WCS* Read Head Position Encoding System

Product Description

2020-01

11

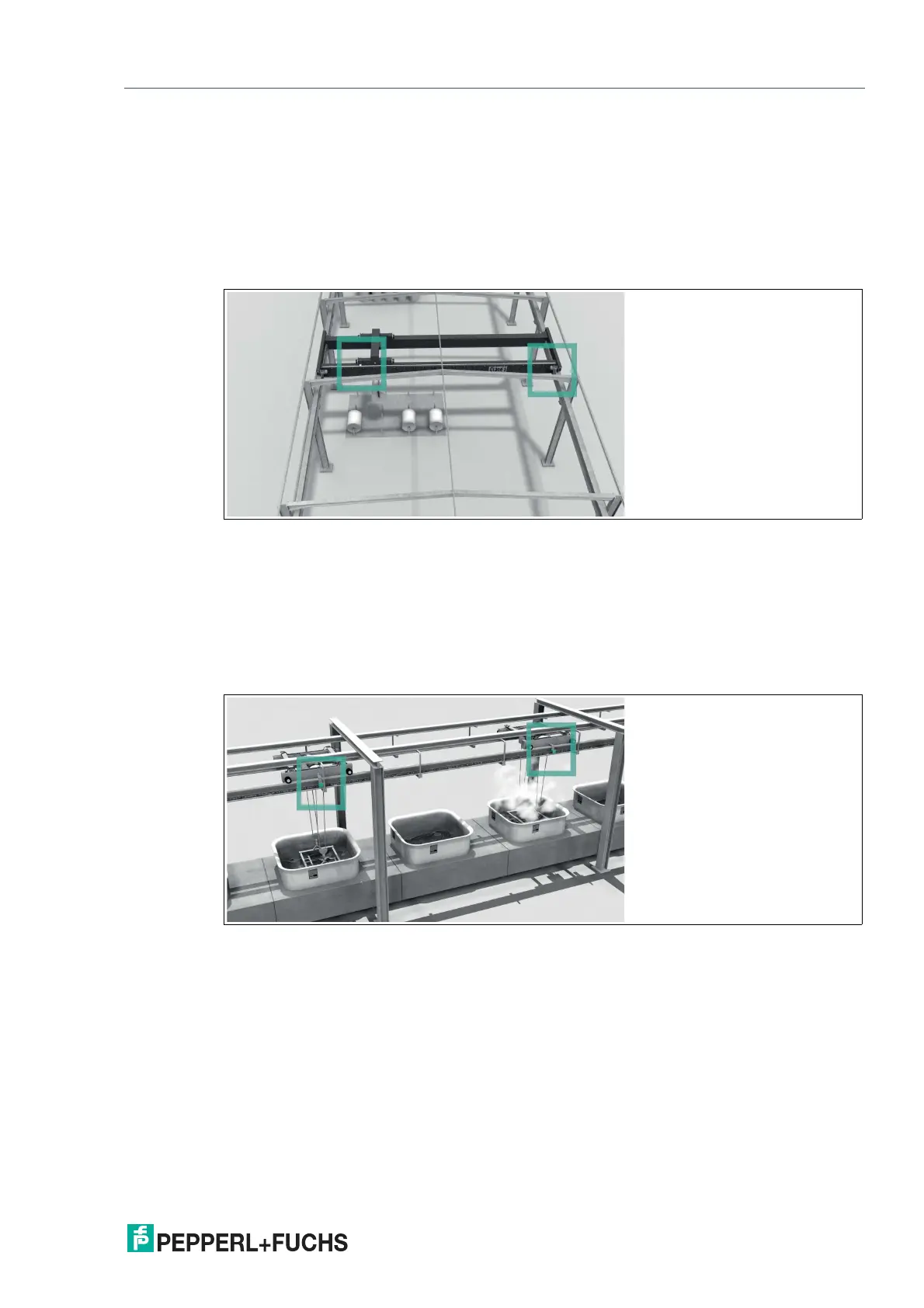

Automatic Cranes

Automatic cranes are a typical application for the WCS2 in conjunction with the aluminum pro-

file system. The crane is positioned using one read head each for the crane and the trolley

movement. At each point, the guide trolley ensures the optimal position of the read head in

relation to the code rail and decouples any vibrations from the crane track. Optional cleaning

brushes for the code rail can be attached to the guide trolley. This means that the WCS can be

used in a very dusty environment, such as in cement works or foundries. If the cranes are used

outdoors, the WCS3 is used with a special protective enclosure.

Figure 2.2 Automatic crane

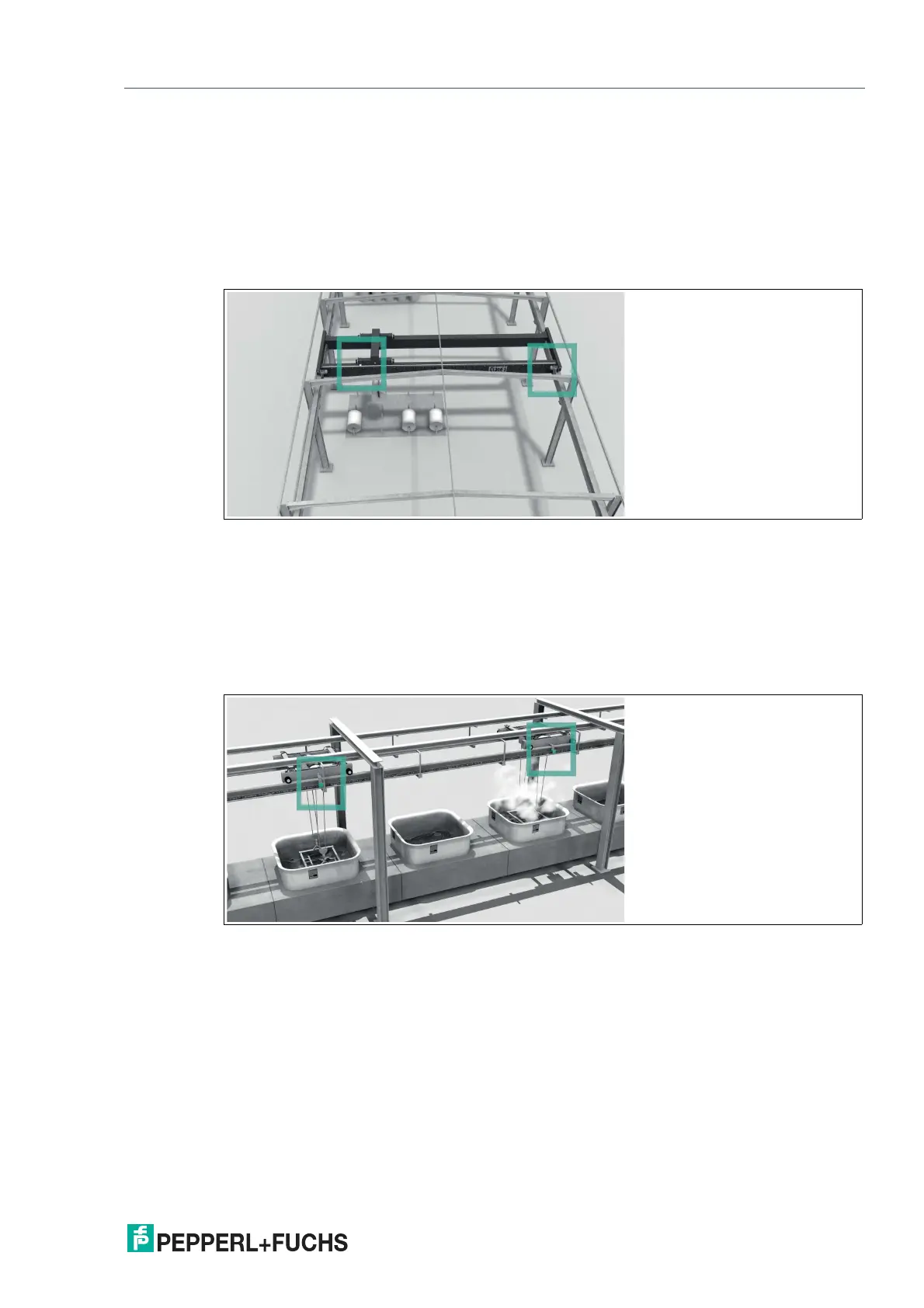

Galvanic Plants

One or more vehicles in succession moving along a straight route. The vehicles automatically

bring the material to be galvanized into the corresponding bath. The high and adaptable light

output of the read heads has enabled the WCS position encoding system to perform extremely

well even under these difficult conditions. The WCS3 with protective enclosure is ideal for gal-

vanic plants. In addition to degree of protection IP69, the enclosure is resistant to acids and

alkalis.

Figure 2.3 Galvanic plant

Loading...

Loading...