3

pulled, it may be necessary to shift cord leads back and forth

to guide the insulated terminals through the hole in the motor

housing. Once the terminals have cleared the hole, gently pull

cord until terminals are completely outside motor housing. Then

simply disconnect terminals to remove cord.

To install new cord, reconnect terminals (black to black, white to

white, green to green), and guide terminals back through hole

in motor housing. Once terminals have passed through the hole,

retighten the cord nut into housing. Tighten nut firmly but do not

overtighten.

The power cord should be replaced if it has been damaged in any

way or the cord jacket has become brittle with age.

MOTOR TYPE

The D1C20-21 Series grinder pump contains a 3/4 frame, 2 HP,

single phase, 60 Hz, 3450 RPM, capacitor start - capacitor run

motor with Class F insulation and built-in on-winding overload

protection. Motor has upper and lower ball bearings and is oil-

cooled and lubricated. Resistance at motor leads is 9.7 ohms.

n CAUTION! THE D1C20-21 SERIES GRINDER PUMP SHOULD

NEVER BE WORKED ON WITHOUT FIRST DISCONNECTING THE

POWER CORD.

OIL TYPE

The motor housing contains dielectric

transformer oil to provide good heat

transfer and lubrication of ball bearings;

no other lubrication is required. Oil level

may be checked by removing the nut

(item 15C) and washers from the top

of the motor housing. The oil should be

filled to the bottom of the end shield

(see figure 1). Do not overfill with oil.

Only dielectric transformer oil obtained

from an authorized service center

should be used.

PUMP SWITCH INSTALLATION

INSTRUCTIONS

NOTE: In accordance to third party approval, pump must be

submerged a minimum of 8-1/2" from bottom of the legs on volute

case during operation.

MOUNTING THE SWITCH

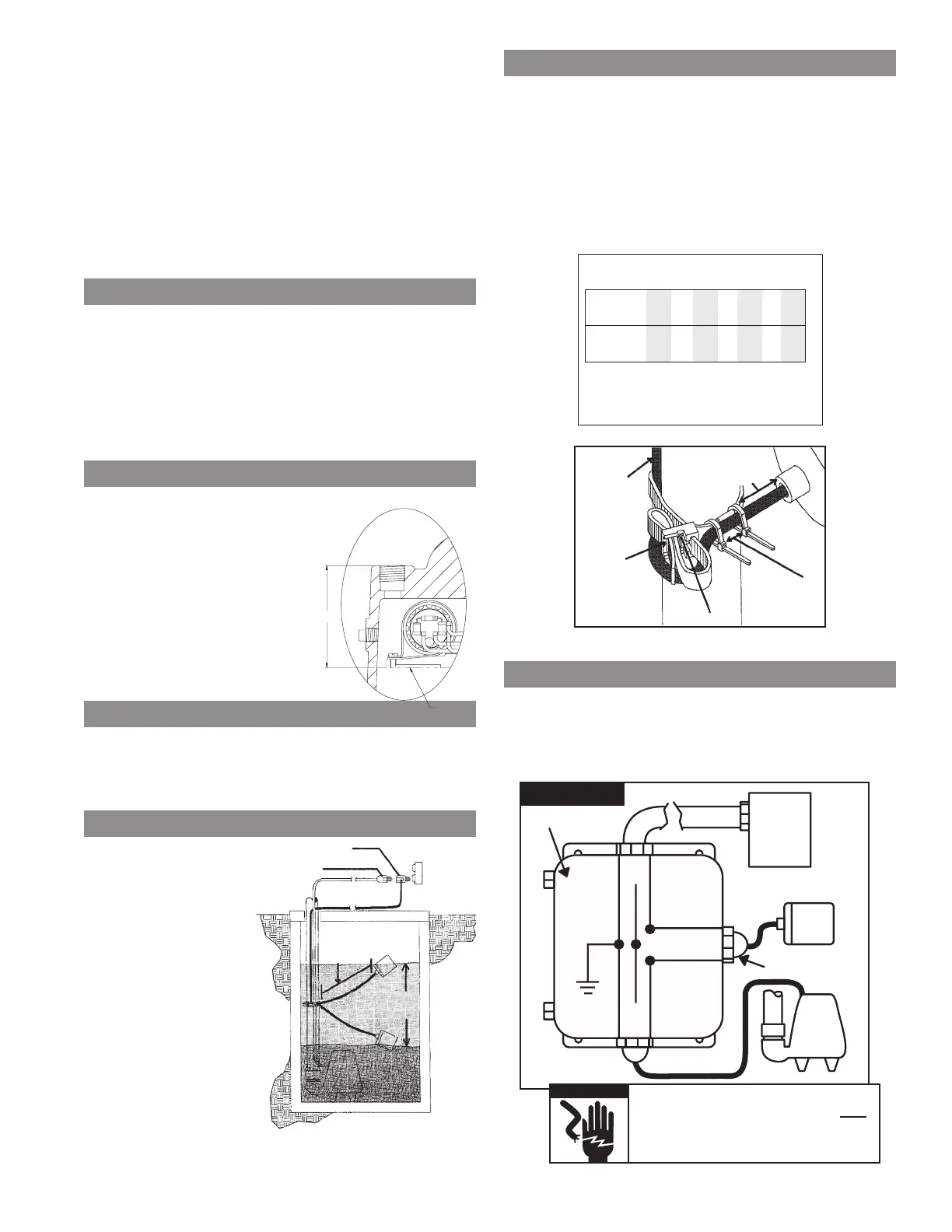

1. Determine pumping

range for installation

(see Figures A and B).

Do not tether less than

3-1/2" (9 cm) from

pipe.

2. Tighten strap around

discharge pipe keeping

switch cable between

strap and pipe to

prevent slippage (see

Figure C).

3. Space small ties at

least 1" (2.5 cm) apart

(see Figure C). To read-

just ties, press small tie

tabs down.

4. To lock releasable tab, run remaining strap between tab and

head. Tuck strap back through head (see Figure C).

PIGGYBACK PLUG INSTALL

n Electrical outlet must not be located in pump chamber.

n Electrical outlet voltage, piggyback plug voltage, and pump

voltage must match.

1. Follow steps 1 through 4 of “Mounting the Switch.”

2. Insert switch’s piggyback plug into outlet.

3. Plug pump into piggyback plug (see Figure A).

4. Check installation. Allow system to cycle to ensure

proper operation.

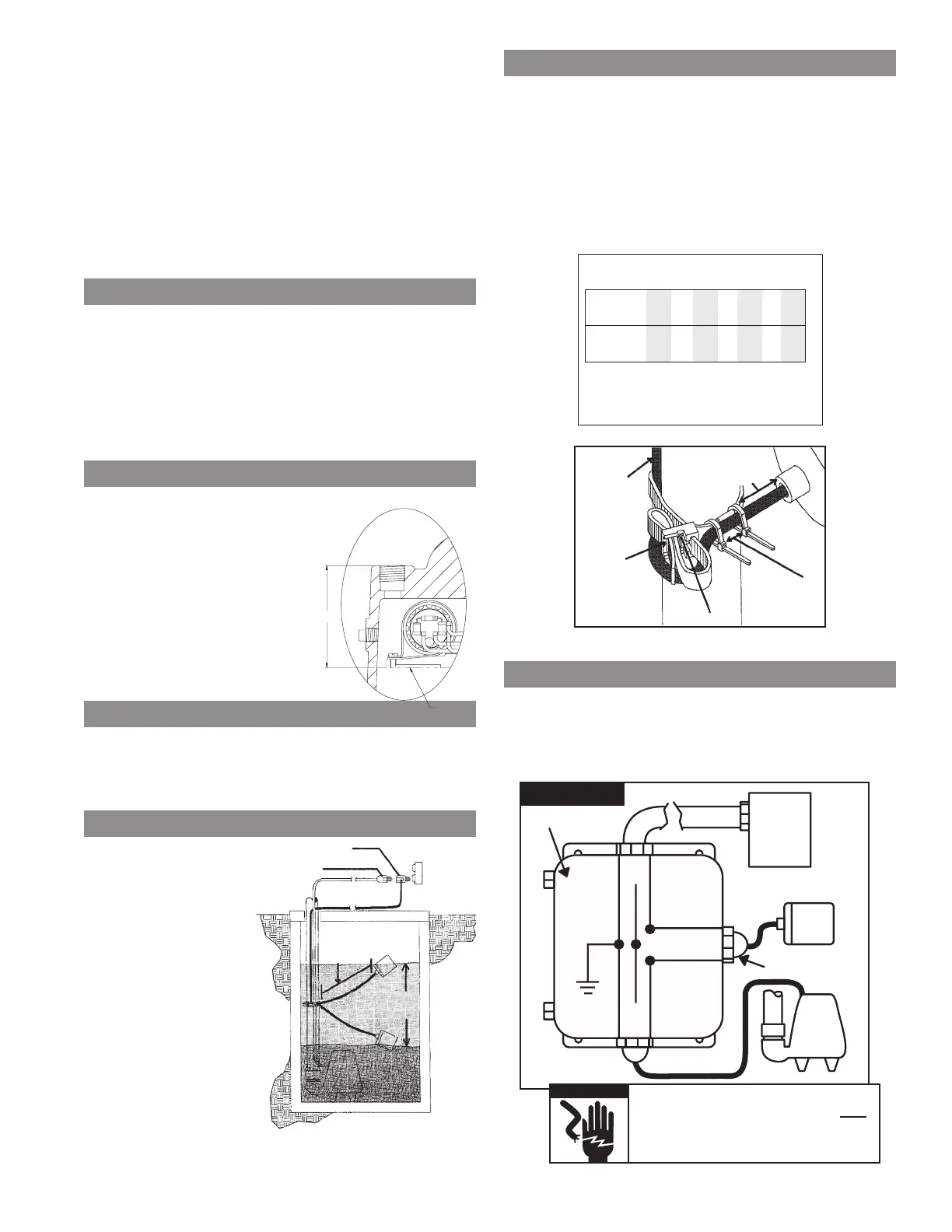

DIRECT WIRE INSTALL

1. Follow steps 1 through 4 of “Mounting the Switch.”

2. Wire switch as shown below.

3. Check installation. Allow system to cycle to ensure

proper operation.

pump plug

switch plug

tether

length

pumping

range

Fig. A

Determining Pumping Range

In Inches (1 inch = 2.5 cm)

tether

3.5 6 10 14 18 22 24

length

pumping

7 10 16 22 28 33 36

range

Use only as a guide. Pumping ranges are based on

testing in nonturbulent conditions. Range may vary

due to water temperature and cord shape. Note: As

the tether length increases, so does the variance of the

pumping range.

Fig. B

Fig. C

secure

cable

under

strap

strap

head

space ties

1 inch

(2.5 cm) apart

releasable tab

3.5 inch (9 cm)

minimum

tether length

liquid-tight

connector

230V

pump

230V

power

source

junction

box

black

white

L1

L2

G

G

L1

L2

G

230 VAC

In 230 VAC pump installations, one side of

the line going to the pump is always HOT.

This condition exists if the switch is on or

off. Install double pole disconnect on all

230 VAC pump circuits.

n WARNING

Loading...

Loading...