9 SHURFLO WATER BOOST MODULAR FILTRATION SYSTEM INSTALLATION AND OPERATION GUIDE

SYSTEM STARTUP AND OPERATIONS CONTINUED

Filter Replacement and Preventive Maintenance Procedure (continued)

19. Allow water boost pump to cycle OFF.

20. Position purge valve tubing into bucket or drain.

21. Turn the purge valve to the ON position.

22. Purge system until all air is evacuated and steady water

flow is present.

23. Turn the purge valve to the OFF position.

24. Recoil purge tubing and secure to system.

25. Allow the water boost pump to cycle OFF.

26. Open outlet globe valve to dispense unit and non – car-

bonated valve.

27. Reconnect power supply to carbonators.

28. Check for proper cycling of carbonator and flow rate of

non–carbonated valve.

SANITIZING

It is recommended that all Pentair

®

Shurflo

®

Water Boost Modular Filtration Systems be sanitized under the following

conditions:

• The fountain dispense system is diagnosed with an off taste or odor.

• The local municipality has recognized a water related concern in the store location.

• The water boost modular system is being disconnected from service for storage.

• The water boost modular system is being reinstalled after being stored.

• Seasonal startup or shutdown on location.

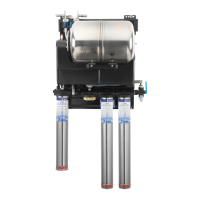

The image below shows the proper set up to conduct the sanitization procedure, which steps follow next.

Connect tubing to inlet port.

Insert free end into bucket of

sanitizing solution

Connect tubing to outlet

port to run sanitizing

solution out to drain

Bypass plugs

(inverted stainless steel sumps)

Sanitizing Solution

• 10 gallons hot (120/140 f) water

• 10 oz. non-sudsing detergent

• 5 oz. Bleach

1. Pour 10 gallons of hot water (120 – 140˚F) into two five (5)

gallon buckets mixing in each bucket, five (5) ounces of

non-sudsing, non–scented dishwashing detergent and

2.5 oz of common chlorine bleach

2. Disconnect power supplies to the carbonators being

supplied by the filtration system being serviced.

3. Disconnect power supply to the water boost pump

(and ice maker if applicable).

4. Turn OFF and disconnect incoming city water supply to

inlet shutoff valve of system.

5. Turn OFF outlet water supply valve.

6. Activate one non-carbonated dispense valve on each

dispense unit all water pressure is depleted

7. Disconnect inlet and outlet water supply lines from inlet

and outlet shutoff valves (leave icemaker supply line

connected).

8. Remove all stainless steel sumps and filter cartridges

from the system.

Refer to prior guidelines for stainless steel sump and

cartridge removal.

Loading...

Loading...