Installation 4

Before you install your pump

NOTICE:Wellmustnotbemorethan20’depthtowater.

1. Longrunsandmanyfittingsincreasefrictionandreduceflow.Locate

pump as close to well as possible: use as few elbows and fittings

aspossible.

2. Be sure well is clear of sand. Sand will plug the pump and void

thewarranty.

3. Protect pump and all piping from freezing. Freezing will split pipe,

damage pump and void the warranty. Check locally for frost protection

requirements(usuallypipemustbe12”belowfrostlineandpumpmust

be insulated).

4. Be sure all pipes and foot valve are clean and in good shape.

5. Noairpocketsinsuctionpipe.

6. Noleaksinsuctionpipe.UsePTFEpipethreadsealanttapetoseal

pipejoints.

7. Unionsinstallednearpumpandwellwillaidinservicing.Leaveroom

to use wrenches.

8. Risk of explosion. Pump body may explode if used as a

boosterpump.DONOTuseinaboosterapplication.

NOTICE:Usetheinstallationmethodwhichmatchesyourwelltype.

9. Installacheckvalveinthepumpsuctionport.Besurethattheflow

arrow points toward the pump. Failure to install a check valve on the

inlet side of the pump may allow the pump body to drain between

pump cycles, causing dry running, seal or internal failure, and voiding

the warranty.

Pump

Body

From

Well

Dirt and Scale Plug Pump and Pipes!

Use New Pipe for Best Results.

Clean Flow!

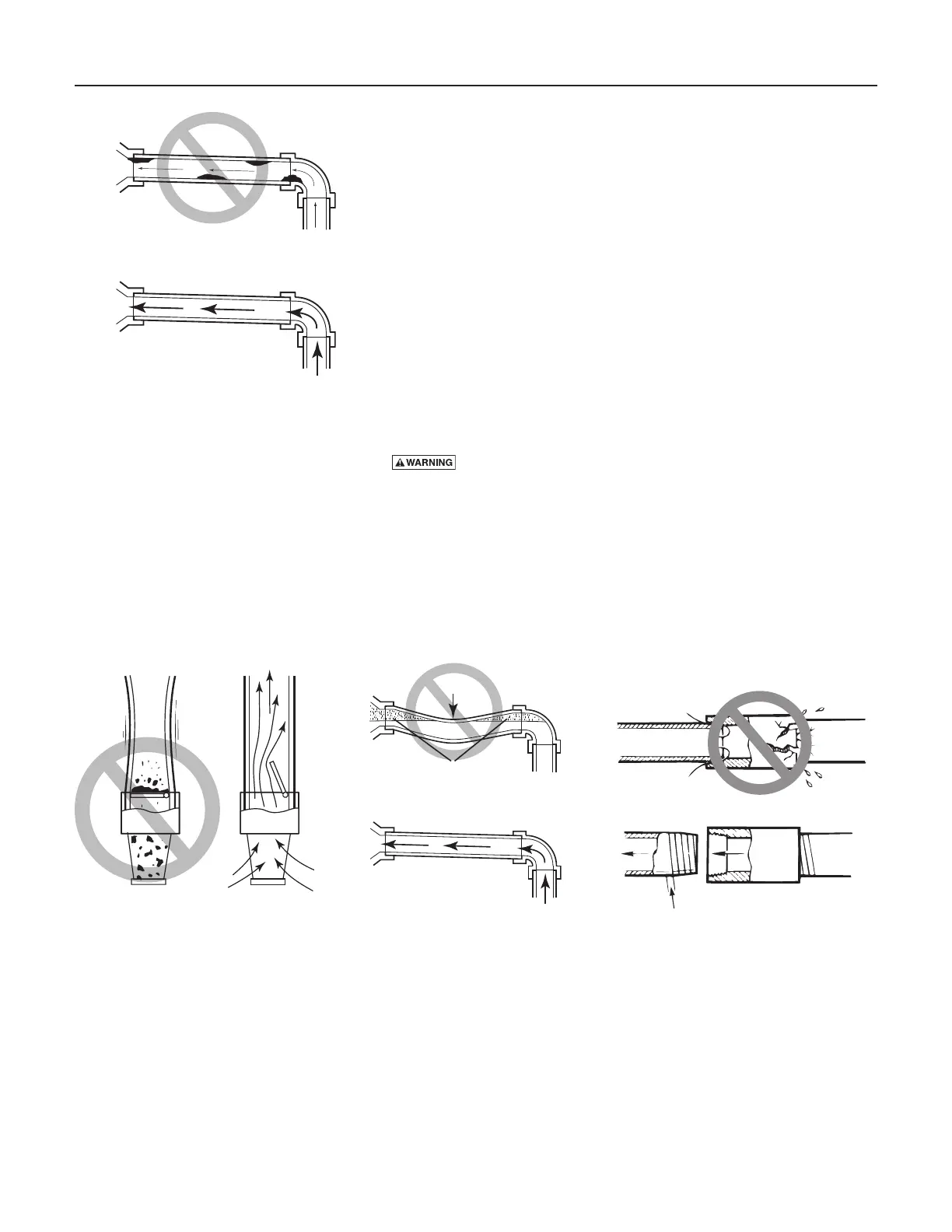

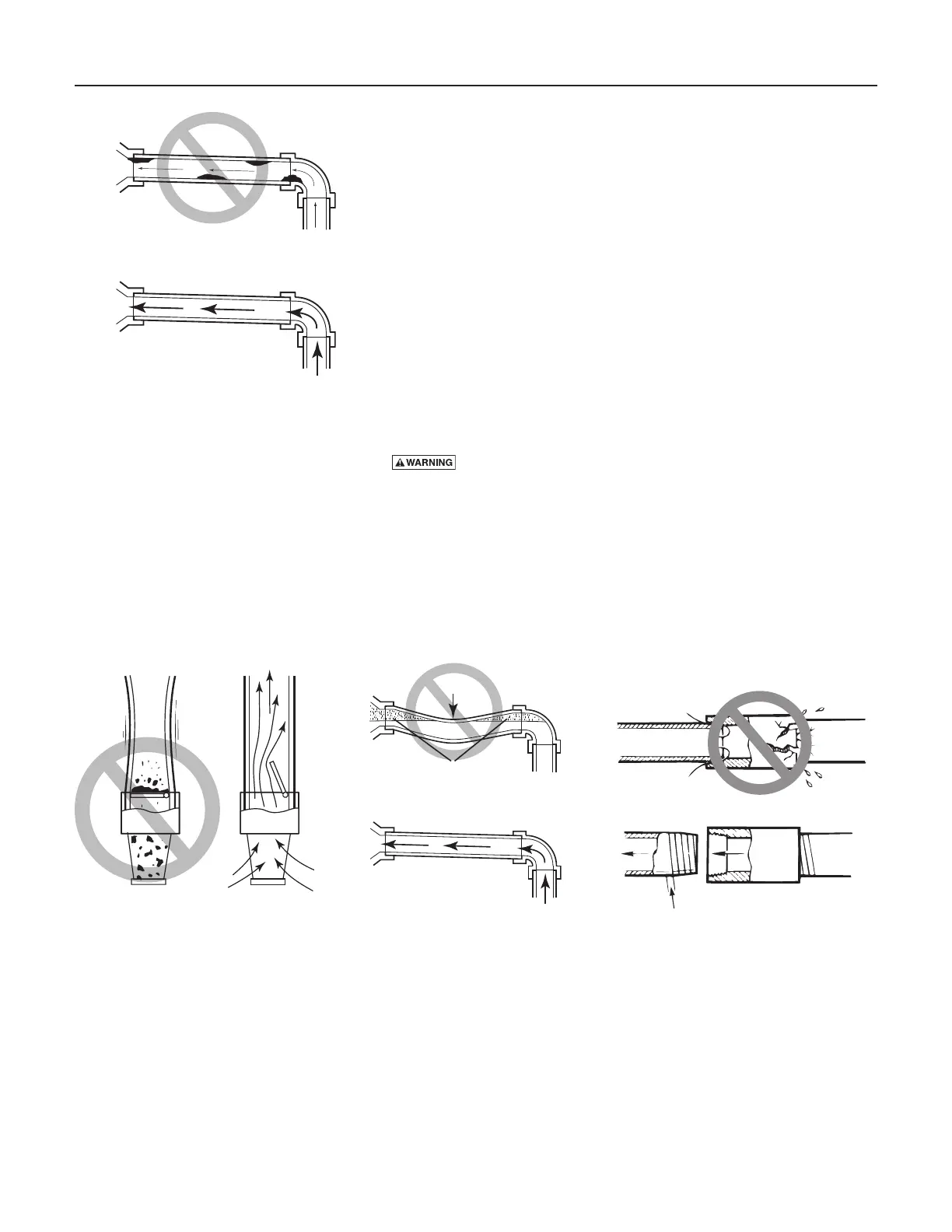

Figure 1 – No Dirt or Scale in Suction

Pipe

Figure 2 – Foot Valve Must Work

Freely

Figure 3 – No Air Pockets in Suction

Pipe

No Sags

Sags Allow Air Pockets

If Air Pockets Form, Water Won’t Flow.

Keep Pipe Straight and Angled up to Pump.

No air leaks In

Suction pipe.

If air flows

water won’t

Use PTFE tape.

Use PTFE pipe thread sealant tape or pipe joint

compound approved for use on PVC.

Figure 4 – Suction Pipe Must Not Leak

Loading...

Loading...