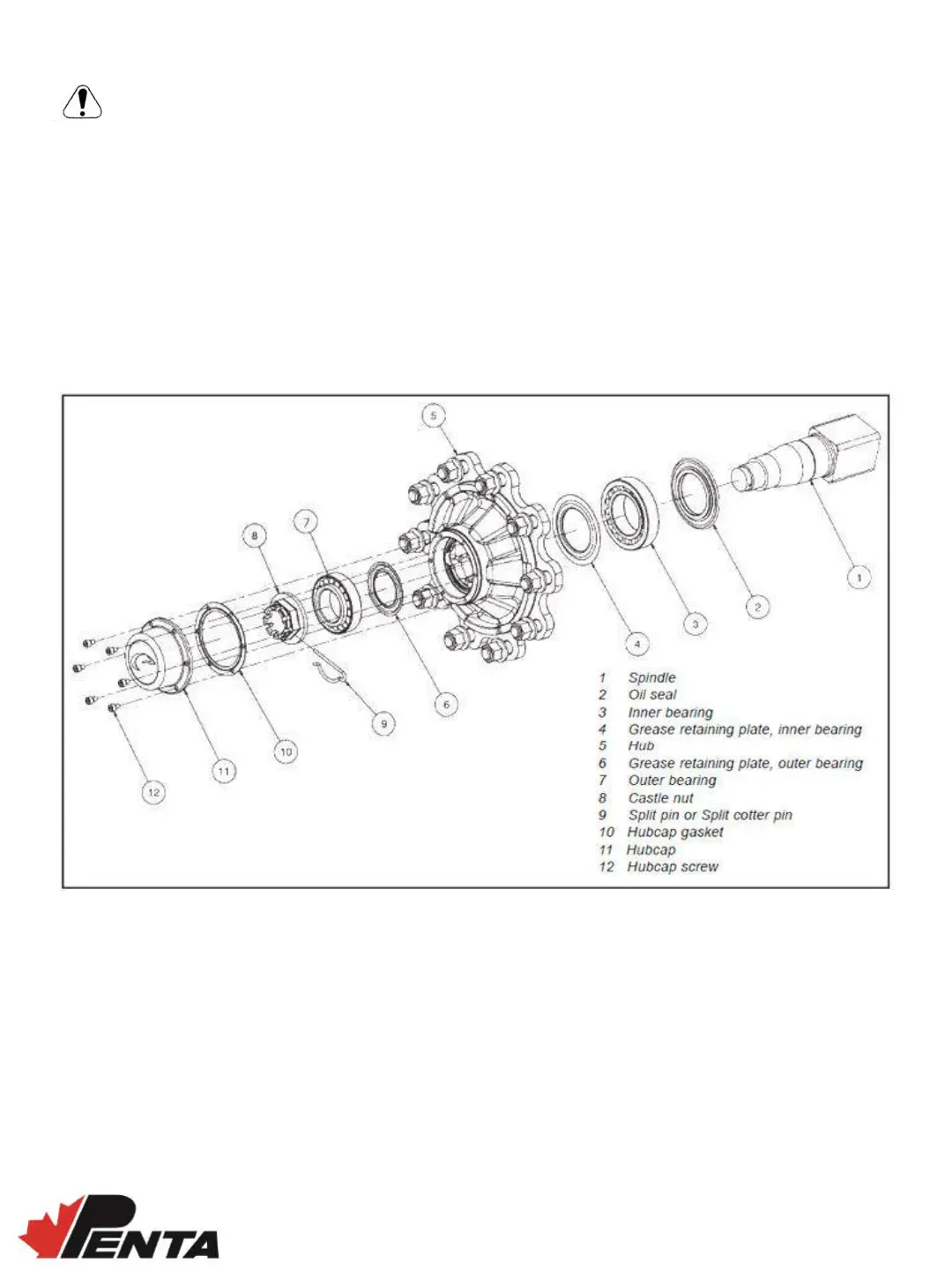

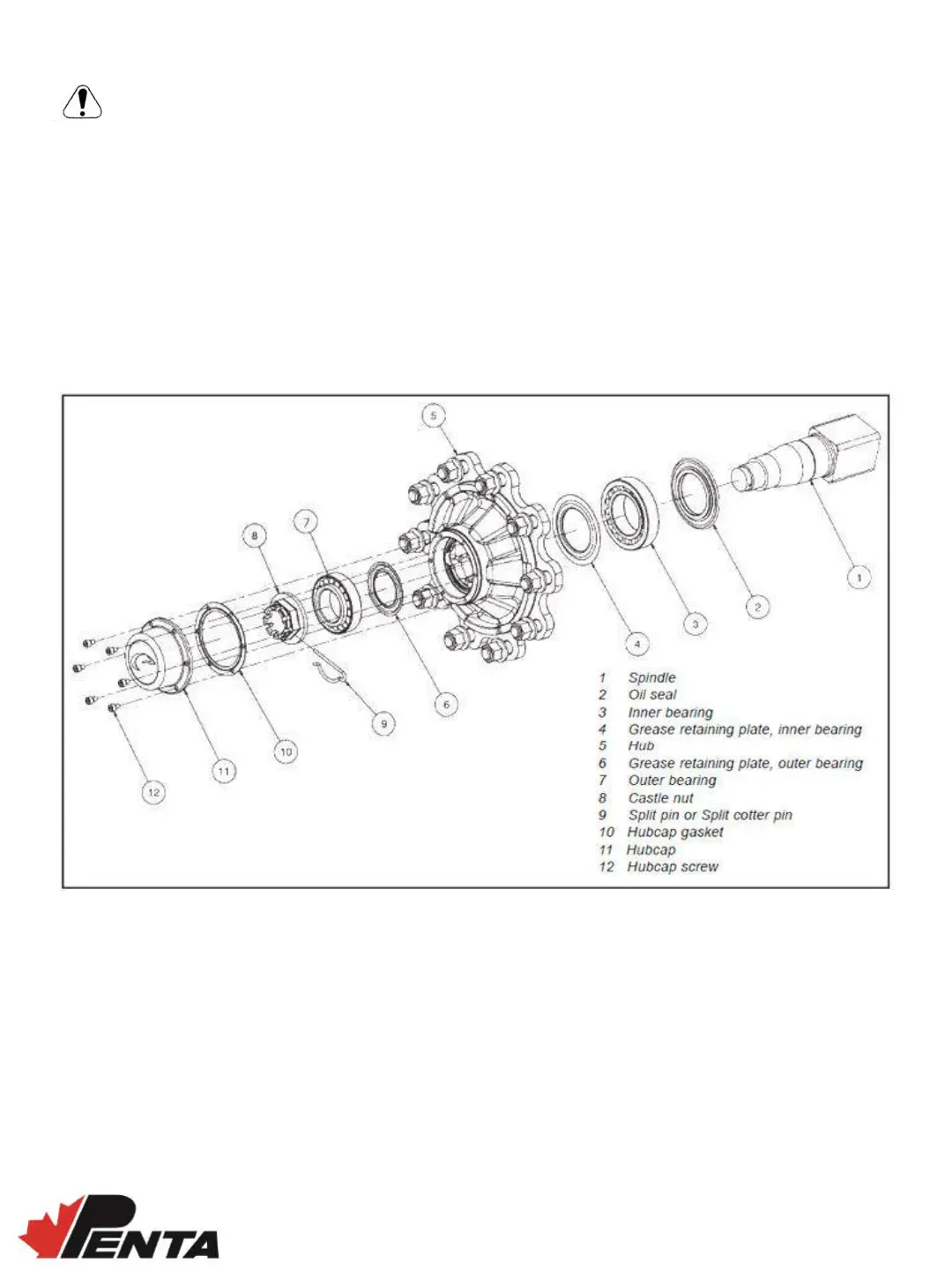

LUBRICATING THE WHEEL BEARINGS

Every 2 Years

In normal operating conditions, lubricate the bearings every 2 years or every 50,000 km and when

the brake shoes are replaced.

In harsh conditions the bearings should be lubricated more frequently.

Use a general purpose EP grease formulated for lubricating plain, ball and roller bearings, subject

to heavy loads and impacts typical of HGV, agricultural vehicle hubs, etc.

All parts (hub, spindle, bearings, seals, castle nuts, hubcap, cotter pin) should be degreased and

Perfectly clean before reassembly.

The work should be carried out in a clean environment with appropriate tools as the slightest bit

of dirt can

Damage the bearings or even the spindle.

When carrying out maintenance on the bearings, check the brake linings, drum and return

springs, clean the brakes, clean and lubricate the brake cam shaft.

BRAKE MAINTENANCE & ADJUSTMENT

Initial checks

The brakes should be tested before using for the first time and after the first laden journey:

Check the actuator and return spring mountings, check the actuator stroke and return travel

and check that the road and parking brakes operate and release correctly.

Tighten the screws and nuts (covers, fulcrum, etc), check the cotter pins, pins, circlips, etc.

Check for hydraulic fluid and air leaks.

Every 3 Months

Loading...

Loading...