7 SHURFLO WATER BOOST MODULAR FILTRATION SYSTEM INSTALLATION AND OPERATION GUIDE

SYSTEM STARTUP AND OPERATIONS CONTINUED

Plumbing Procedure

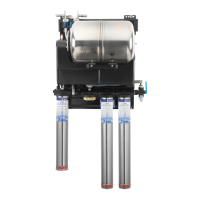

Please refer to the image below, as reference is made throughout this procedure to these components.

Main City

Water Inlet

Ice Maker

Water Supply*

*Ice Maker Water Supply is non-boosted/non-filtered

Water Out

Non-Carb System

Water Out

to Carbonator

WBMF System Out

Ball Valve

3

Filter Head

Assembly

4

Bypass

Plug/Cap

5

Filter Canister

stainless steel sump

6

Filtered Water

Pressure Gauge

7

Purge Valve

w/o drain tubing

attached

8

Booster Pump

(behind shroud)

9

Tank Pre-charge

Valve and Cap

10

Pressure Relief

Valve

2

City Water In

Ball Valve

1

Ice Filter Canister

stainless steel sump

11

1. Position both inlet and outlet globe-valves to the

off position.

2. Connect incoming city water supply line to inlet

shut-off valve.

If icemaker is being installed, follow steps 3 and 4.

If icemaker is not being installed, proceed to step 5.

3. Remove plugged icemaker supply from line inlet

globe-valve.

4. Connect icemaker supply line to the inlet globe-valve.

5. Connect carbonator supply line to outlet globe-valve.

If installing non-carbonated valves on dispense unit

follow steps 6 and 7.

If non-carbonated valves are not being installed,

proceed to step 8.

6. Remove plugged non-carbonated supply line from outlet

of globe-valve.

7. Connect non-carbonated supply line to outlet of

globe-valve.

8. Install inline water pressure reducer valve just prior to the

inlet fitting of the carbonator pump.

Pentair

®

Shurflo

®

inline water pressure reducer valves

are recommended for all water boost modular system

installations. For additional information regarding the water

pressure reducer valve please refer to Pentair Shurflo

document 911-380.

9. Turn the purge valve to the off position.

10. Check pre-charge pressure of accumulator tank for

proper pressure – add additional pressure if required

using air only (do not pre charge accumulator with CO

2

).

50 psi pre-charge pressure is recommended for carbonated

beverage installations.

11. Manually open and close pressure relief safety checking

for proper functioning.

12. Uncoil purge line and put into bucket or drain.

13. Turn on incoming city water supply and inlet globe-valve.

14. Outlet globe-valve should still be in the off position.

Inspect properly connected water supply line to icemaker.

15. Connect power supply to water boost pump.

16. Turn the purge valve to the open position.

17. Purge system until all air is evacuated and a steady water

flow is present.

18. Turn purge valve to the off position.

19. Recoil and secure purge line to system.

20. Allow water boost pump to cycle off

Please follow all Beverage OEM standard startup procedures

for carbonated system applications.

21. Check system for water leaks.

22. Turn the outlet globe-valve to the on position.

23. Check for proper operation of icemaker, carbonator and

non-carbonated dispense valve operation.

(continued)

Loading...

Loading...