1/01 E Service Instructions 7

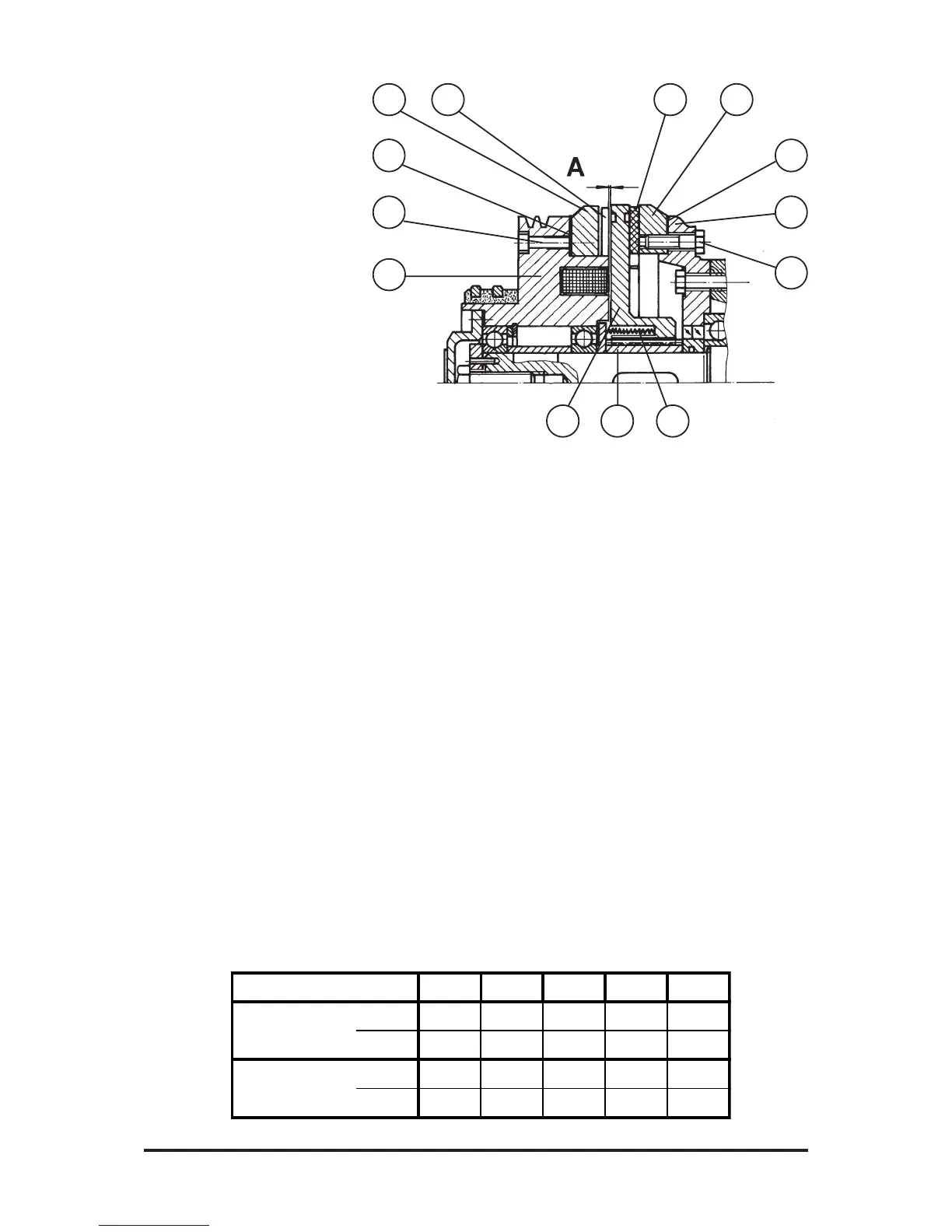

Checking and Setting the Air

Gap

Under normal operating condi-

tions, the air gap should be

checked once per year.

For air gap A, refer to the Table

(Fig. 5).

• Engaged state (clutch "ON"):

If air gap A min is smaller than

specified in the Table, Fig. 5,

shims 10 of uniform thickness

should be inserted

between coil body 7 and friction

ring 8 (Fig. 4) for

machine sizes 76 and 92, or

between friction ring 8 and

spacing segment 9 (Fig. 3) for

machine sizes 115 and 132.

For this purpose, slacken screws

11 around the circumference and

then re-tighten them uniformly.

The shims are available in vari-

ous thicknesses. Refer to the

Spare Parts Catalogue in the

Operating Instructions manual.

After the successful installation

of the shims, make sure that air

gap A max specified in the Table

is not exceeded (use thinner

shims) and air gap A min in the

braked state (clutch "OFF") is not

undercut.

Checking the Bearing Play

For machine sizes 115 and 132

only.

De-energize the clutch.

No perceptible play in the bear-

ing must appear when the fly-

wheel rim top is pulled and pushed

by hand.

In case of evident play, replace

the antifriction bearings.

Caution!

Bring the knife beam to its low-

ermost position prior to dis-

mantling the clutch/brake as-

sembly, as the brake becomes

ineffective when the compres-

sion springs are relieved.

Fig. 4

8

7

2 1 6

3 4 5

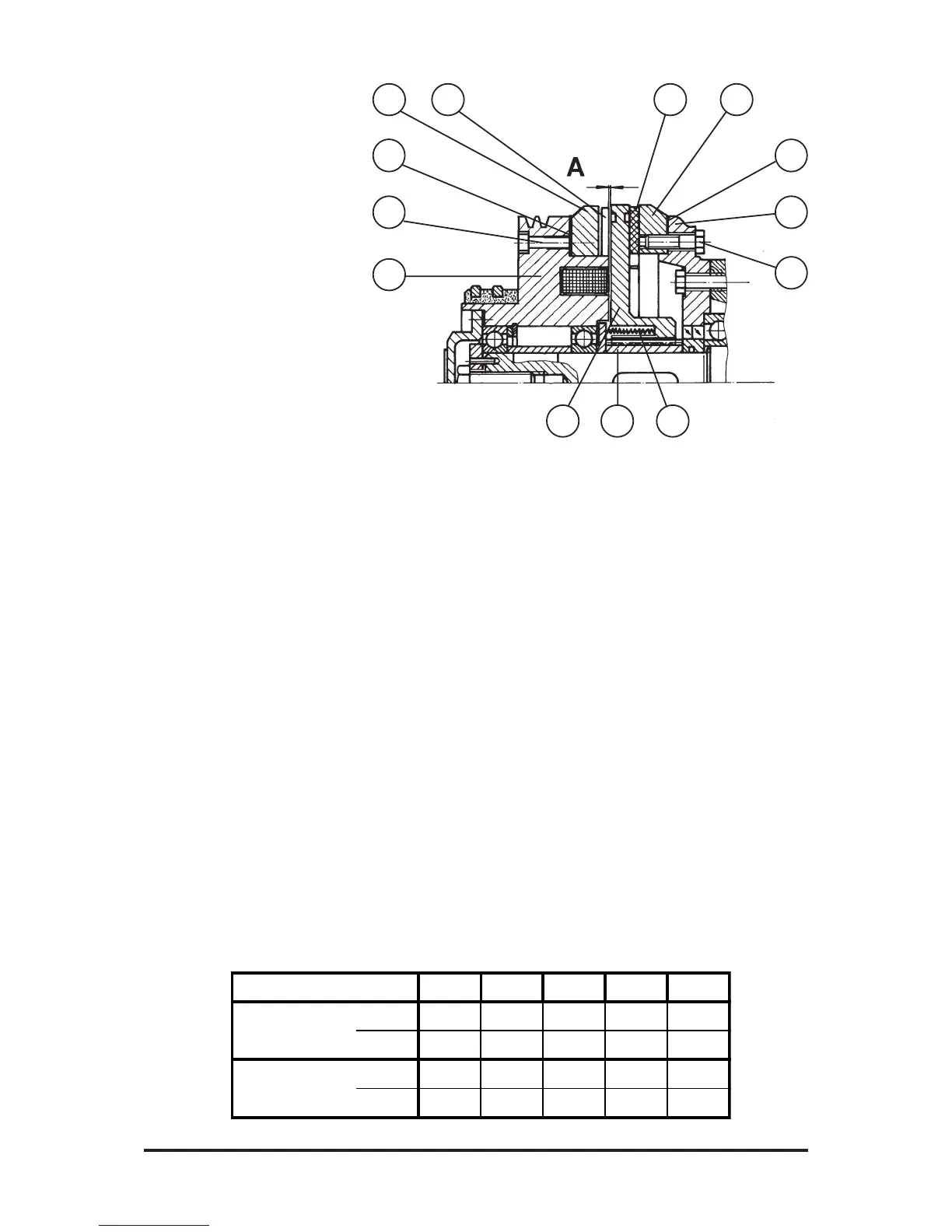

Fig. 5

Knife Drive Clutch/Brake Assembly Air Gaps ( mm )

Braked state (clutch "OFF")

If air gap A max is wider than

specified in the Table, shims 12

of the same thickness should be

inserted between brake ring 6

and gearbox cover 14. For this

purpose, energize the clutch as

described in the Operating In-

structions manual under "Manual

Cranking", slacken screws 13

around the circumference, and

then re-tighten them uniformly.

1411

10

13

12

Machine Size

76 92 115 132 168

Clutch "ON"

A min 0,2 0,2 0,2 0,2 0,2

A max 0,4 0,5 0,5 0,5 0,6

Clutch "OFF"

A min 0,6 0.7 0,7 0,7 0,7

A max 0,8 1 1,2 1,2 1,4

Loading...

Loading...